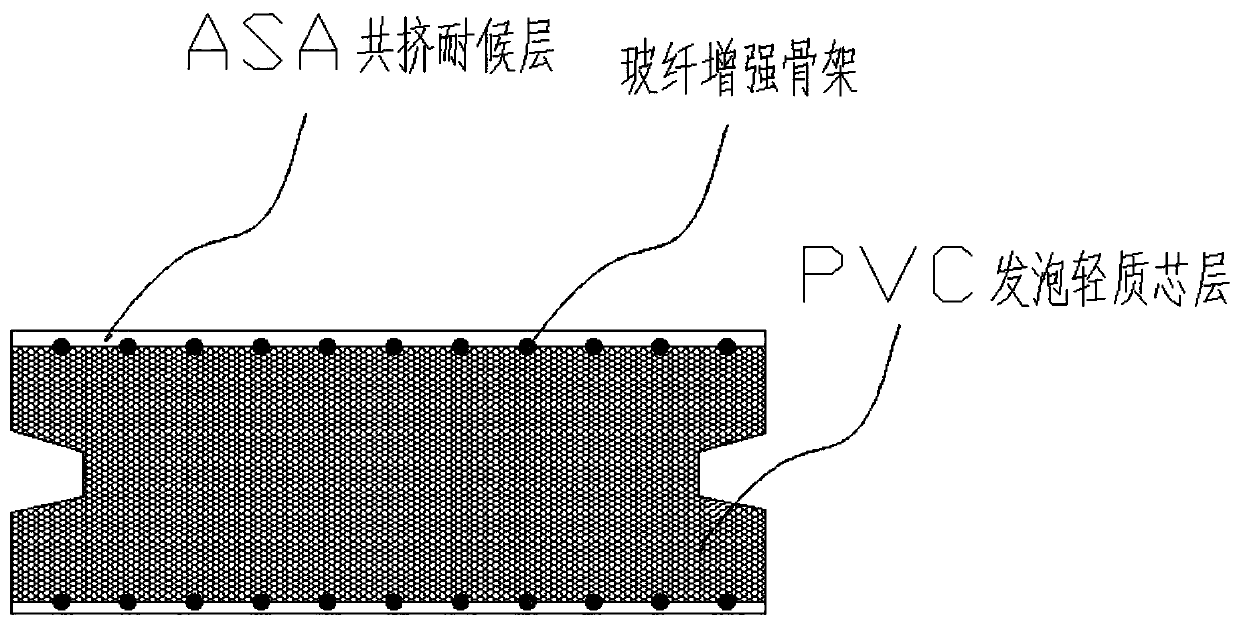

PVC foaming co-extrusion ASA glass fiber reinforcement technology

A process and glass fiber technology, applied in the field of PVC foam sheet extrusion, can solve the problems of easy shrinkage deformation, poor strength of PVC foam sheet, etc., and achieve the effects of good external dimensions, good weather resistance and stable products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Ingredients: according to the formula ingredients, the formula is composed of the following raw materials in parts by weight:

[0046]

[0047]

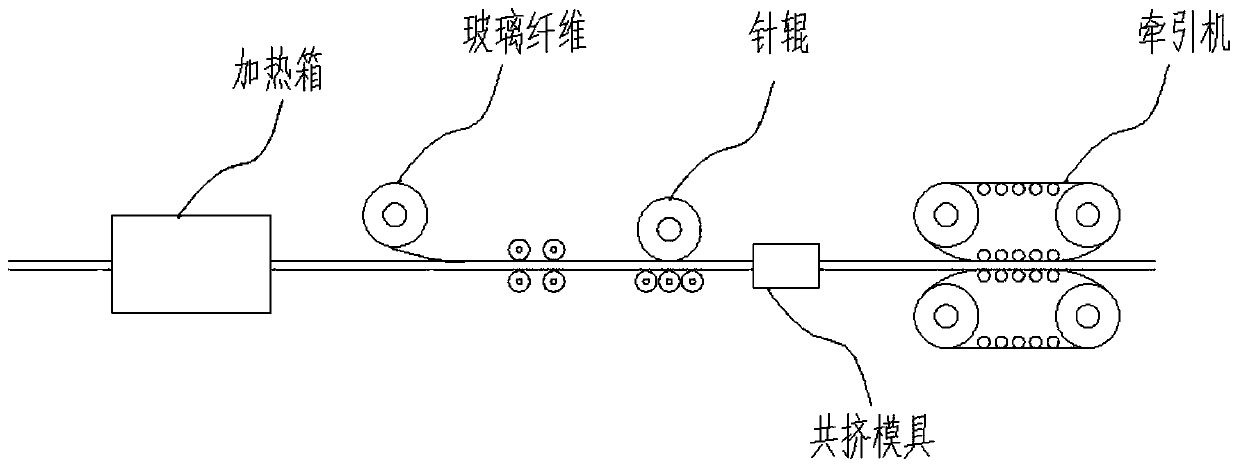

[0048] (2) Extrusion: Send the ingredients in step (1) into the extruder to extrude the whole body foaming base material; Zone 175°C, head heating 165°C, lip die temperature 170°C, die temperature 170°C, extruder screw speed controlled at 22r / min;

[0049] (3) cooling molding: the foamed base material obtained in step (2) is set to cool and form by being arranged on a cooling shaping die at 10 mm from the die;

[0050] (4) traction: the base material obtained in step (3) is drawn out with a tractor, the traction speed of the tractor is synchronous with the extruded profile, and the return speed of the tractor is 10m / min;

[0051] (5) Heating: Send the substrate obtained in step (4) into a heating box for heating, and the heating temperature is 90°C;

[0052] (6) Needle roller treatment: the substrate obtained in st...

Embodiment 2

[0056] (1) Ingredients: according to the formula ingredients, the formula is composed of the following raw materials in parts by weight:

[0057]

[0058]

[0059] (2) Extrusion: Send the ingredients in step (1) into the extruder to extrude the whole body foaming base material; Zone 185°C, head heating 175°C, lip die temperature 185°C, die temperature 185°C, extruder screw speed controlled at 32r / min;

[0060] (3) cooling forming: the foamed base material obtained in step (2) is set to cool and form by being arranged on a cooling shaping die at 200 mm from the die;

[0061] (4) traction: the base material obtained in step (3) is drawn out with a tractor, the traction speed of the tractor is synchronous with the extruded profile, and the return speed of the tractor is 40m / min;

[0062] (5) Heating: Send the base material obtained in step (4) into a heating box for heating, and the heating temperature is 100° C.;

[0063] (6) Needle roller treatment: the substrate obtain...

Embodiment 3

[0067] (1) Ingredients: according to the formula ingredients, the formula is composed of the following raw materials in parts by weight:

[0068]

[0069] (2) Extrusion: Send the ingredients in step (1) into the extruder to extrude the whole body foaming base material; Zone 180°C, head heating 170°C, lip die temperature 180°C, die temperature 175°C, extruder screw speed controlled at 26r / min;

[0070] (3) cooling forming: the foamed base material obtained in step (2) is set to cool and form by being arranged on a cooling shaping die at 100 mm from the die;

[0071] (4) traction: the base material obtained in step (3) is drawn out with a tractor, the traction speed of the tractor is synchronous with the extruded profile, and the return speed of the tractor is 20m / min;

[0072] (5) Heating: Send the base material obtained in step (4) into a heating box for heating, and the heating temperature is 80°C;

[0073] (6) Needle roller treatment: the substrate obtained in step (5) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com