Spinning machine with spindle lifting installation

A spinning frame and spindle technology, which is applied in textiles and papermaking, can solve the problems of slow development of high-speed and large-roll technology, and achieve the effects of convenient and quick maintenance, reduced industrial loss, and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

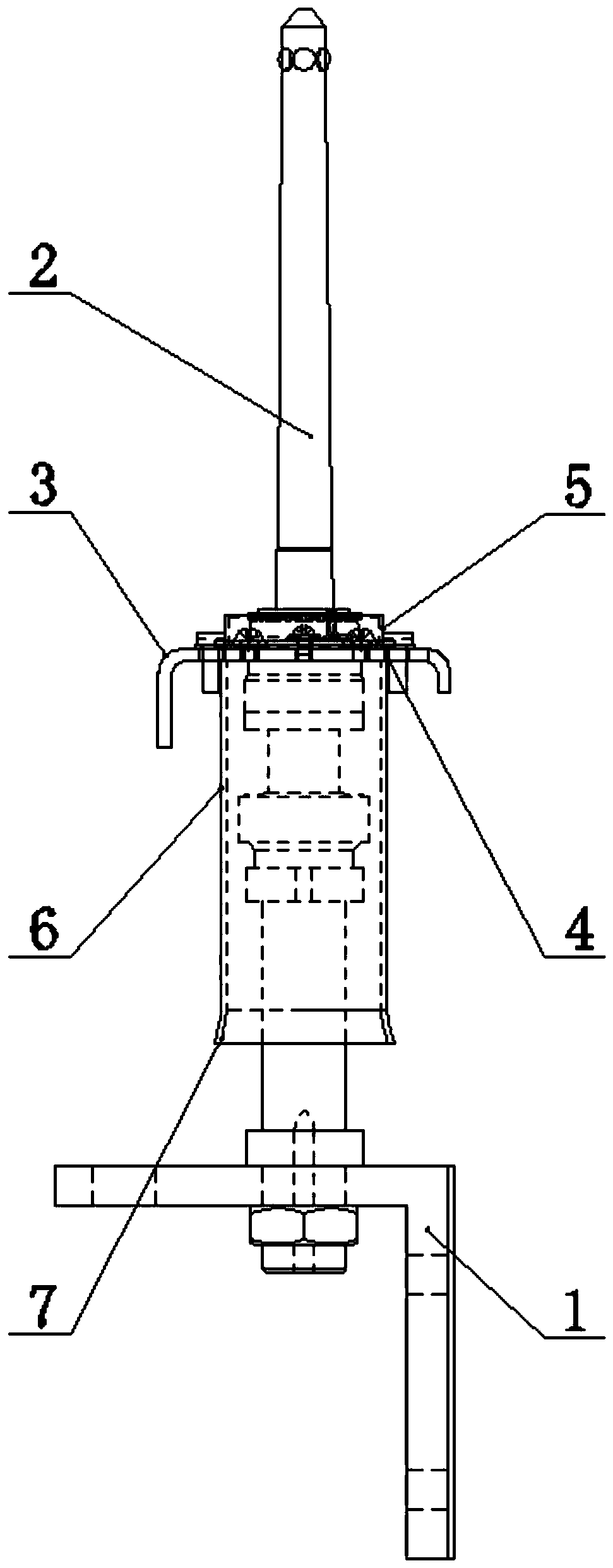

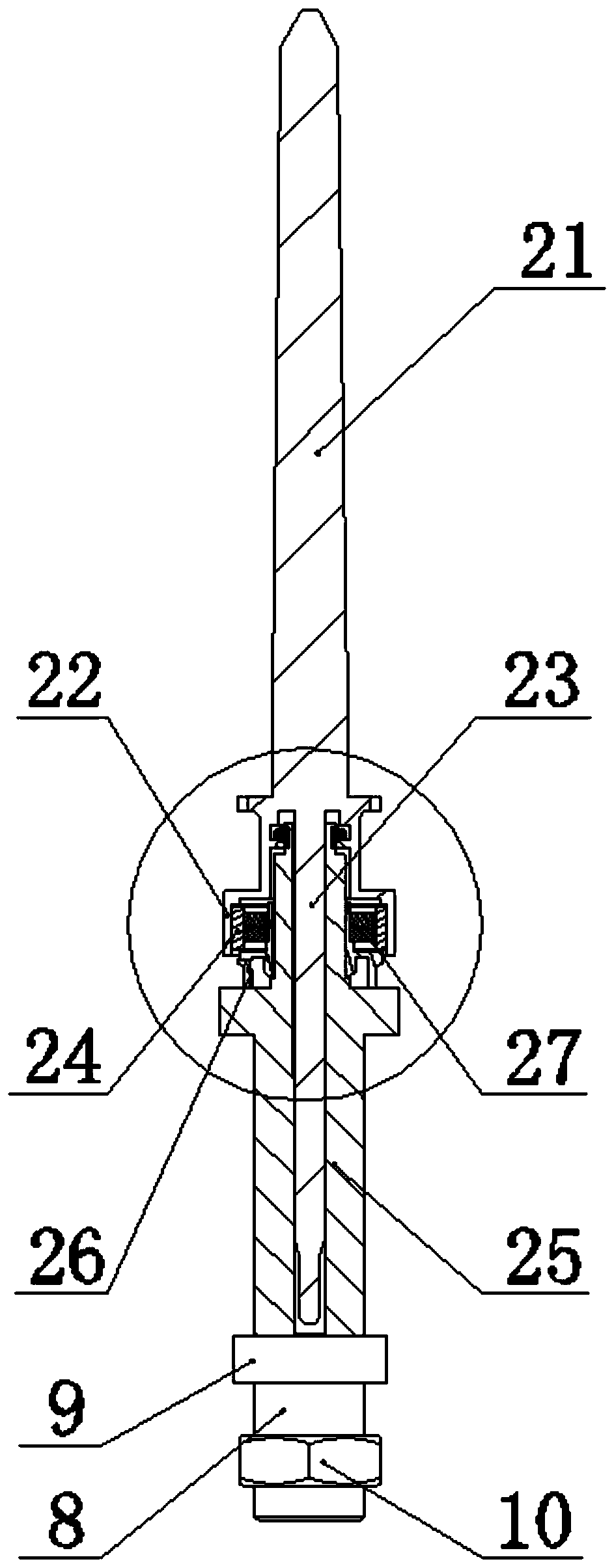

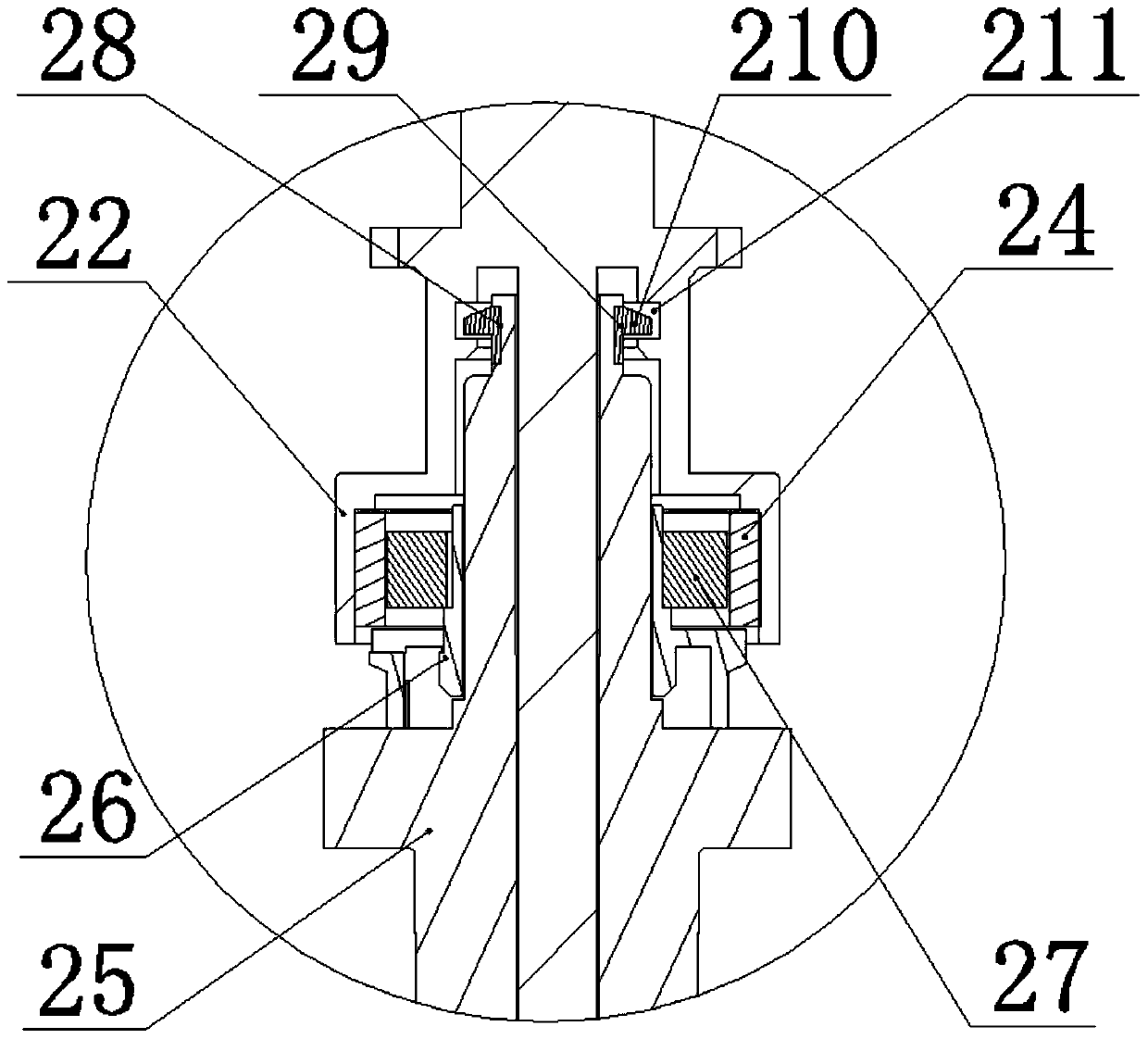

[0047] Such as Figure 1 ~ Figure 3 As shown, a spinning frame in which the spindle is raised and installed in this embodiment includes a dragon tendon 1, a row of spindles 2 is arranged on the dragon tendon 1, and a ring plate 3 is arranged above the dragon tendon 1. The ring plate 3 is provided with a row of through holes 4, the spindles 2 correspond to the through holes 4 one by one, the spindles 2 are mounted in the through holes 4, and the upper side of the through holes 4 is provided with a ring ring 5 , the lower side of the through hole 4 is provided with an energy-saving sleeve 6;

[0048] The lower end of the energy-saving sleeve 6 is provided with a trumpet-shaped opening 7;

[0049] The energy-saving sleeve 6 is connected with the ring plate 3 by screws;

[0050] The diameter of the energy-saving sleeve 6 is slightly larger than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com