Embedded traffic rail assembly

An embedded, transportation technology, applied in the field of rail transit, can solve the problems of potential safety hazards, affecting the levelness of rails, inconvenient rail height adjustment, etc., to achieve the effect of ensuring levelness, realizing height adjustment, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

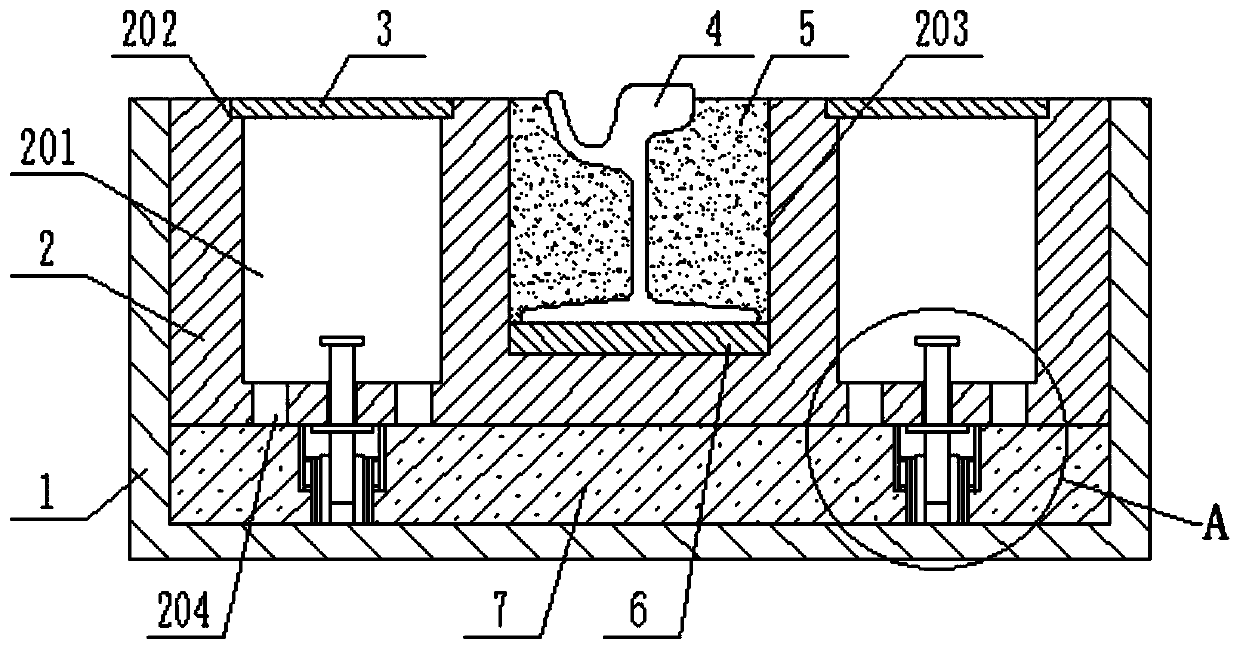

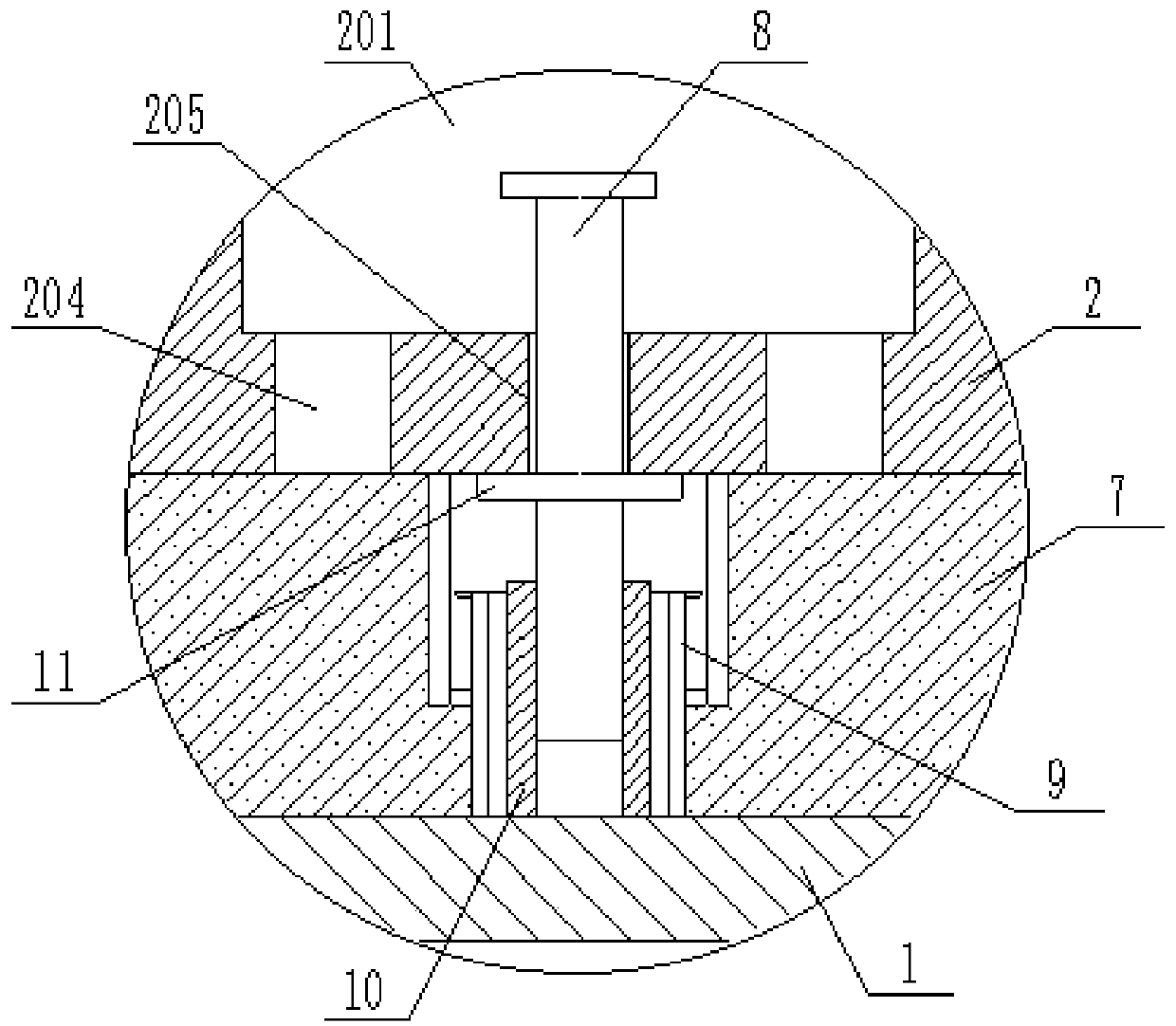

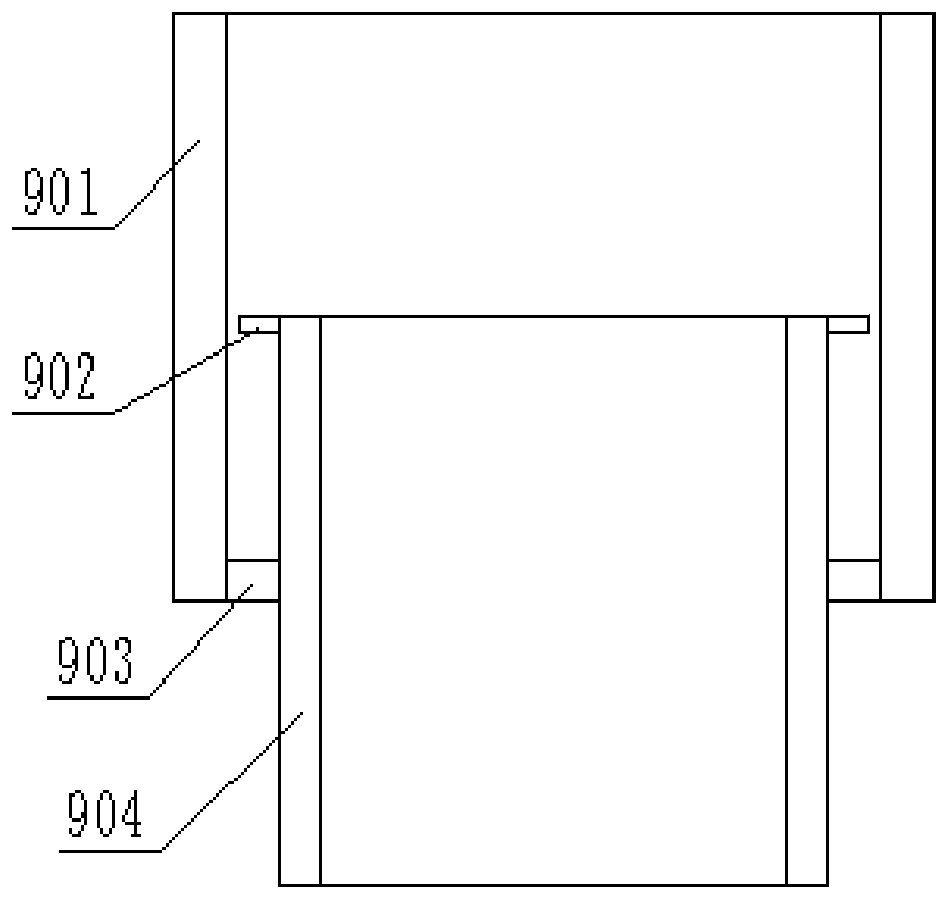

[0035] See Figure 1-Figure 4 As shown, the present invention provides an embedded transportation track assembly, including an external positioning shell 1 and a track plate 2. A placement groove 203 is provided on the surface of the track plate 2 and a shock absorbing pad 6 is provided at the bottom of the placing groove 203. 6 is pasted on the bottom of the placement groove 203 with high-strength structural glue. This arrangement can make the shock absorbing pad 6 fully contact the inner bottom of the placement groove 203. The surface of the shock absorbing pad 6 is provided with a rail 4, which is between the rail 4 and the inner wall of the placement groove 203. Filled with polymer castable 5; four corners of the track plate 2 are provided with adjustment cavities 201, the inner bottom surface of the adjustment cavity 201 is provided with through holes 205 and pouring holes 204, the through holes 205 are provided with adjusting bolts 8 and adjusting bolts 8 An adjusting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com