Rapidly mounted rectangular steel frame support of cast-in-place shear wall of fabricated building

A prefabricated shear wall technology, which is applied in the on-site preparation of building components, construction, building construction, etc., can solve the problems of walls, beams, and slabs that cannot be installed at the same time, scaffolding instability, and large consumption of steel pipes. The overall stability is good, the installation is flexible, and the effect of saving steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

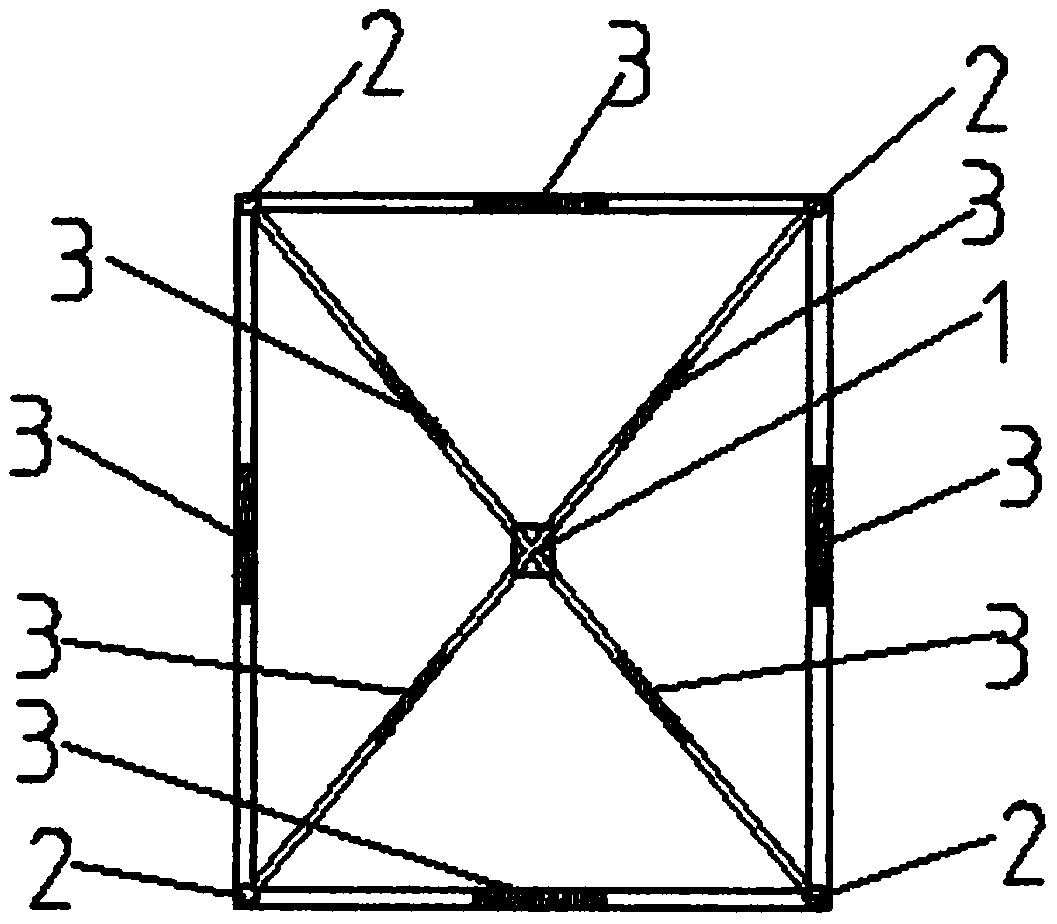

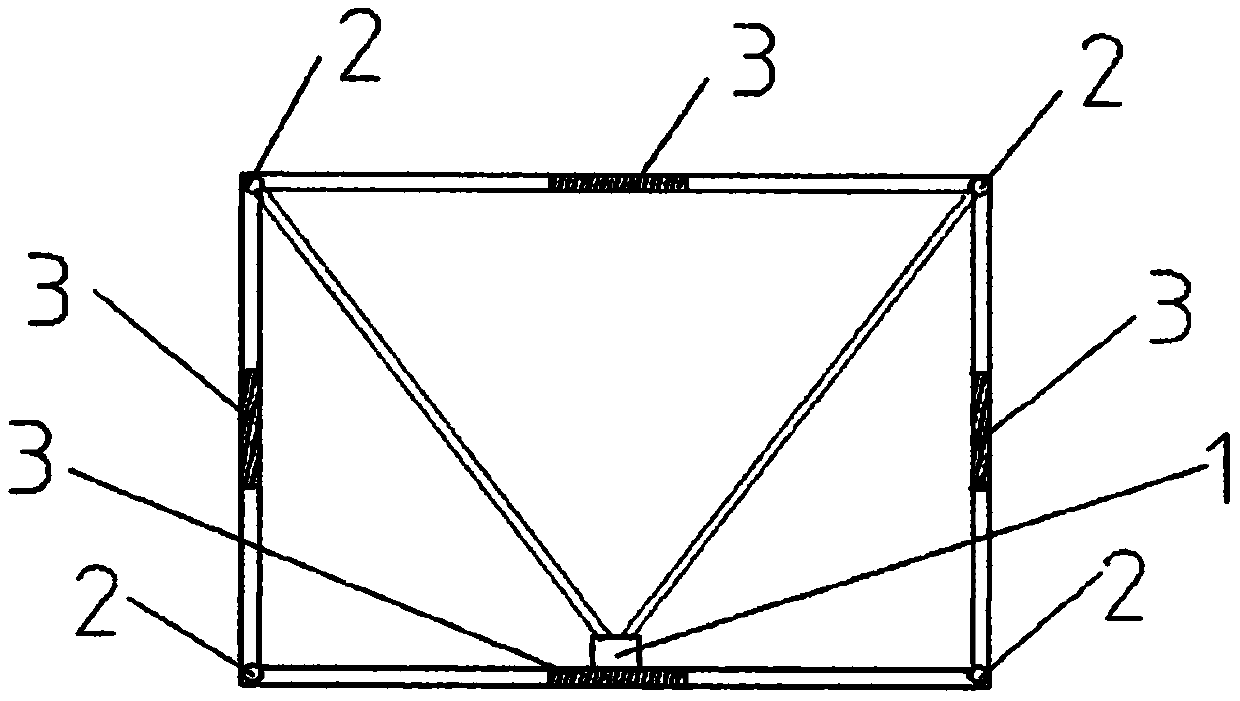

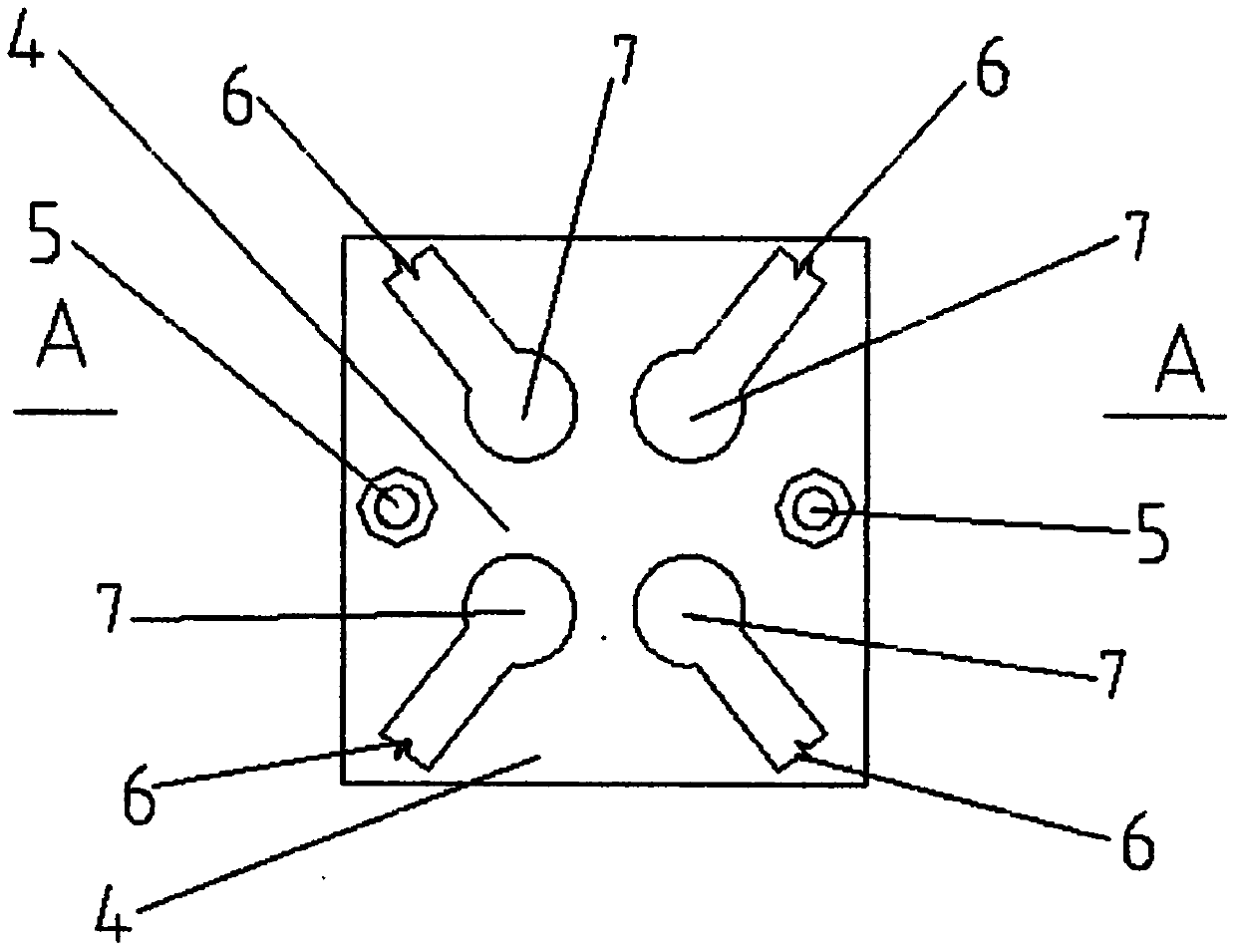

[0031] When assembling rectangular steel brackets with rooms of different sizes on the construction site, adjust the angle of the single connector of the multi-angle connection assembly fixed at the center of the bottom surface of the rectangular steel frame on the floor that has been constructed, and adjust the angles of the four corners connecting the upper part of the rectangular steel bracket. For the angle between the supports, adjust the length of the angle steel side with the expansion joint in the middle to make the corresponding steel bracket. The rapid adjustment of the length of the expansion joint is realized by adjusting the hydraulic oil volume of the expansion joint with the electromechanical and electro-hydraulic machine. The telescopic joint of the rectangular steel frame is adjusted electromechanically, and the gear is rotated by a small hand-held motor to complete the reversing and speed regulation of the gear, so as to realize the rapid adjustment of the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com