Water storage type water heater

A technology of water heater and water storage type, which is applied in fluid heaters, lighting and heating equipment, etc., which can solve the problems of single shell shape, low production efficiency, complicated shell process, etc., and achieve simple forming process, high production efficiency, and rich shapes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

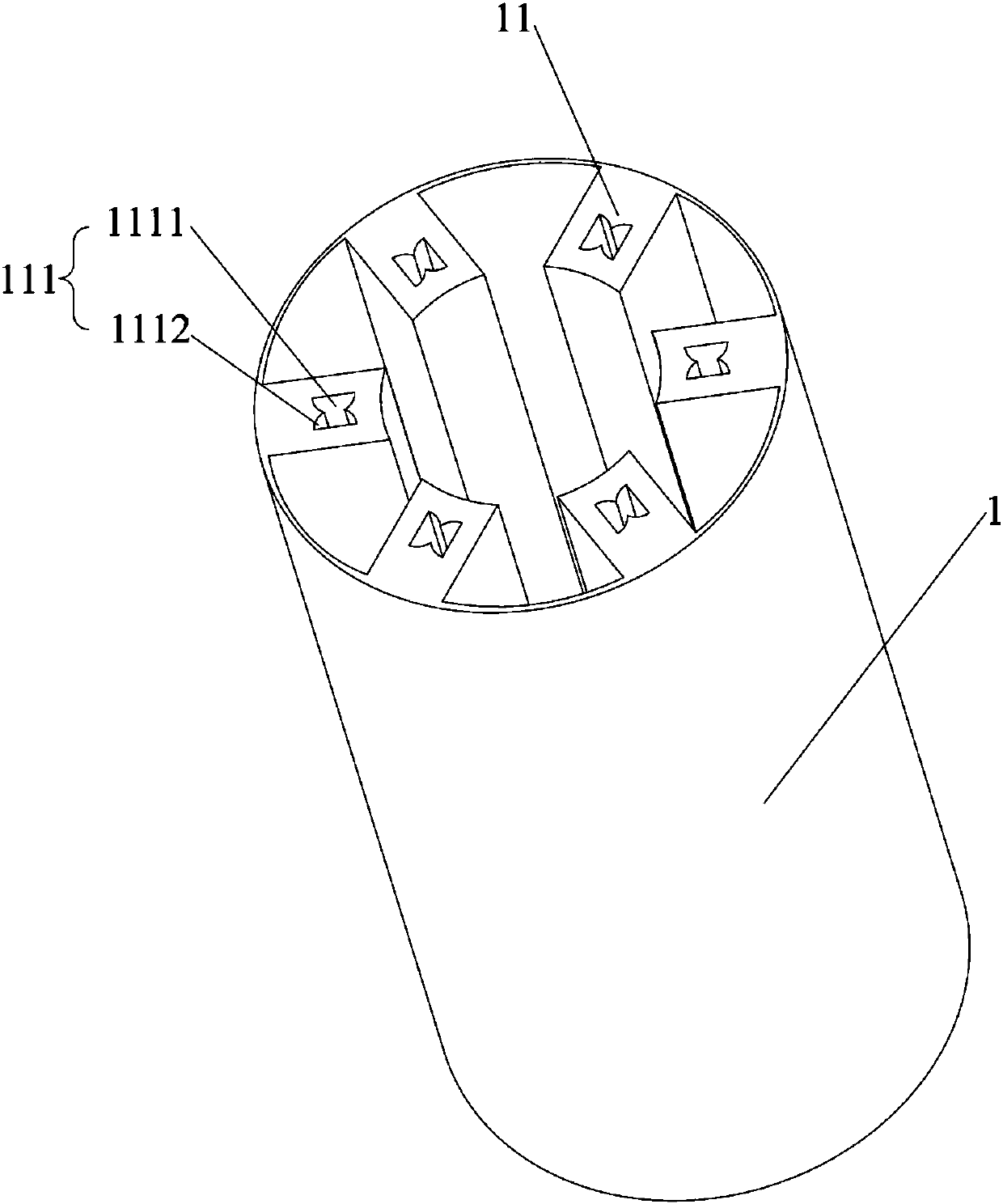

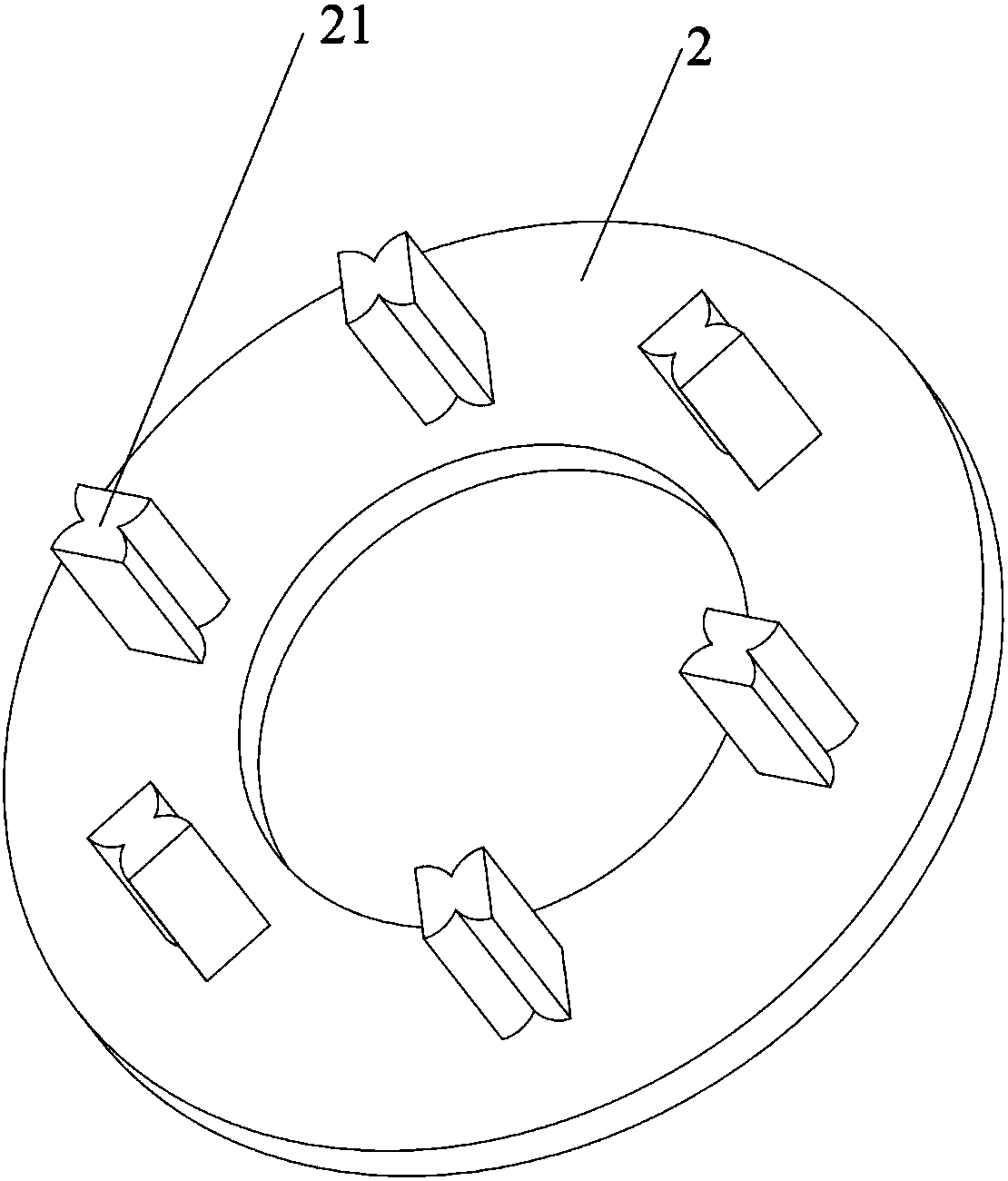

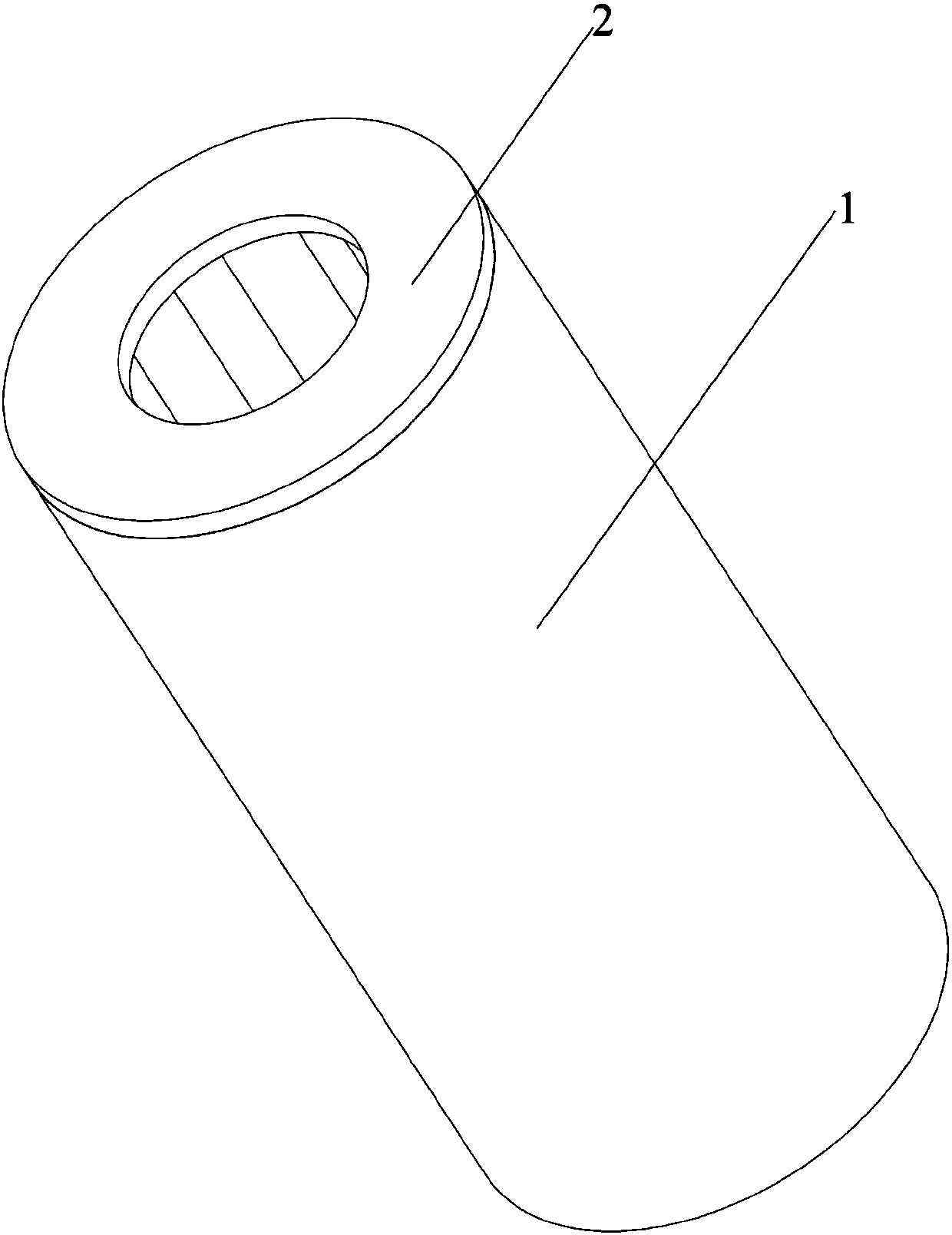

[0027] This embodiment provides a water storage type water heater, such as figure 1 As shown, it includes an outer shell, an inner tank (not shown in the figure) and an insulating layer (not shown in the figure). The outer shell includes a straight section, and the straight section is an extruded integral cylinder 1 . In this embodiment, the casing 1 of the water heater is manufactured by extrusion molding, which makes the manufacturing process of the casing of the water heater simple, improves production efficiency, and avoids the need for the casing 1 in the prior art. The molding process is carried out, which makes it difficult to control the quality of the cylinder body 1 of the shell...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap