A high-temperature cooler with a circular cross-section shell structure and its design method

A technology with a shell structure and a circular cross section, which is applied in the direction of heat exchanger shells, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of shortening the running time of the auxiliary system of the shell cooling medium, insufficient strength and rigidity, etc., to achieve High-efficiency heat exchange, low-cost operation, strong versatility, and the effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

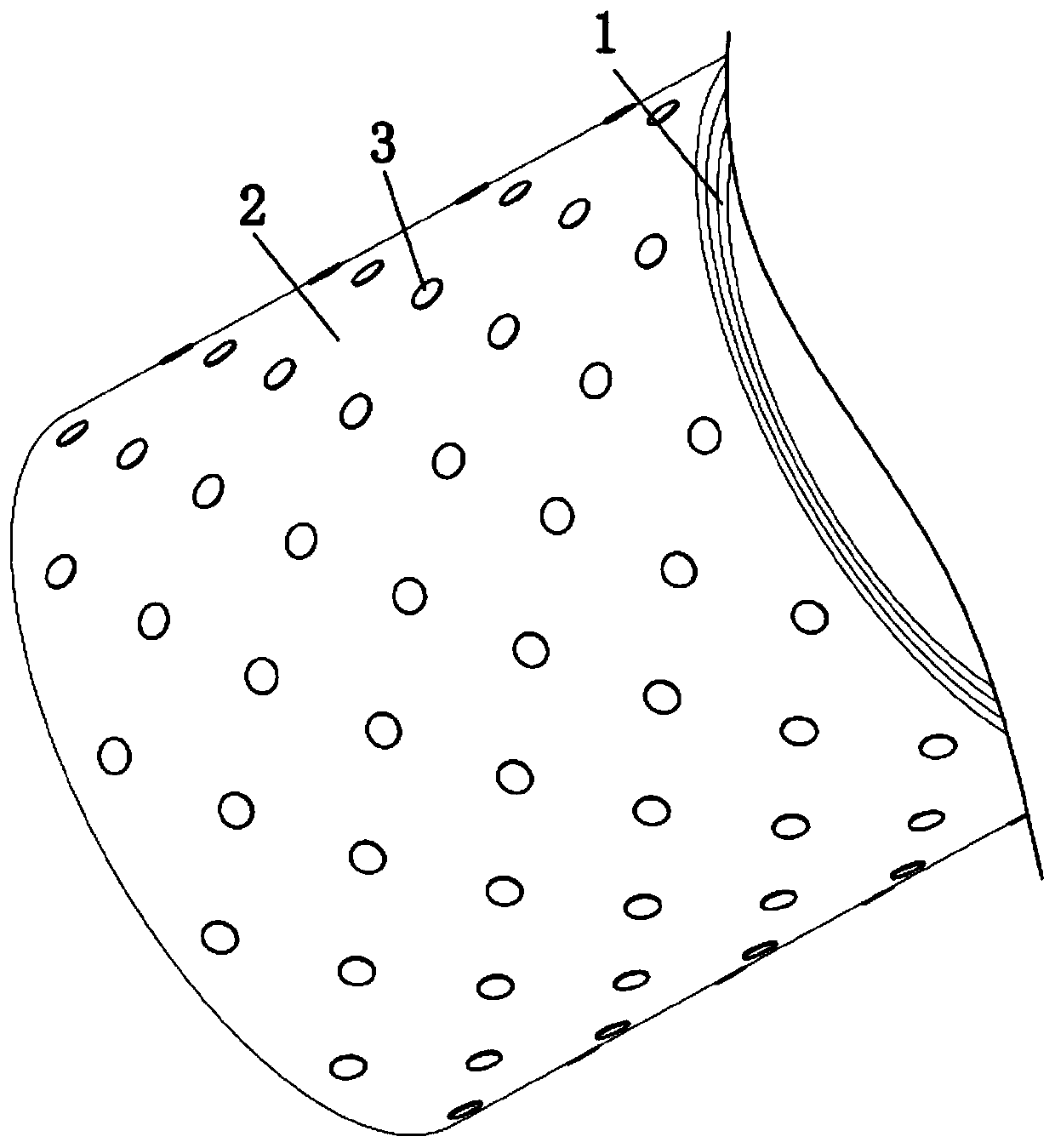

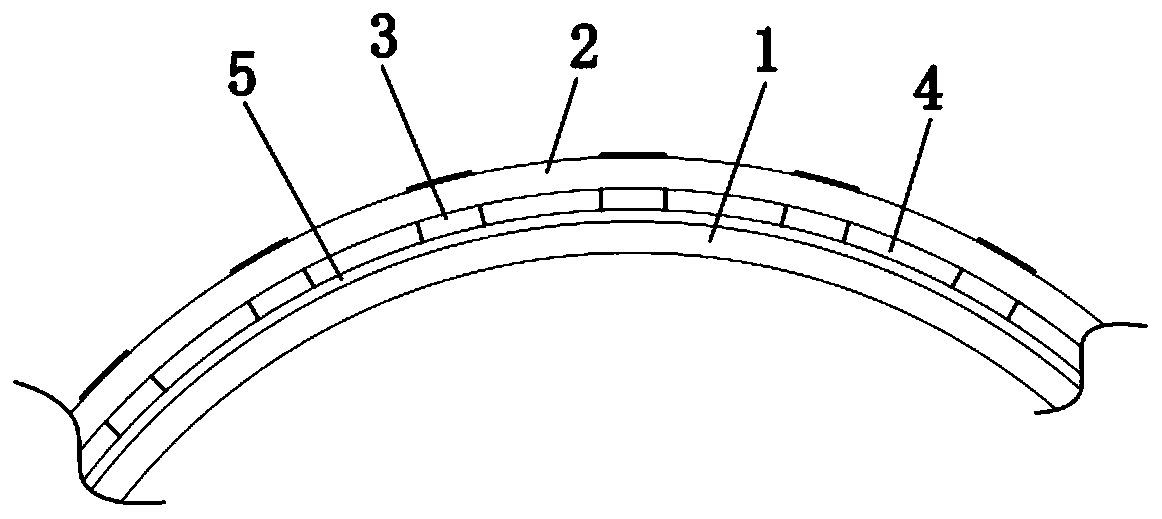

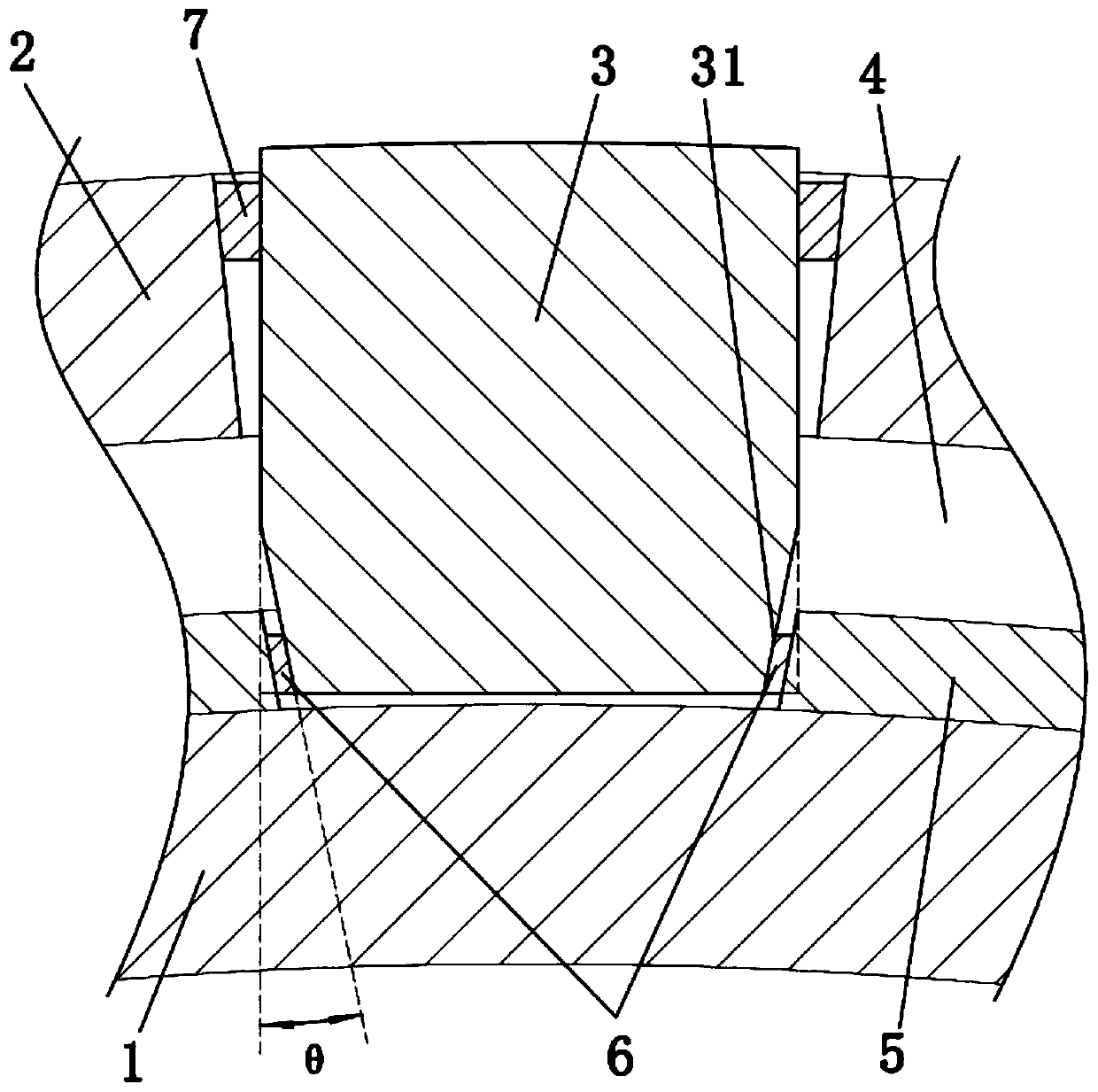

[0049] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides a high-temperature cooler circular cross-section shell structure and its design method. The high-temperature cooler circular cross-section shell structure includes a shell inner cylinder 1, a shell outer cylinder 2, a plug welding reinforcement Body 3 and shell cooling medium 4; the inside of the shell inner cylinder 1 is in contact with the hot fluid, and the outside is in contact with the shell cooling medium 4; the inside of the shell outer cylinder 2 is in contact with the shell cooling medium 4, and the outside is in contact with the external environment ; The housing inner cylinder 1 and the housing outer cylinder 2 are connected as a whole through the plug welding reinforcing body 3, which improves the overall strength and rigidity of the housing.

[0050] The inner side of the casing inner cylinder 1 bears the pressure from the hot fluid, and the outer casing inner cylinde...

Embodiment 2

[0061] Another technical solution of the present application is a method for designing a circular cross-section shell structure of a high-temperature cooler, and the design method includes the following steps:

[0062] Select the material of the shell according to the stress of the shell structure in the working environment and the maximum temperature parameter that may be reached inside the shell inner cylinder;

[0063] According to the stress of the shell structure and considering the heat of the shell material, it is preliminarily determined that the shell structure adopts the structure type of interlayer water cooling and the wall thickness of the shell inner cylinder and the shell outer cylinder. Through heat transfer calculation, it is determined that the shell structure maintains the allowable Cooling water consumption and cooling effect at temperature;

[0064] According to the strength and stiffness analysis results of the initially determined shell structure, the ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com