Leakage testing and running-in testing method of fuel cell

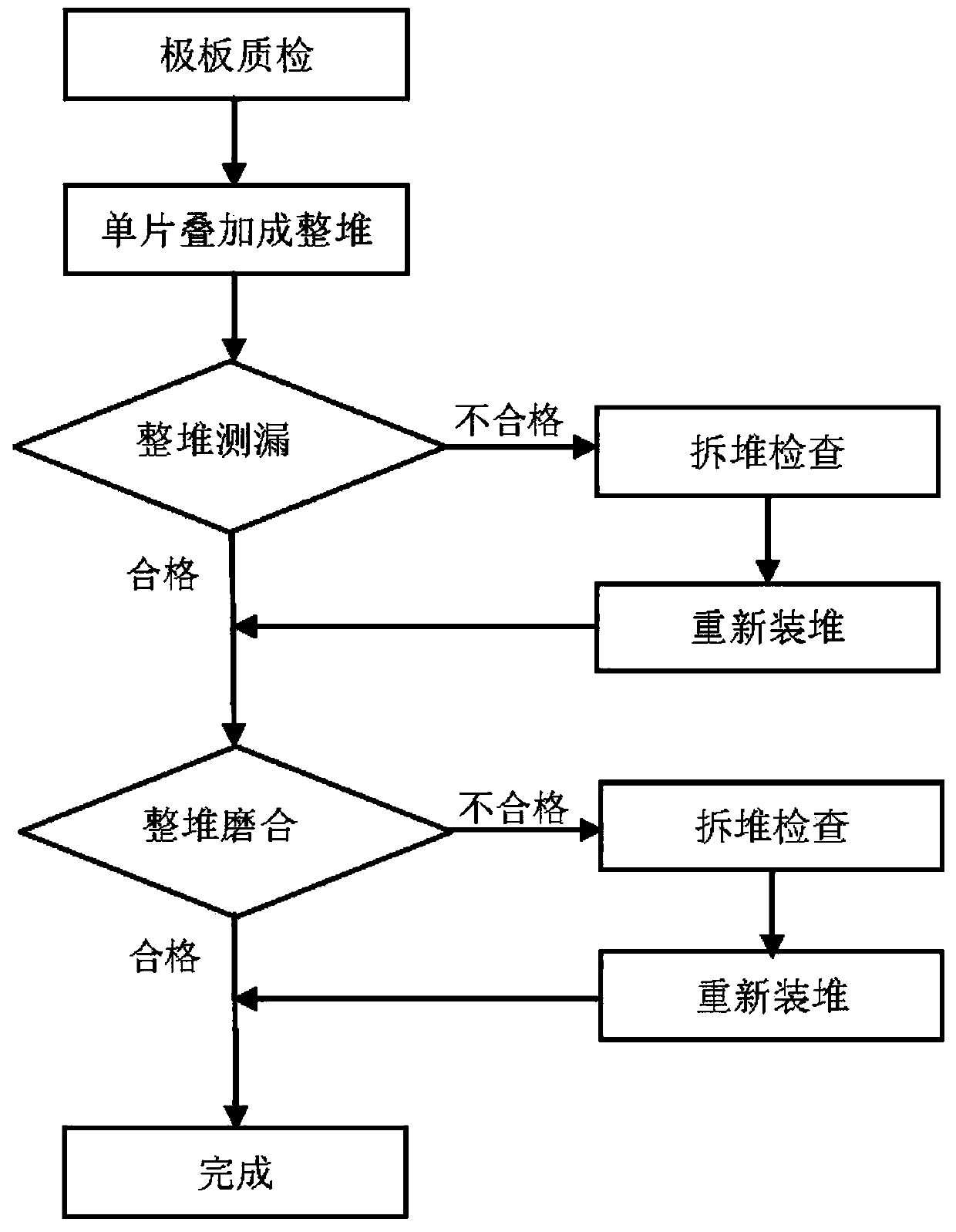

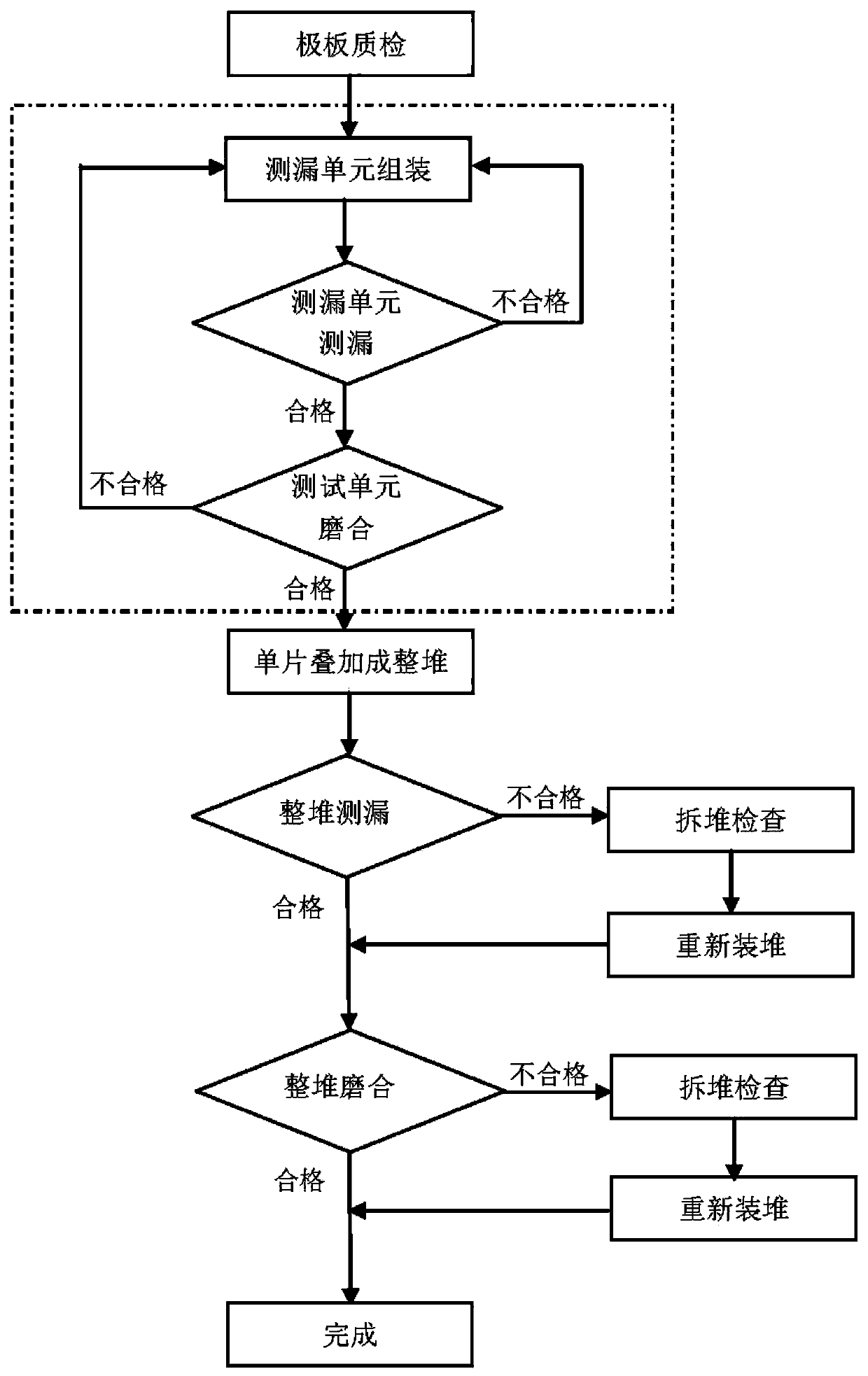

A test method and fuel cell technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of incomplete air tightness of the stack, time-consuming disassembly and assembly of the stack, damage to multiple membrane electrodes, etc. , to achieve the effect of improving the one-time qualified rate, improving the assembly efficiency and success rate, and quickly and quickly leak testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

[0030] refer to figure 2 , the fuel cell leak detection and running-in test method of the present invention, after the fuel cell boards pass the quality inspection and before being stacked into a whole pile, the leak detection and running-in test are carried out by the following method:

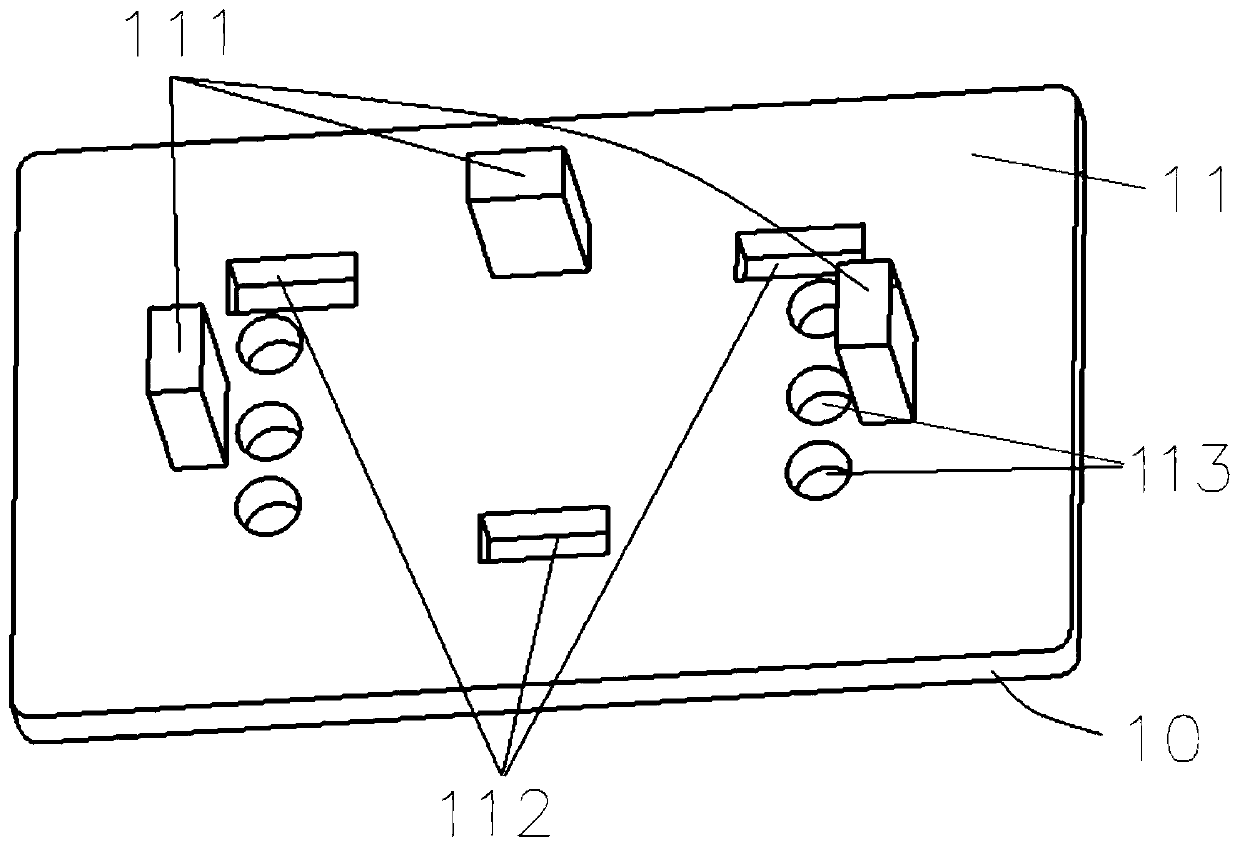

[0031] S1: Stack several membrane electrodes and bipolar plates 51 on the stacking jig 10 to form a leak detection unit 50, such as Figure 4 As shown, the bottom of the leak detection unit 50 is the cathode tail plate assembly 52, the top is the anode tail plate assembly 53, the middle is the membrane electrode and the bipolar plate 51, and the number of the membrane electrode and the bipolar plate 51 is 5-10 Group, the number of fuel cells is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com