Method for extracting rolling bearing fault feature based on EEMD and K-GDE

A rolling bearing and fault feature technology, which is applied in the field of rolling bearing fault feature extraction, can solve problems such as misjudgment or even wrong diagnosis, low efficiency, cumbersome diagnostic calculation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

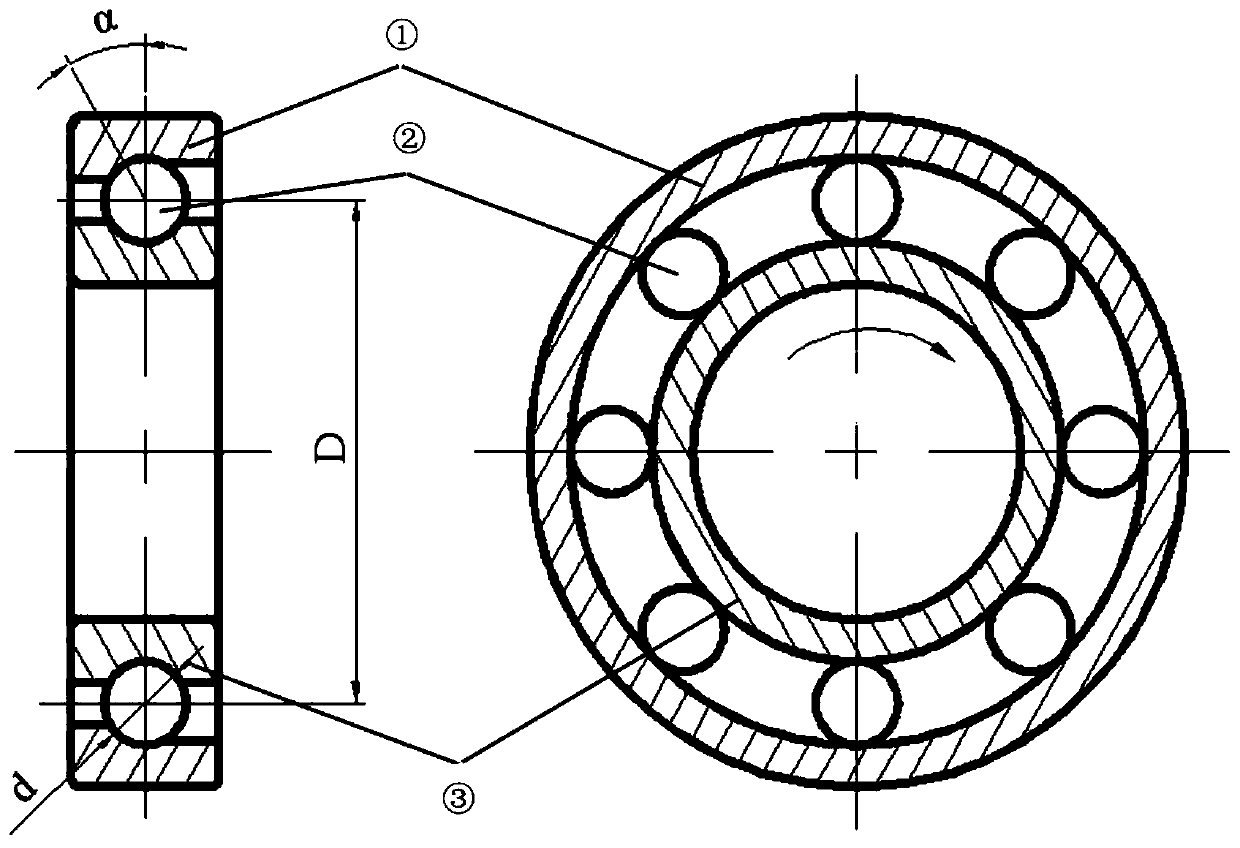

[0062] The model used in the experiment is GB6220 deep groove ball rolling bearing, the bearing diagram is as follows figure 1 As shown, it is composed of outer ring ①, ball ② and inner ring ③; the detailed parameters of rolling bearings are shown in Table 1.

[0063] Table 1 Basic parameters of rolling bearing GB6220

[0064]

[0065] In order to simulate the local failure of each component in the rolling bearing, a pit with a diameter of 2 mm and a depth of 1 mm is machined on the outer ring of the bearing, and the processing method is EDM. In the experiment, the motor speed is set to 444r / min, the load applied to the rolling bearing is 15.68kN through the amplification of the force of the loading mechanism, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com