System and method for detecting sulfur content of automotive diesel oil

A sulfur content detection vehicle technology, applied in the detection system of vehicle diesel sulfur content, using PM sensor to detect vehicle diesel sulfur content, can solve the problem of inaccurate measurement of diesel sulfur content, achieve high accuracy and simple calculation Efficient and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

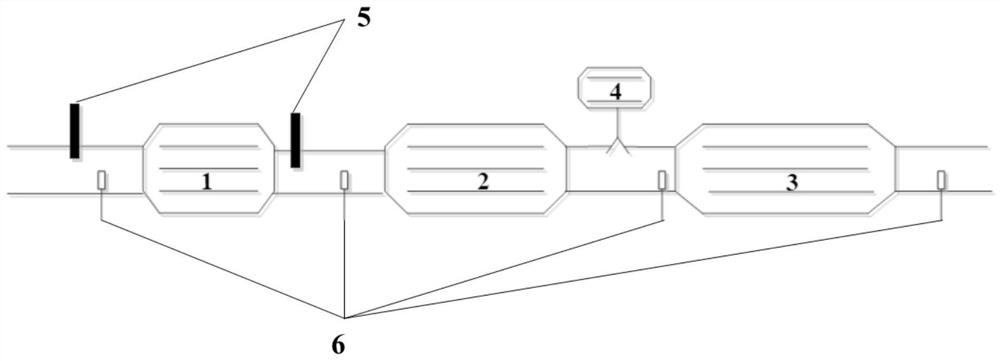

Image

Examples

Embodiment 1

[0062] The present embodiment provides a system and method for detecting the sulfur content of diesel fuel for vehicles, the system is the same as the system described in the specific embodiment, and the method is the same as the method in the specific embodiment section.

Embodiment 2

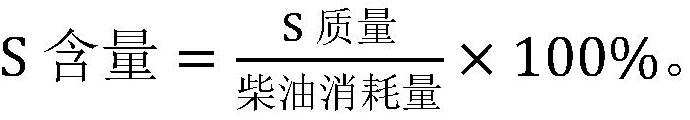

[0064] The present embodiment provides a system and method for detecting the sulfur content of diesel fuel for vehicles. The system is the same as the system described in the specific embodiment, and the method is based on the method in the specific embodiment, and the difference only lies in: step (2) , the sulfate quality also needs to be divided by SO 2 conversion rate, and then calculate the S mass according to the law of conservation of mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com