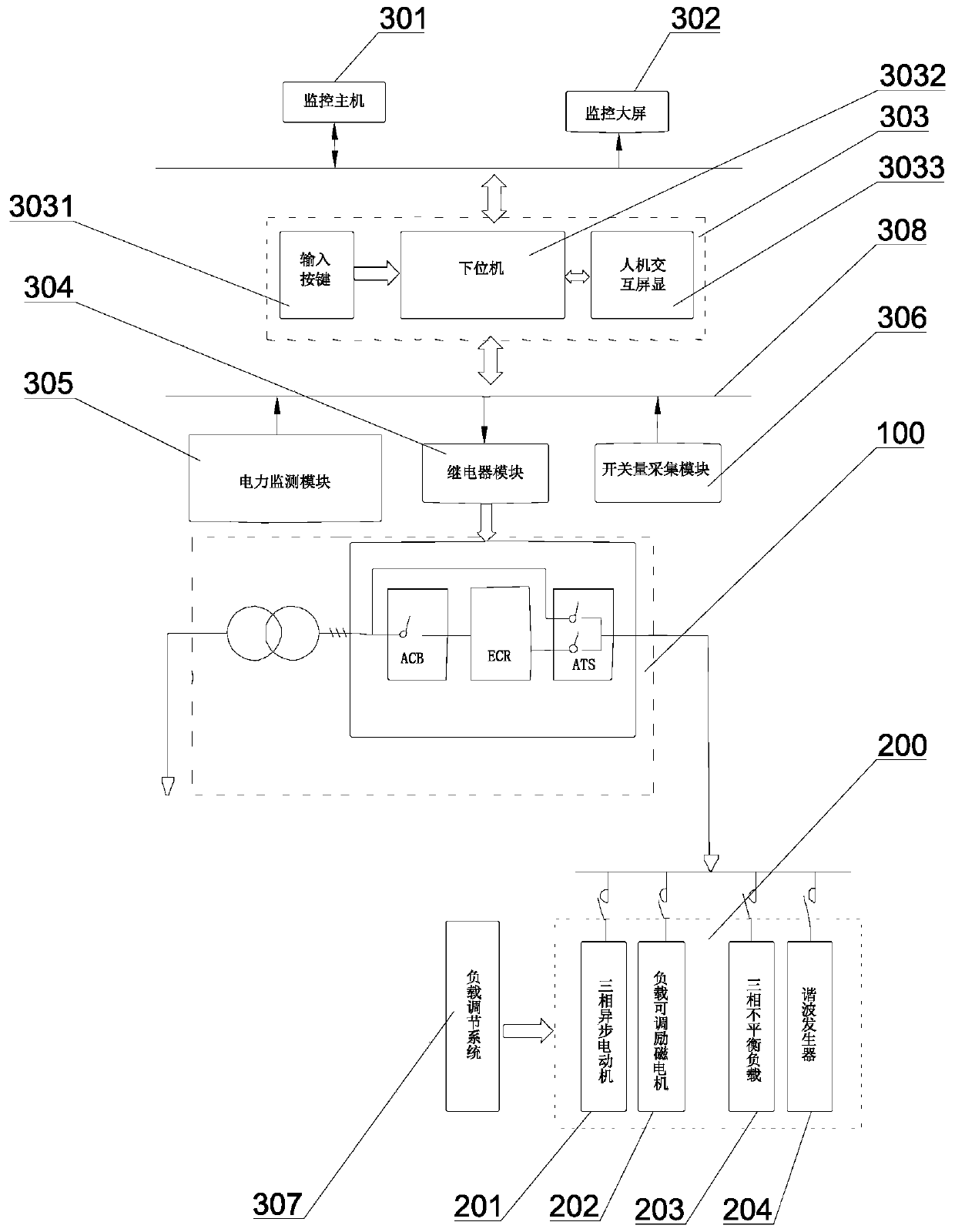

A high-low voltage on-line energy-saving verification system and method

A verification system, high and low voltage technology, applied in the direction of instruments, data processing applications, resources, etc., can solve the problems of hard to distinguish power-saving effect, difficult to evaluate energy-saving governance, and difficult to calculate power-saving rate, so as to ensure stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

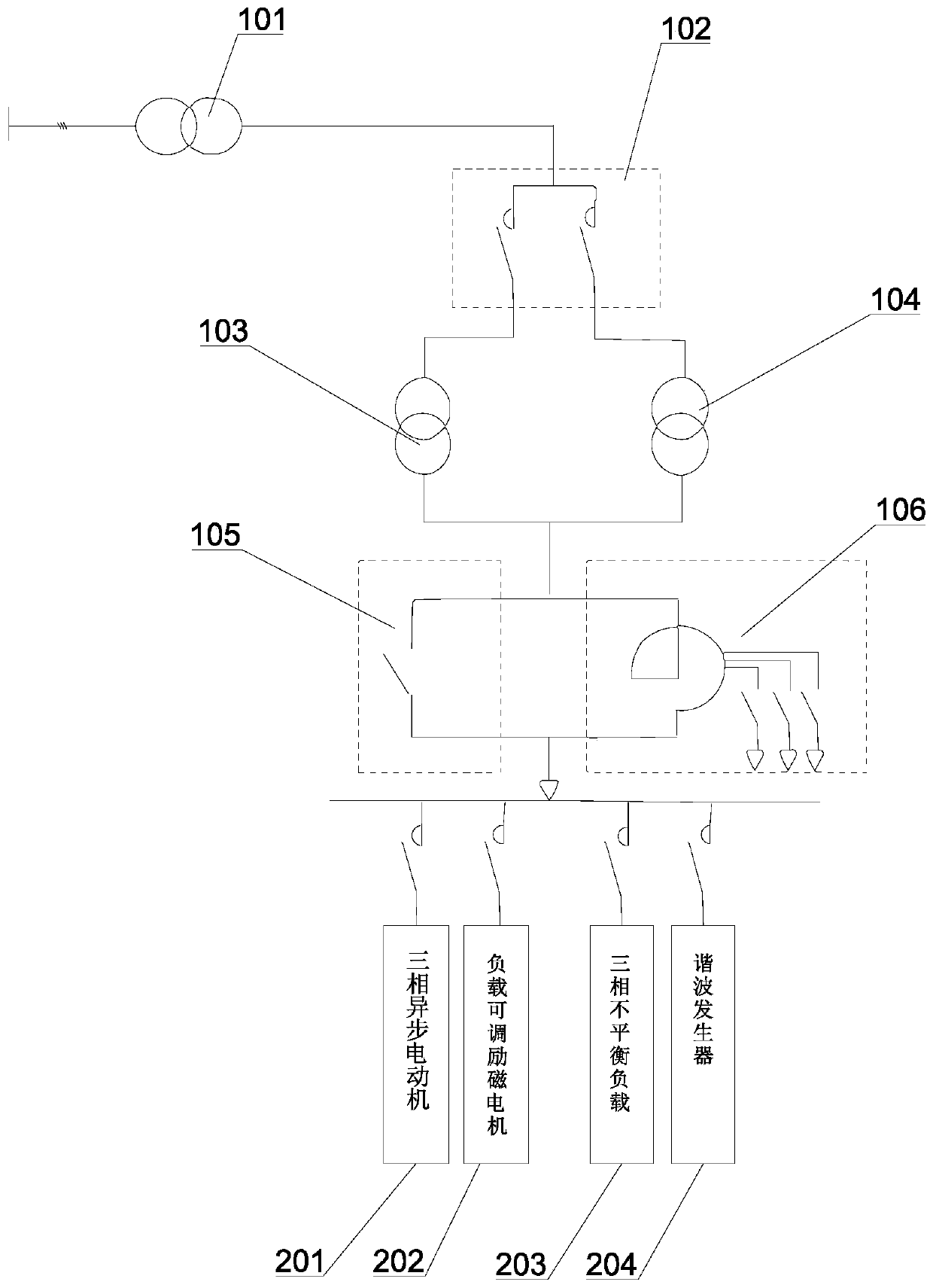

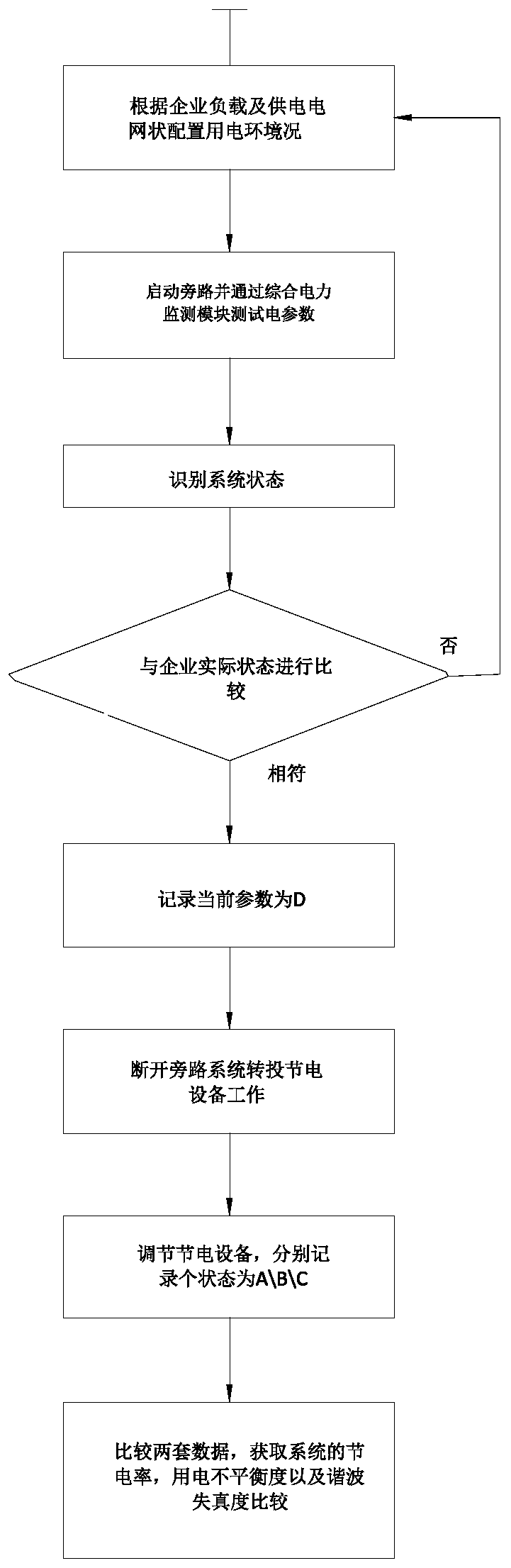

Embodiment 1

[0059] Embodiment 1: For grid fluctuations, by adjusting the line voltage regulator 101, the line voltage of the system is kept constant, such as 400V; the matching of electric loads is kept constant, and the state of resistive load and inductive load remains unchanged. Then, connect the produced power-saving device 106 in series in the main circuit; at this time, manually adjust the gear position of the power-saving device 106, for example, when there are three gears of A, B, and C, the three gears correspond to different voltages respectively working conditions. The active power under the operating conditions of the three gears is recorded respectively, and 3 sets of data are obtained, and these 3 sets of data respectively represent the power consumption of the present invention under the power-saving state. Then switch the operation mode of the power saving device 106 to the "bypass" state, and the bypass switch 105 is closed. At the same time, a set of data is recorded. We...

Embodiment 2

[0060] Example 2: For three-phase unbalance, three-phase unbalance is ubiquitous in industrial power systems, manifested as: unbalance between three-phase voltages, unbalance between three-phase currents, zero-sequence current Existence, etc., and some unbalanced degrees reach more than 20%, which seriously affects the overall efficiency and safety of the system's electric energy.

[0061] First, adjust the voltage of the power system to a stable state, such as 400V. In the power system, rationally allocate the load structure, put in a single-phase load electric heater with 3 kW, and connect a three-phase asynchronous motor with 11 kW. There are several lighting systems; at the same time, the produced power saving device 106 is connected in series in the main circuit, and any gear is kept unchanged; at this time, the power of the single-phase load is manually adjusted, and the operation of the power saving device 106 is recorded by the present invention state, the three-phase ...

Embodiment 3

[0062] Embodiment 3: Harmonic pollution is very harmful to the industrial production system. The present invention can effectively detect the harmonic control of the system, and can evaluate and optimize the harmonic control scheme. The specific steps are: connect the harmonic generating device 204 in parallel to the power consumption system, and observe the change of the harmonic value in the power-saving state and the bypass state by outputting different 2-25th harmonics. By comparison, it is determined whether the performance and quality of the power saving device 106 are good or bad.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com