Cable cooling device

A cooling device and cable technology, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of poor cooling effect and achieve good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In conjunction with the accompanying drawings and specific embodiments, the present invention is further elaborated:

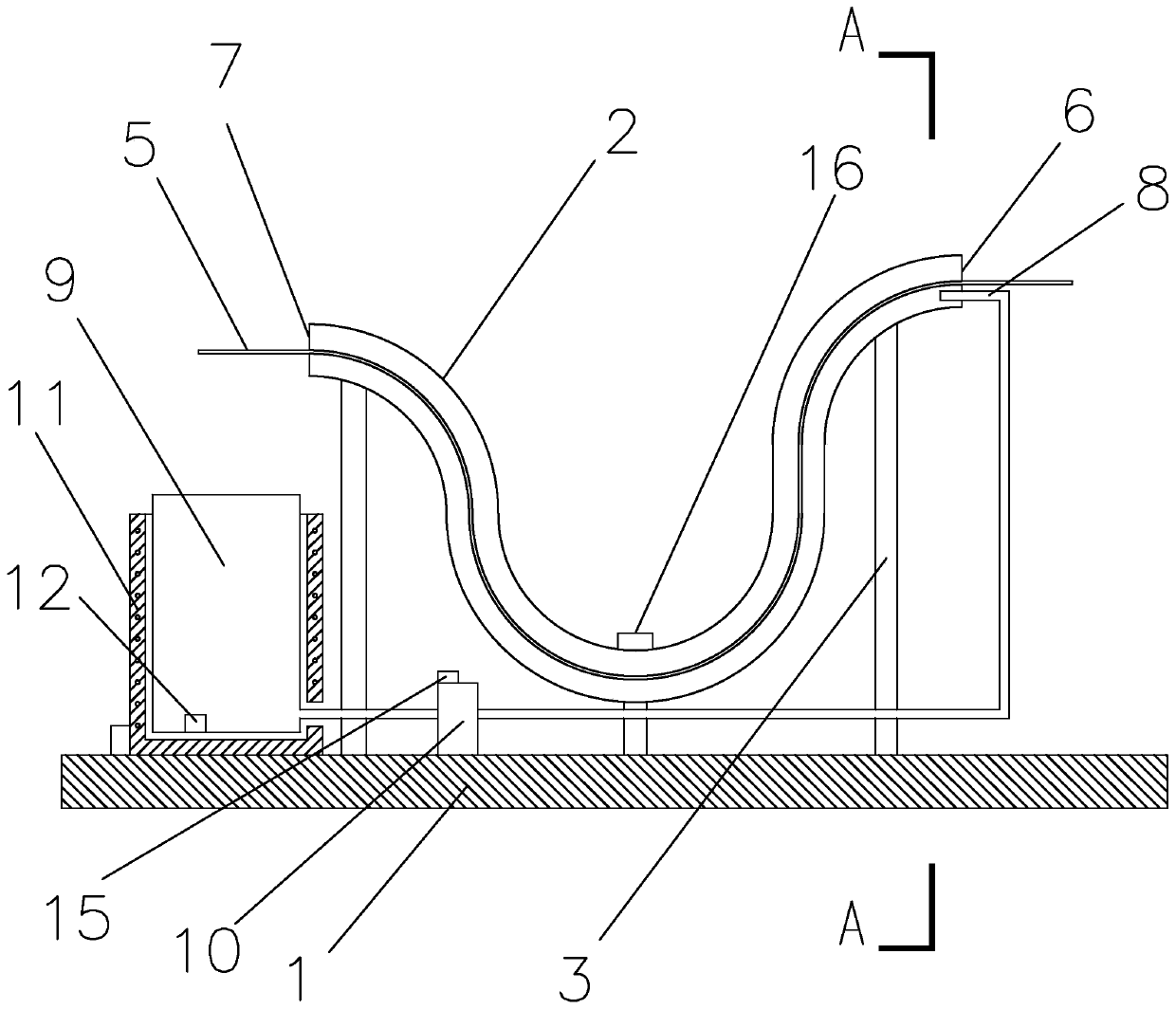

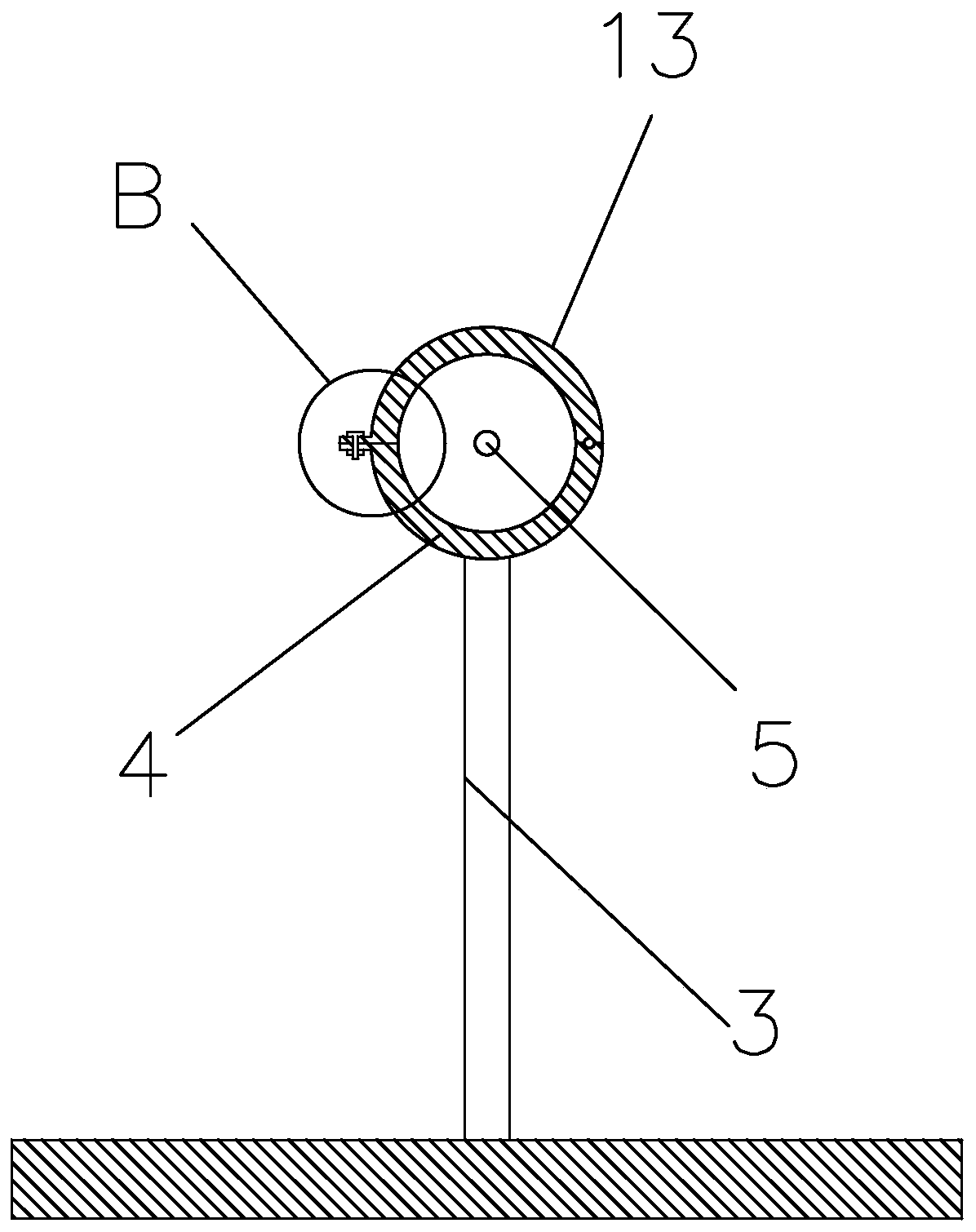

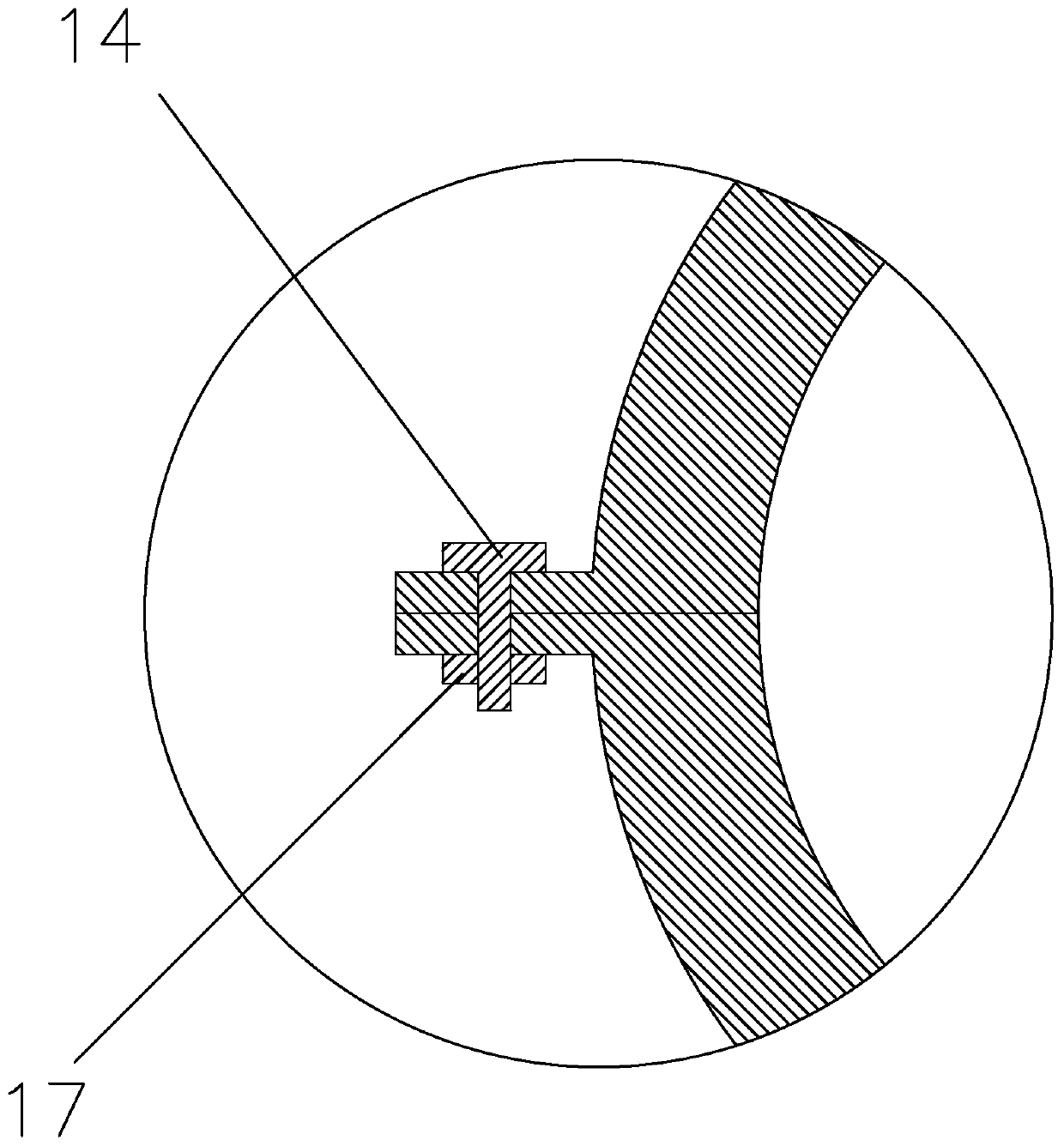

[0021] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 It is a cable cooling device, including a base 1, on which a bellows 2 for cables 5 to pass is arranged, the bellows 2 is bent in a U shape, and one end of the bellows 2 is a cooling water inlet 6. The other end of the bellows 2 is a cooling water outlet 7, and the two ends and the middle of the bellows 2 are provided with pillars 3, and the bases 1 of the pillars 3 are all fixedly connected to the base 1, and the top of the pillars 3 is connected to the The bellows 2 are connected, the level of the cooling water inlet 6 is higher than the level of the cooling water outlet 7, the cooling water inlet 6 is provided with a cooling water pipe 8, and the cooling water outlet 7 is provided with a cooling water recovery tank 9. The cooling water pipe 8 is connected to the coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com