Image sensor, manufacturing method of image sensor, camera module and manufacturing method of camera module

An image sensor and pixel layer technology, applied in the field of structured light, can solve the problems of increasing camera modules, affecting production efficiency, and numerous camera module installation procedures, reducing module thickness, improving production efficiency, and ensuring color imaging quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

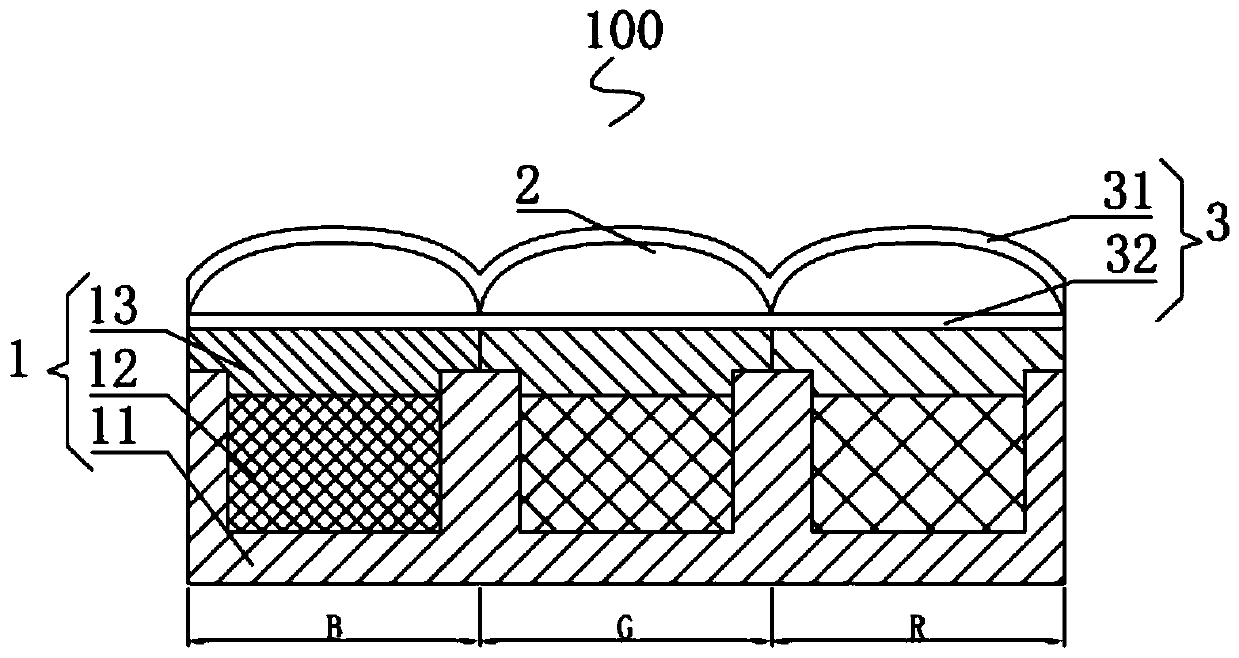

[0031] Such as figure 1 As shown, it represents an image sensor 100 provided by the present invention. The image sensor 100 includes a pixel layer 1 and a microlens layer 2 disposed on the pixel layer 1 ; a filter film 3 is provided on the surface of the microlens layer 2 .

[0032] In this way, since the filter film 3 is directly arranged on the microlens layer 2 of the image sensor 100, such an image sensor 100 can directly realize the filtering function through the filter film 3 when receiving light, so that it can be used in camera modules. In the group, the setting of the optical filter can be omitted, which effectively reduces the thickness of the module, reduces the installation process, and improves production efficiency.

[0033] More specifically, in this embodiment, the filter film 3 includes an infrared filter film 31 and an antireflection film 32 . More specifically, the infrared filter film 31 is arranged on the side of the microlens layer 2 facing the pixel la...

Embodiment 2

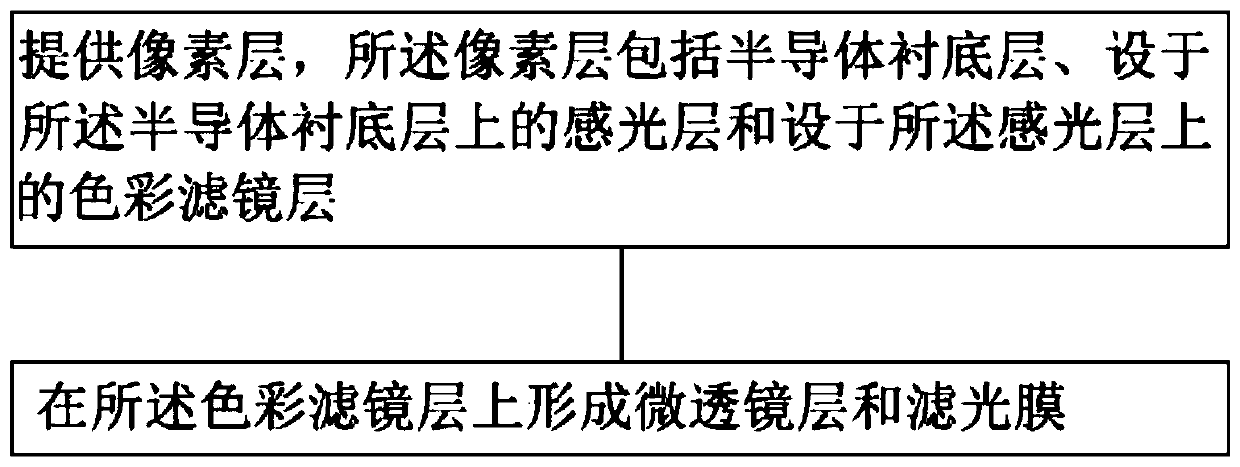

[0036] Such as figure 2 As shown, it shows a manufacturing method of an image sensor provided in this embodiment. The preparation method comprises the following steps:

[0037] Step 1: providing a pixel layer, the pixel layer including a semiconductor substrate layer, a photosensitive layer disposed on the semiconductor substrate layer, and a color filter layer disposed on the photosensitive layer;

[0038] Step 2: forming a microlens layer and a filter film on the color filter layer.

[0039] More specifically, the filter film includes an infrared filter film and an anti-reflection film, and the step 2 includes: step 2.1: forming an anti-reflection film on the color filter layer; step 2.2, forming an anti-reflection film on the anti-reflection film A microlens layer is formed on the microlens layer; specifically, the material of the microlens layer can be organic material or glass; step 2.3: forming an infrared filter film on the microlens layer.

[0040] In this way, by ...

Embodiment 3

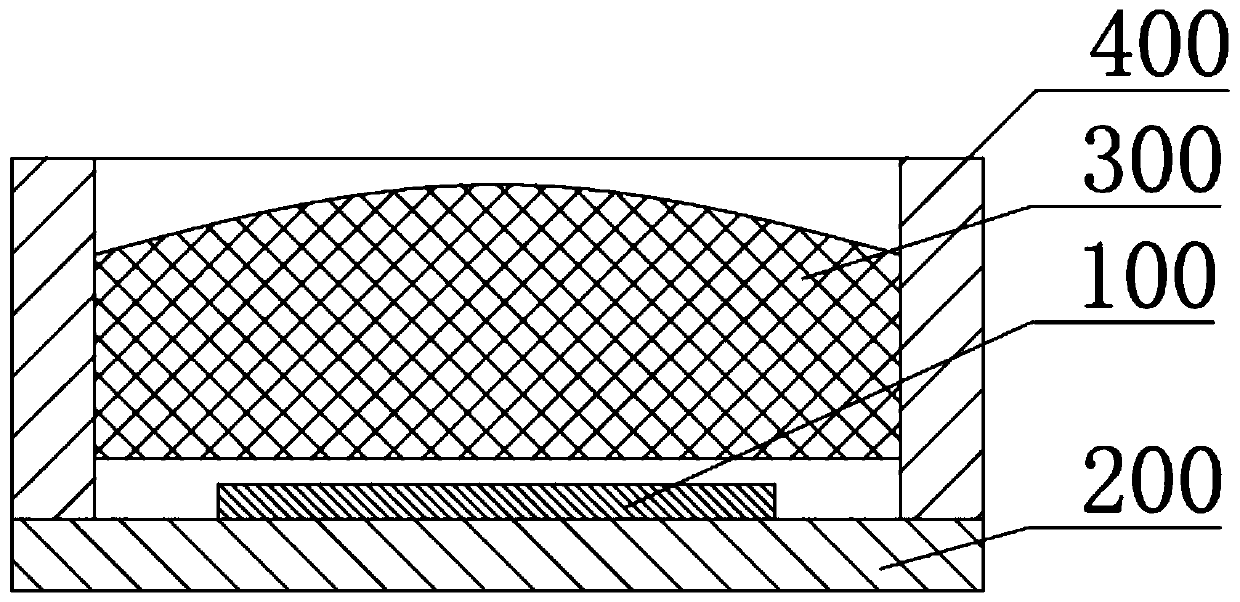

[0042] Such as image 3 As shown, it shows a camera module provided by this embodiment, which includes the image sensor 100 described in the above embodiment, and also includes a circuit board 200 electrically connected to the image sensor 100, and is arranged on the image sensor The lens group 300 on the incident light line 100 and the carrier 400 supporting the lens group 300 .

[0043] In this way, since in this embodiment, the microlens layer of the image sensor 100 is provided with a filter film, so that such an image sensor 100 can directly achieve the filtering effect through the filter film when receiving light. The camera module provided eliminates the need for filter settings, which calmly and effectively reduces the thickness of the camera module, reduces the installation process, and improves production efficiency.

[0044] Moreover, since the arrangement of the optical filter is omitted, the arrangement of the base for supporting the optical filter can also be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com