Electric wire stripping combined device of cable insulating layer

A technology of cable insulation and combination device, applied in the direction of dismantling/armoring cable equipment, etc., can solve the problems of easily damaged cable inner core, bulky, complex structure, etc., achieve simple structure, high stripping speed, and prevent the stripping shaft from being separated. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

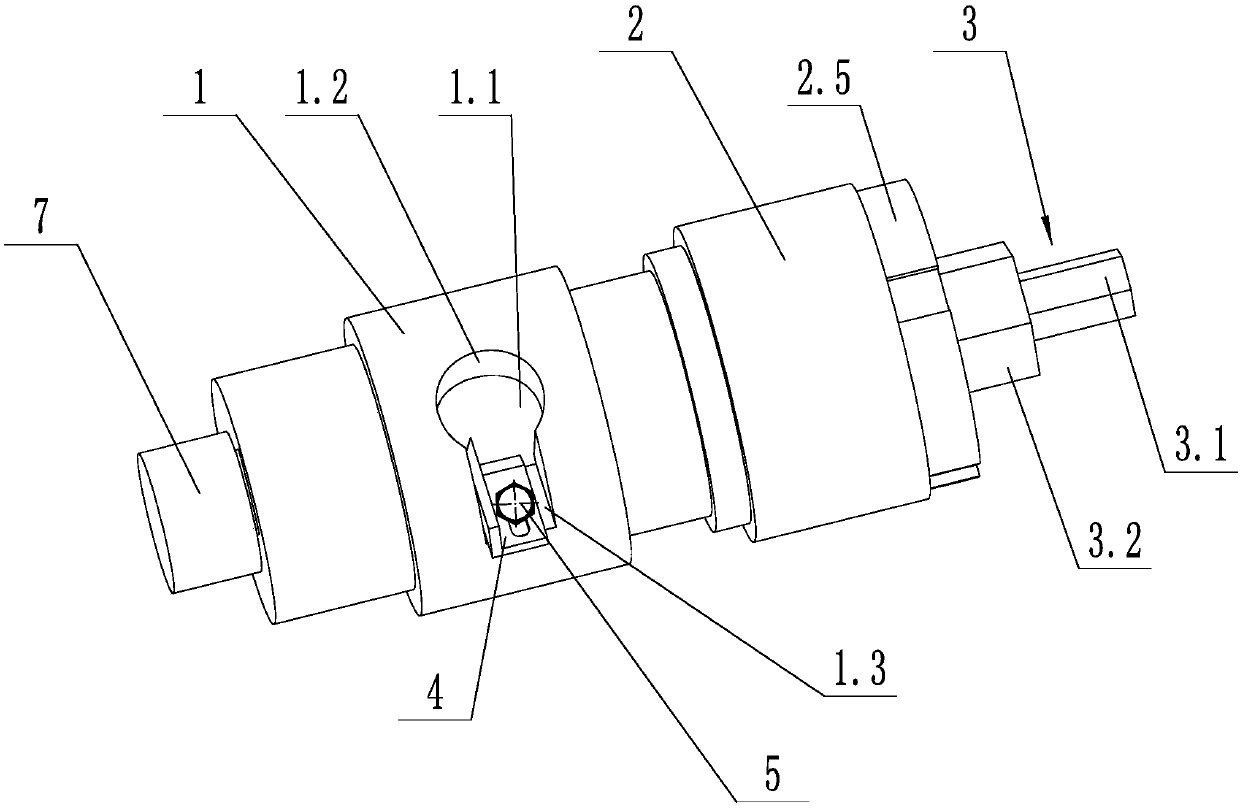

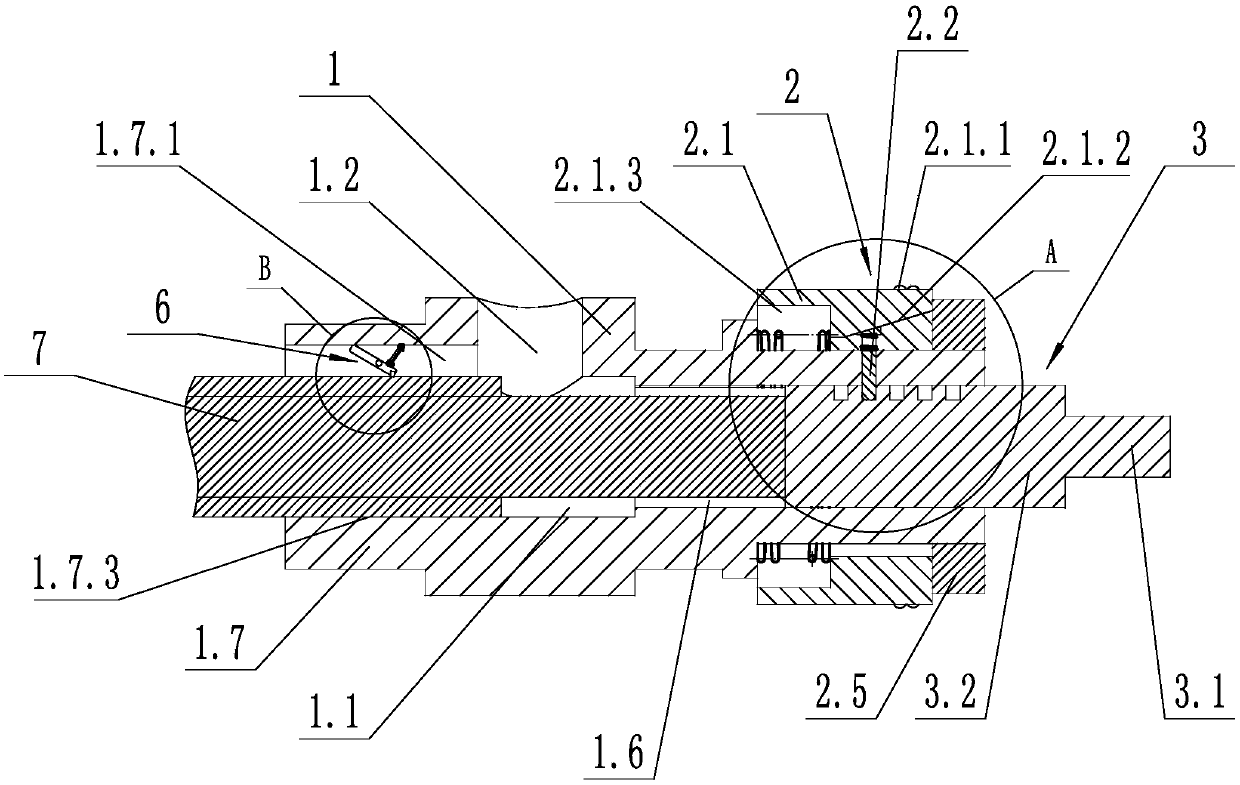

[0025] As shown in the figure, an electric cable insulation layer stripping combination device includes a stripping shaft 1 and a connecting shaft 3, the connecting shaft 3 includes a coaxially connected connecting section 3.1 and an adjusting section 3.2, and the adjusting section 3.2 is coaxial with the stripping shaft 1 Fixed, the connecting section 3.1 is adapted to the gun head of the pistol drill; the center of the stripping shaft 1 is provided with a stripping inner cavity 1.1 for placing the cable 7, and the side wall of the stripping shaft 1 is provided with a chip removal hole 1.2 and a knife groove hole 1.3, the chip removal hole 1.2 is connected with the slit hole 1.3 and connected with the stripping inner chamber 1.1, the slit hole 1.3 is provided with a cutter 4, the blade of the cutter 4 is fixed to the stripping shaft 1, and the cutter 4 The cutting edge faces toward the side of chip removal hole 1.2. The outer insulating layer of the cable can be quickly strip...

Embodiment 2

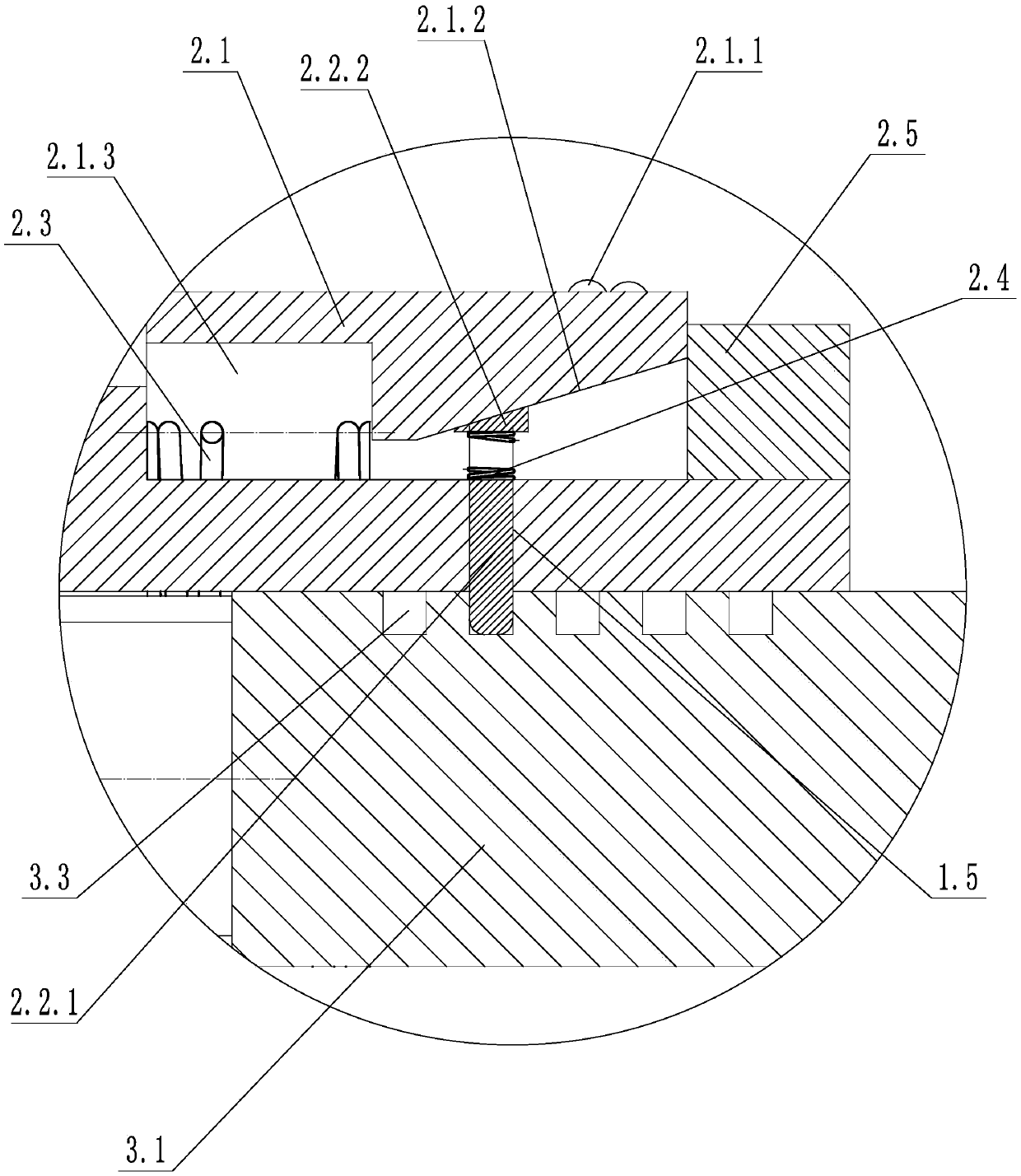

[0029] As shown in the figure, on the basis of Embodiment 1, the side wall of the adjustment section 3.2 is provided with several locking grooves 3.3 distributed along the axis of the connection section 3.1, and the stripping shaft 1 is provided with a slide hole 1.5, an adjustment device 2 and the locking inner cavity 1.6 that communicates with the stripping inner cavity 1.1 and is coaxial; the adjustment section 3.2 is arranged in the locking inner cavity 1.6 and is adapted to the locking inner cavity 1.6, and the adjustment device 2 includes an adjustment sleeve 2.1 , locking piece 2.2, first spring 2.3, second spring 2.4 and locking ring 2.5; the adjustment sleeve 2.1 is coaxially sleeved on the stripping shaft 1, and the inner wall of the adjustment sleeve 2.1 is provided with an adjustment chute 2.1 .2 and the spring ring groove 2.1.3, the first spring 2.3 is coaxially sleeved on the stripping shaft 1 and located in the spring ring groove 2.1.3, one end of the first sprin...

Embodiment 3

[0033] As shown in the figure, on the basis of Embodiment 1 or Embodiment 2, the end of the stripping shaft 1 away from the connecting shaft 3 is provided with a guide sleeve 1.7, and a guide sleeve 1.7 is provided on the guide sleeve 1.7 to communicate with the stripping inner cavity 1.1. Guide cavity 1.7.3, guide sleeve 1.7 and stripping shaft 1 are coaxially fixed, the inner wall of the guide sleeve 1.7 is provided with a mounting groove 1.7.1, and the side wall of the mounting groove 1.7.1 is provided with a rotating hole. A locking device 6 is provided in the groove 1.7.1, and the locking device 6 includes a tension spring 6.1, a locking lever 6.2 and a locking wheel 6.3, and the locking lever 6.2 includes a first locking section 6.2.1, a rotating The shaft 6.2.2 and the second locking section 6.2.3, the quality of the first locking section 6.2.1 is greater than the mass of the second locking section 6.2.3, and the center of gravity of the first locking section 6.2.1 is 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com