A remote monitoring system and method for operating status of an electronic testing instrument

A technology for electronic testing and operating status, which is applied in the transmission system, electrical components, etc., can solve the problems of poor real-time perception and untimely maintenance and maintenance, and achieve the goal of improving the efficiency of status monitoring, enhancing the self-test function and the ability to perceive environmental status Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

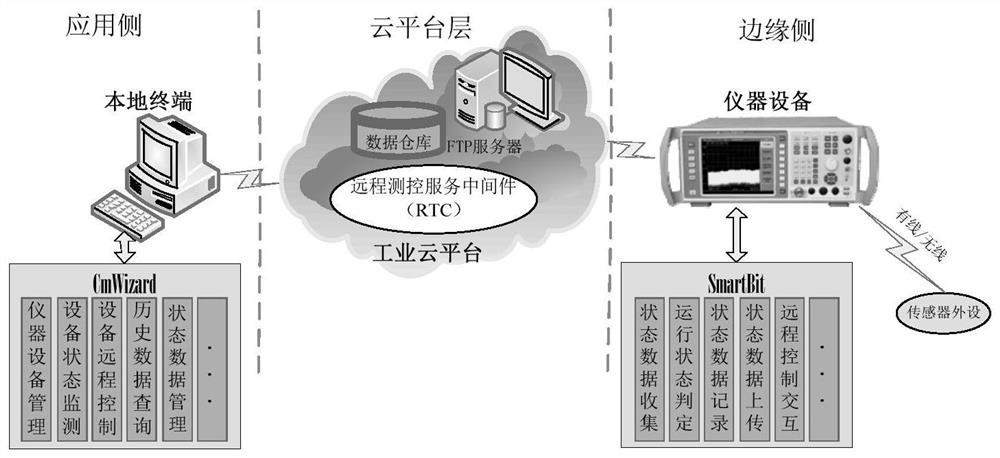

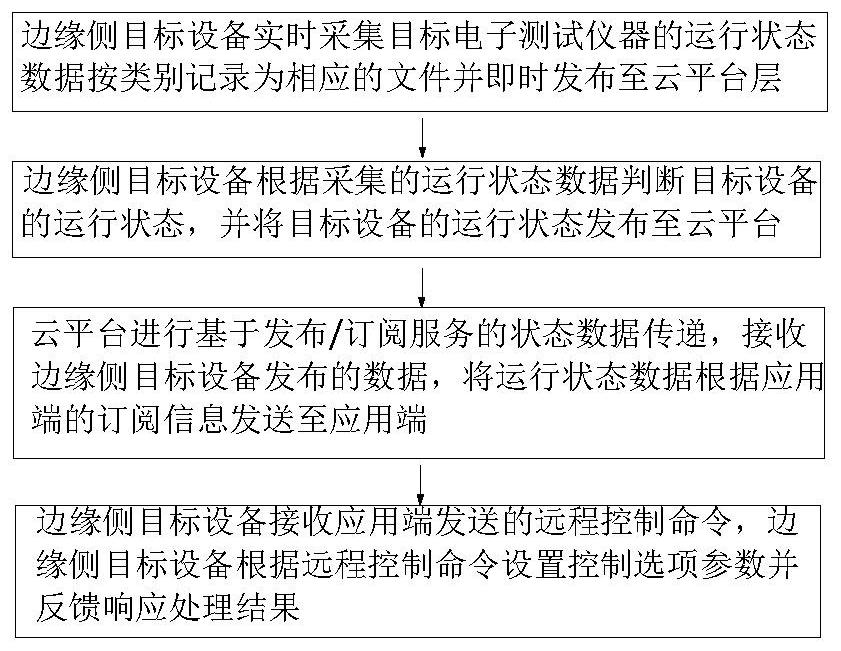

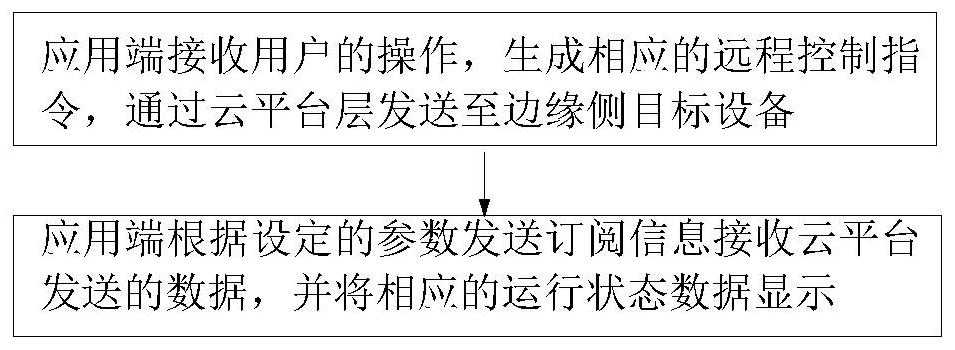

[0049] In the technical solutions disclosed in one or more embodiments, such as figure 1 As shown, a remote monitoring system for the operating status of an electronic test instrument includes an edge side, a cloud platform layer, and an application side connected in sequence, the edge side includes at least one target electronic test instrument, and the target electronic test instrument is set to run in the background The measurement and control task action processing component is used to collect the operating status data of the target electronic test instrument in real time and publish it immediately; the application side sets up a local application terminal (abbreviated as the application terminal) to realize the monitoring of the operating status of the target electronic test instrument on the edge side, Control and management; the cloud platform layer is used to realize the link between the edge side and the application side, and is used to provide database management serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com