On-site treatment equipment for defective cigarettes

A technology for processing equipment and defective cigarettes, which is applied in the fields of tobacco, paper cigarettes, and applications. It can solve the problems of low efficiency, blockage, and unsmooth connection of shredded tobacco, and achieve continuous high-efficiency combing, overcoming large space volume, and overcoming The effect of not easy to separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with specific embodiments.

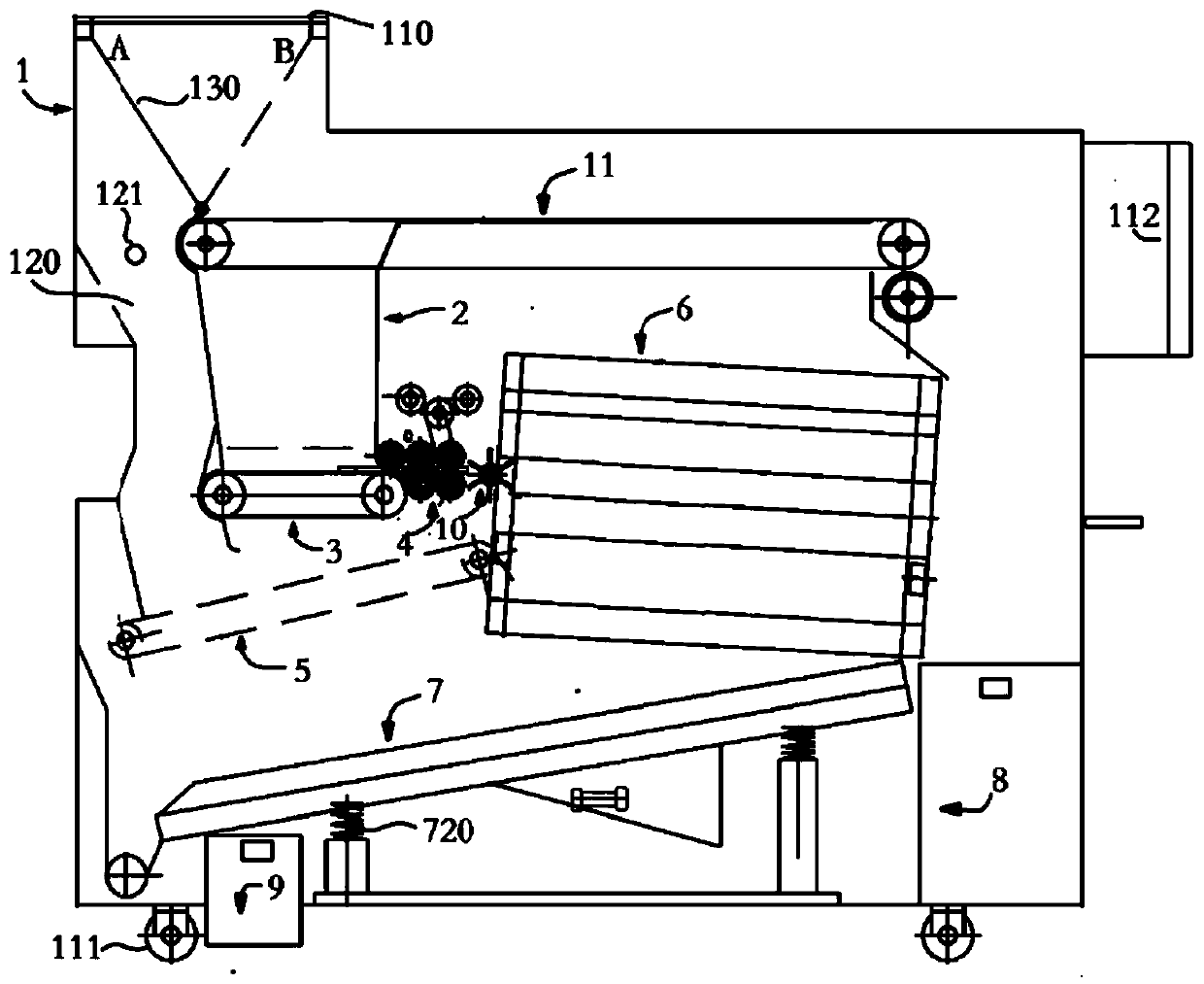

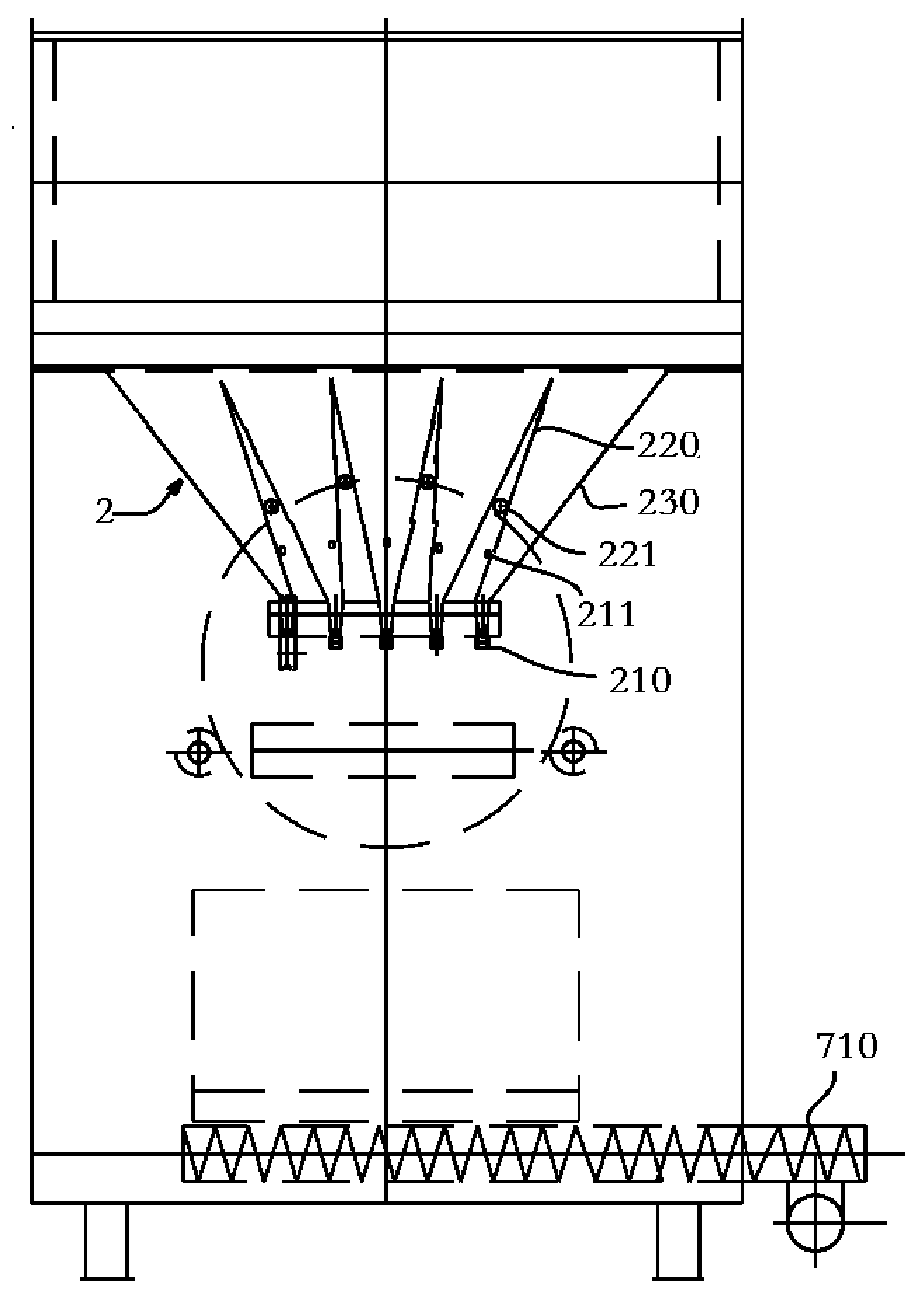

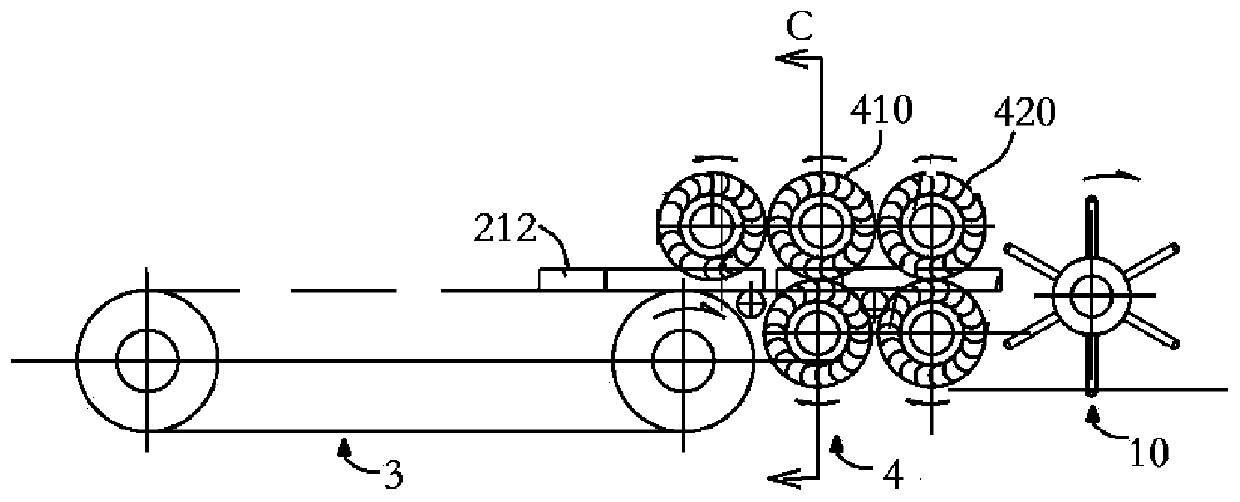

[0049] Such as figure 1 , 2 , 3, the present invention includes a rack box 1, the rack box 1 is provided with a defective cigarette interface 110, and the rack box 1 is provided with a carding device for sorting the conveying direction of defective cigarettes 2. Defective cigarette conveying device 3, cutting device 4 for cutting defective cigarettes and cigarette paper, drum screening device 6 and shredded tobacco vibrating screen for screening cut and defective cigarettes Sub-device 7; the defective cigarette interface 110 of the rack box 1 is facing the defective cigarette inlet of the carding device 2, the conveying device 3 is arranged below the cigarette output slot 210 of the carding device 2, and the output end of the conveying device 3 It extends to the feeding end of the cutting device 4; the discharging end of the cutting device 4 corresponds to the feeding por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com