Full-automatic opening and closing vertical supercritical fluid foaming equipment

A technology of supercritical fluid and foaming equipment, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of unfavorable safety production and high labor intensity of manual operation, and reduce work The effect of increasing strength, improving production efficiency, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 kettle body sealing process

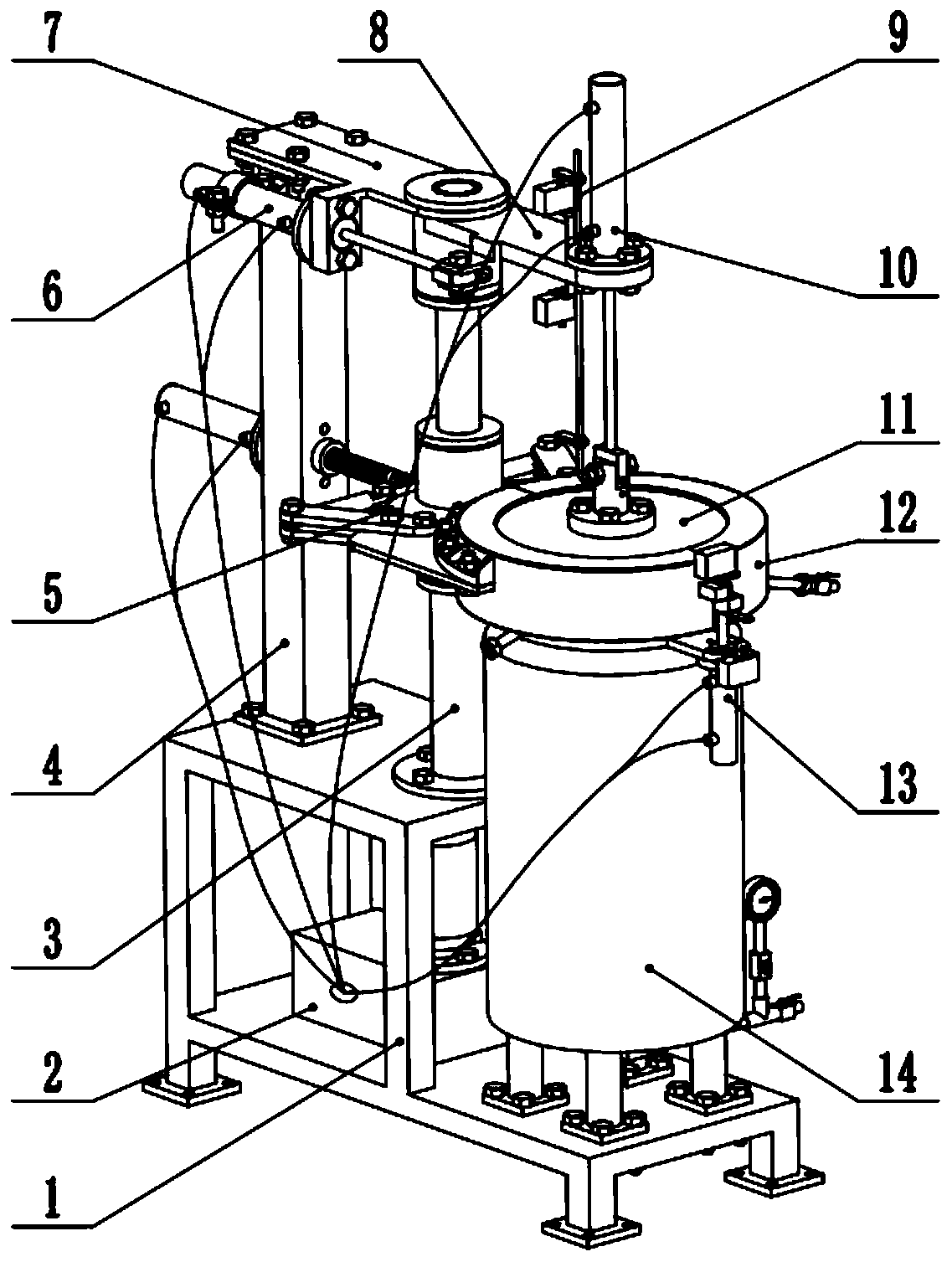

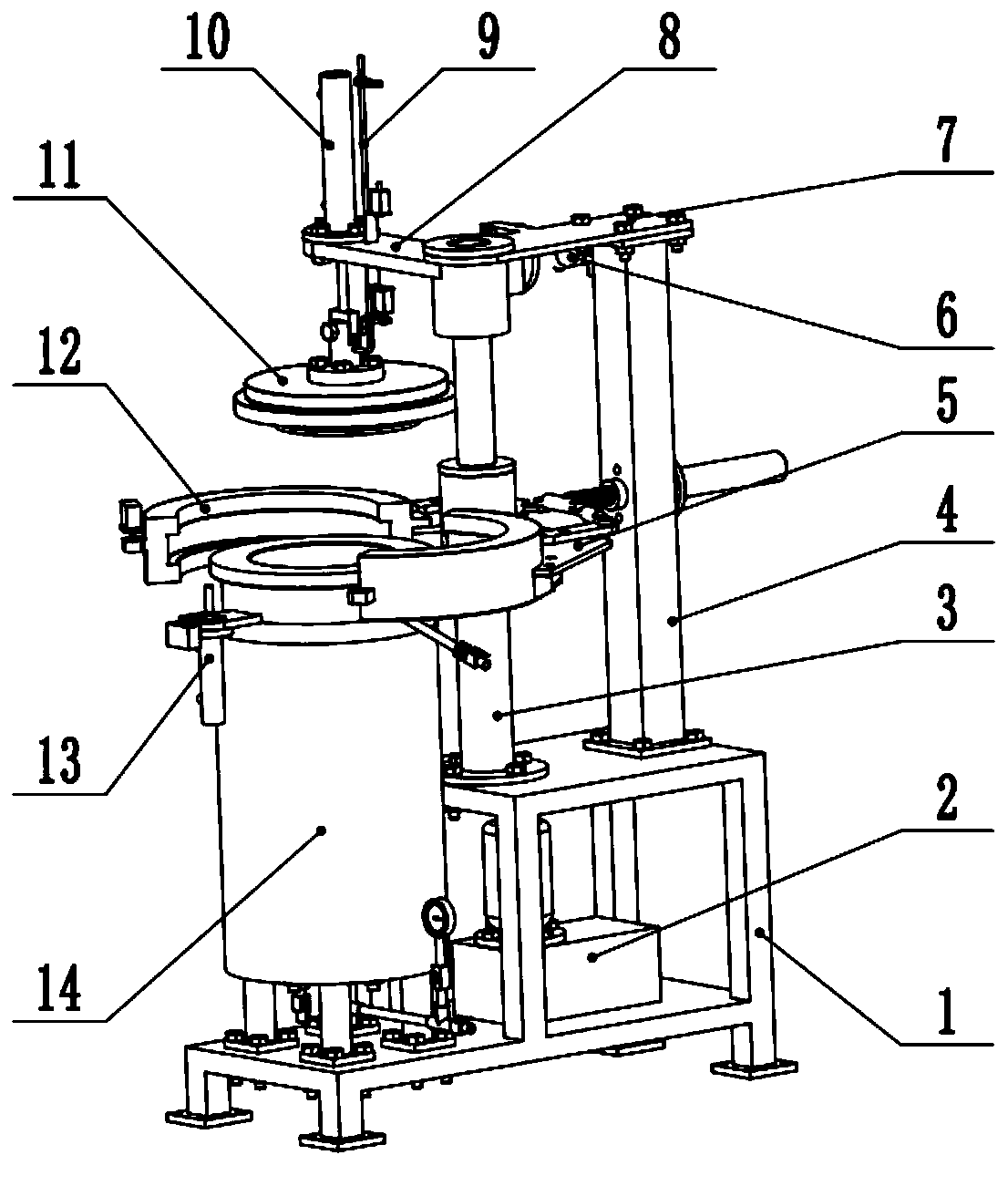

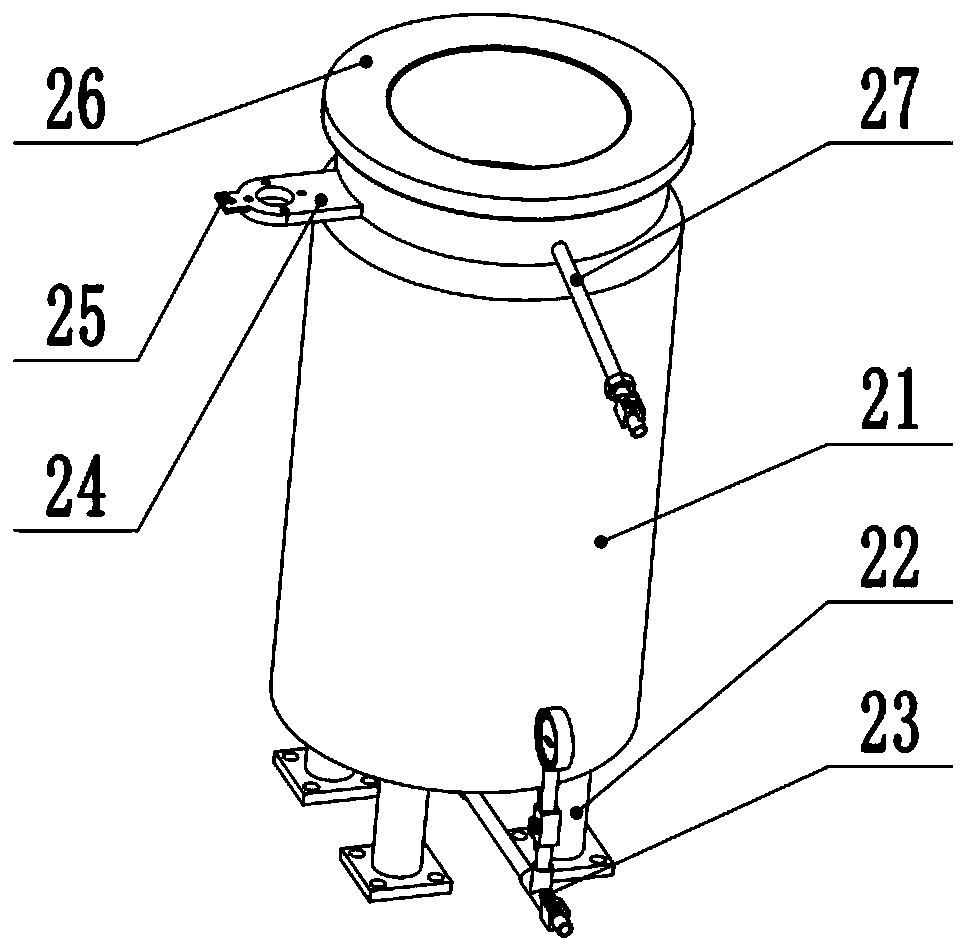

[0045] Refer to attached figure 1 to attach Figure 9 , first, install the sealant strip in the sealing groove (92) of the gland (41); then start the closing operation button of the device, and the control system will automatically work according to the following steps.

[0046] 1) The rotating arm moving device (6) pushes the rotating arm (8) to rotate towards the kettle body (21), and when the gland (41) reaches directly above the kettle body (21), the rotating arm (8) stops moving;

[0047] 2) The cover push-pull device (10) moves downward, and the connecting piece (42) drives the limit guide rod (51) to move downward. When the upper limit plate (56) approaches the upper proximity sensor (55), the cover push-pull device (10 ) stop motion, the gland matching end (91) of the gland (41) cooperates with the mouth of the kettle body (21) to compress, and the gland locking end (93) of the gland (41) and the kettle body (21) The...

Embodiment 2

[0051] Embodiment 2 Kettle body opening process

[0052] Refer to attached figure 1 to attach Figure 9 , First, complete the pressure relief in the kettle; then start the closed operation button of the equipment, and the control system will automatically work according to the following steps.

[0053] 1) The push rod of the clamp lock push-pull device (71) of the clamp lock device (13) moves downward, when the stopper (73) on the push rod of the clamp lock push-pull device (71) and the proximity sensor A (72) When approaching, the locking ears (83) of a pair of clamp A (31) and clamp B (32) are no longer in the locked state, and the clamp locking push-pull device (71) stops moving;

[0054] 2) The clamp opening and closing push-pull device (36) of the clamp opening and closing assembly (5) pulls a pair of clamps to rotate around the column A (3) through the connecting rod (34), and the pair of clamps A (31) and the clamps Hoop B (32) is separated from the fully aligned gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com