A method for preparing lead-based metal organic framework phosphorescent material

A technology of organic frameworks and phosphorescent materials, applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of complex synthesis conditions, short phosphorescent lifetime, poor stability, etc., and the method is simple , Improve rigidity, improve phosphorescence efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In Embodiment 1, the method for preparing a lead-based metal organic framework phosphorescent material comprises the following steps:

[0031] S1: Mix 0.7mol lead nitrate and 0.1mol terephthalic acid, add 40mL N,N-dimethylformamide, stir until completely dissolved to obtain a clear solution;

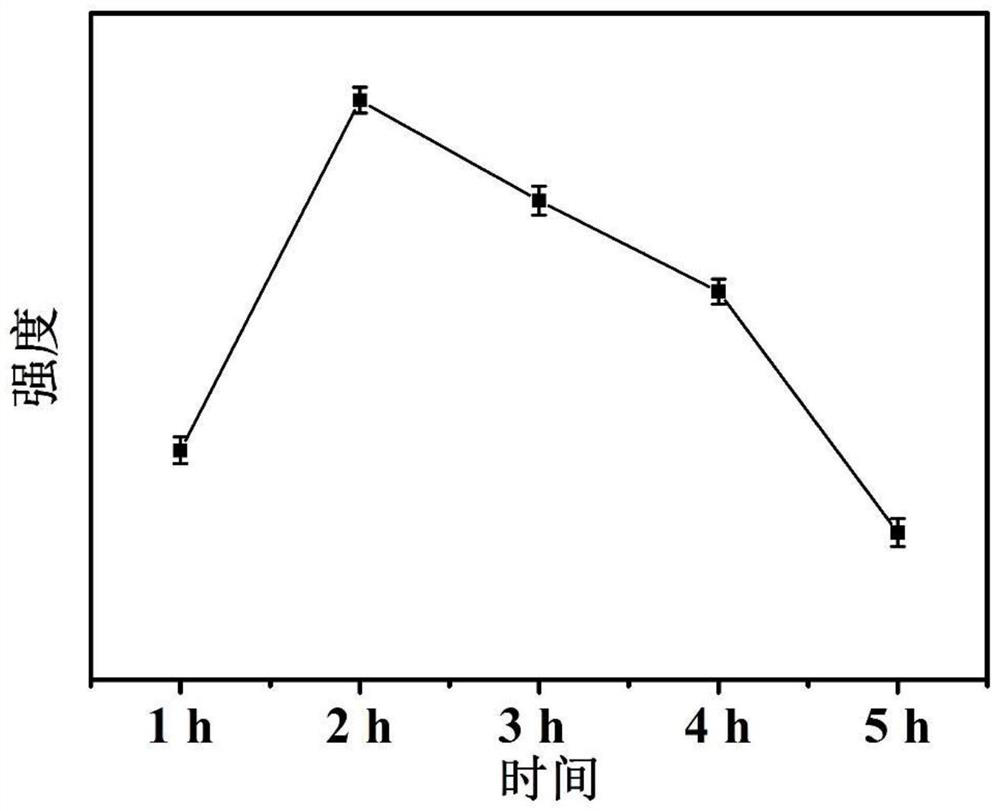

[0032] S2: Add 2.3 mL of triethylamine to the clear solution while stirring, and stir at room temperature for 1 h, 2 h, 3 h, 4 h and 5 h respectively, so that the clear solution becomes a milky white turbid liquid;

[0033] S3: The milky white turbid liquid was collected by centrifugation, and then washed with N,N-dimethylformamide to remove unreacted lead nitrate and terephthalic acid, and soaked in dichloromethane for 2 days to remove the N adsorbed in the product. , N-dimethylformamide, vacuum drying to obtain the target product.

[0034] Washing was performed by two dissolutions and centrifugation using N,N-dimethylformamide.

[0035] figure 1 Indicates the effect of stirri...

Embodiment 2

[0037] In Example 2, the method for preparing a lead-based metal organic framework phosphorescent material comprises the following steps:

[0038] S1: Mix 0.7mol lead nitrate and 0.1mol terephthalic acid, add 40mL N,N-dimethylformamide, stir until completely dissolved to obtain a clear solution;

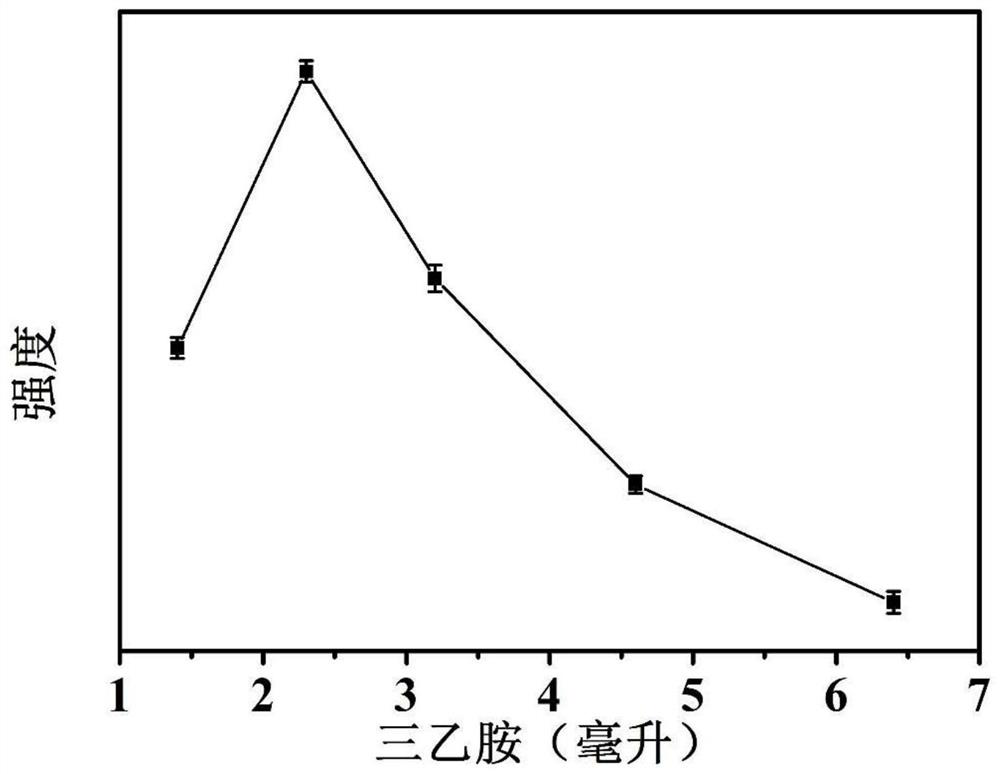

[0039]S2: While stirring, add 1.6mL, 2.3mL, 3.2mL, 4.6mL and 6.4mL of triethylamine to the clear solution respectively, and stir at room temperature for 2h, so that the clear solution becomes a milky white turbid liquid;

[0040] S3: The milky white turbid liquid was collected by centrifugation, and then washed with N,N-dimethylformamide to remove unreacted lead nitrate and terephthalic acid, and soaked in dichloromethane for 2 days to remove the N adsorbed in the product. , N-dimethylformamide, vacuum drying to obtain the target product.

[0041] Washing was performed by two dissolutions and centrifugation using N,N-dimethylformamide.

[0042] figure 2 Indicates the effect of th...

Embodiment 3

[0044] In embodiment three, the method for preparing a lead-based metal organic framework phosphorescent material comprises the following steps:

[0045] S1: Mix lead nitrate and terephthalic acid in a molar ratio of 5:1, 6:1, 7:1, 8:1, 9:1, 10:1, then add 40mL N,N-dimethylformaldehyde Amide, stirred until completely dissolved to obtain a clear solution;

[0046] S2: Add 2.3 mL of triethylamine to the clear solution while stirring, and stir at room temperature for 2 hours, so that the clear solution turns into a milky white turbid liquid;

[0047] S3: The milky white turbid liquid was collected by centrifugation, and then washed with N,N-dimethylformamide to remove unreacted lead nitrate and terephthalic acid, and soaked in dichloromethane for 2 days to remove the N adsorbed in the product. , N-dimethylformamide, vacuum drying to obtain the target product.

[0048] Washing was performed by two dissolutions and centrifugation using N,N-dimethylformamide.

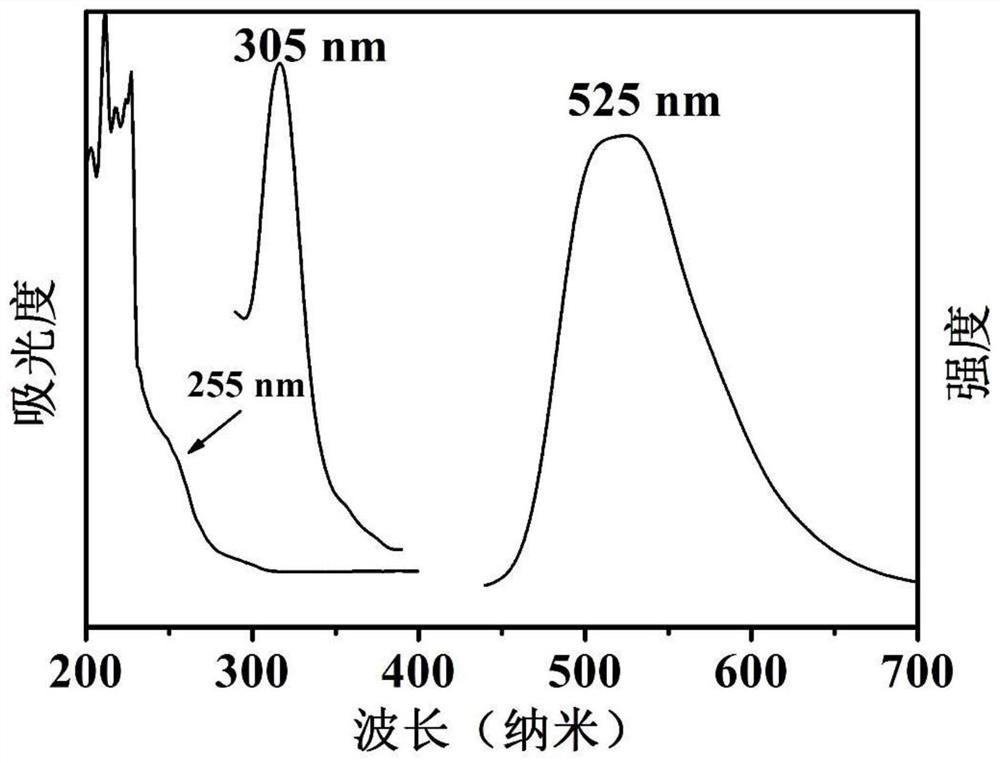

[0049] image 3 R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com