Train anti-skid control method based on optimal slip rate and control device thereof

A slip rate, optimal technology, applied in the direction of brakes, pneumatic brakes, transportation and packaging, etc., can solve the problem of the optimal slip rate change of the adhesion coefficient between the train wheel and rail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be further described below in conjunction with examples.

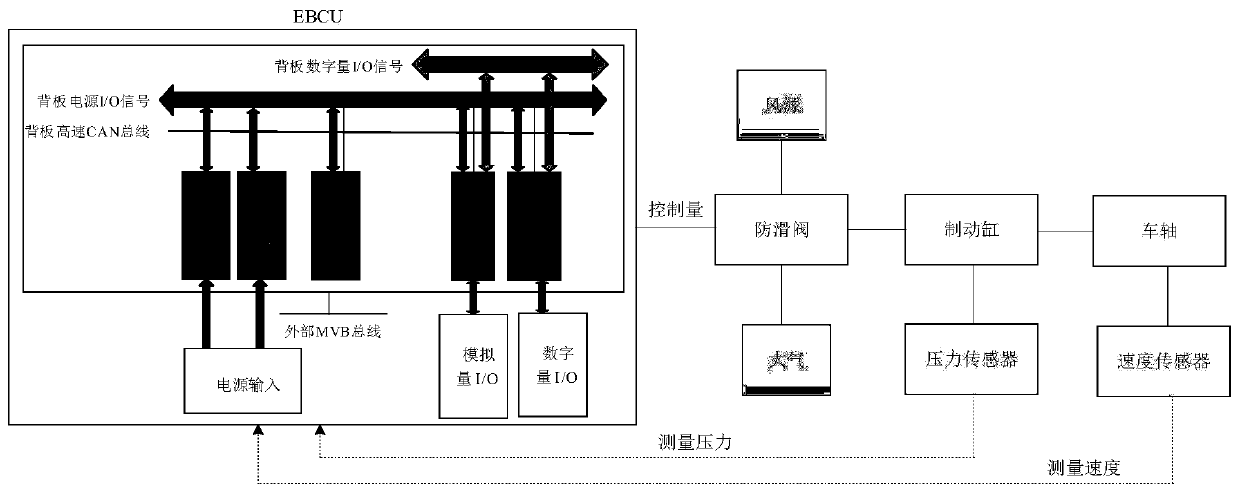

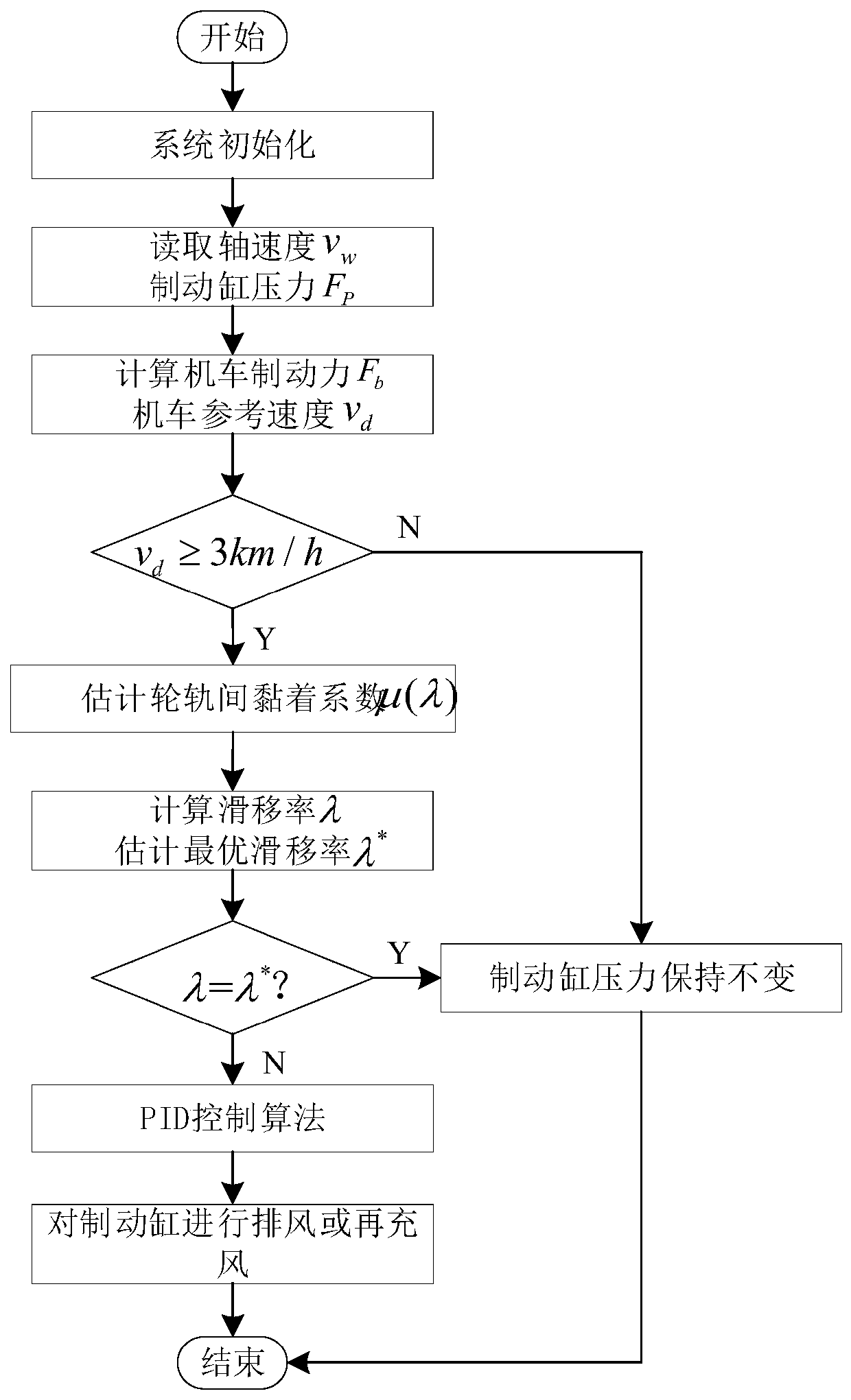

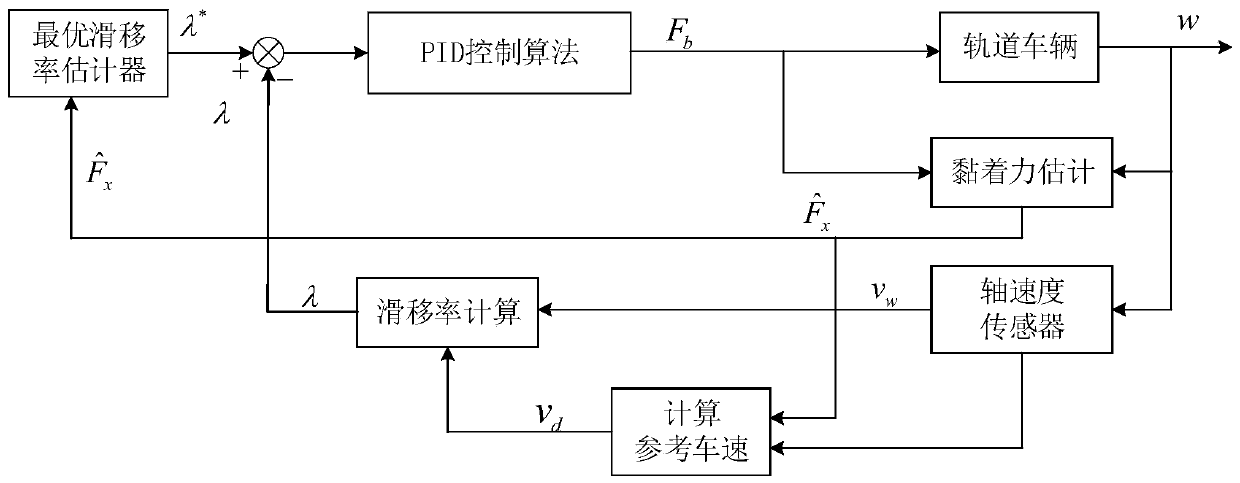

[0074] Such as figure 1 As shown, the train anti-skid control device provided by the present invention includes an electronic brake control unit (EBCU), an air source system, an anti-skid valve, a pressure sensor, a speed sensor and a brake cylinder, wherein the anti-skid valve is connected with the air source system, the brake cylinder The air source system and the atmosphere are connected to the brake cylinder through the anti-skid valve, and the electronic brake unit is connected to the brake cylinder through the anti-skid valve. It exhausts or refills the brake cylinder by controlling the anti-skid valve switch to Adjust the brake cylinder pressure until the solved braking torque is reached. The pressure sensor collects the pressure in the brake cylinder in real time, and the speed sensor collects the wheel set speed in real time. Both the pressure sensor and the speed sensor are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com