Full-automatic control method for quantitative loading of aggregate and gravel

A control method and fully automatic technology, applied in loading/unloading, transportation and packaging, instruments, etc., can solve the problems of low level of operators, weak technology accumulation, favoritism and fraud, etc., to ensure uniqueness and reduce excessive costs , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

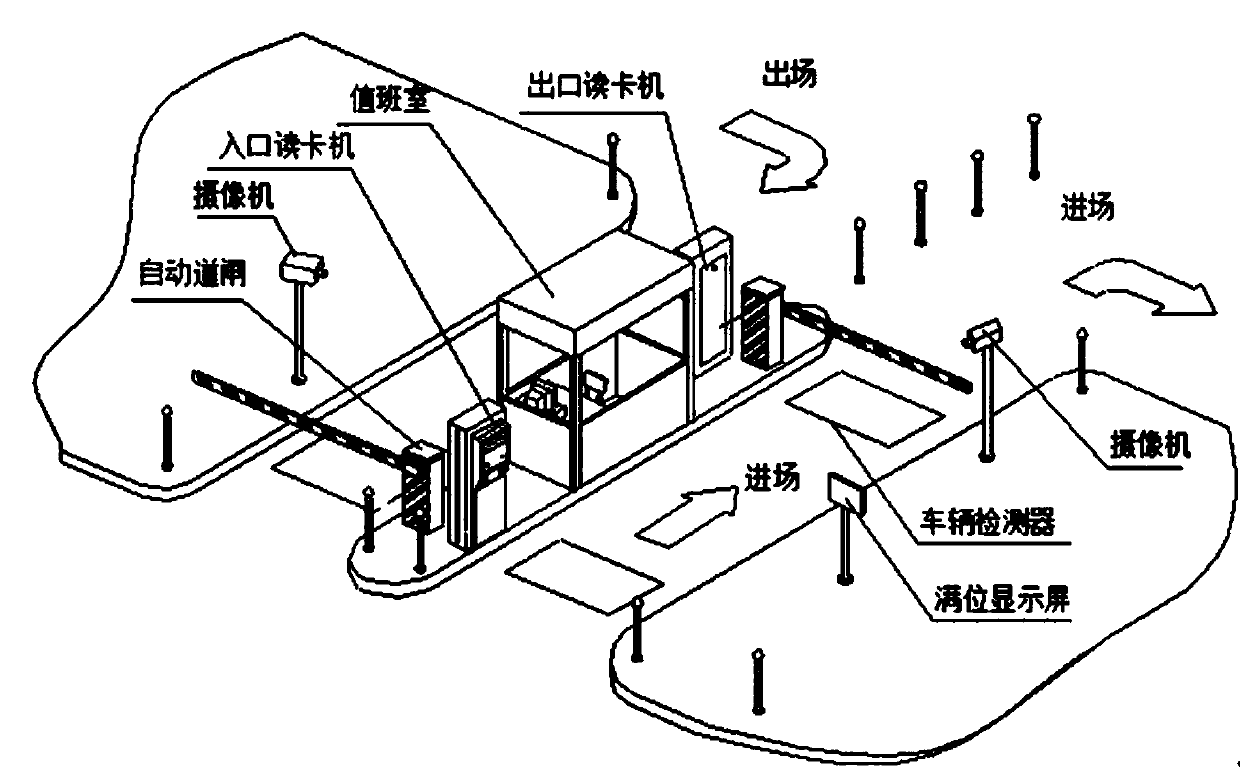

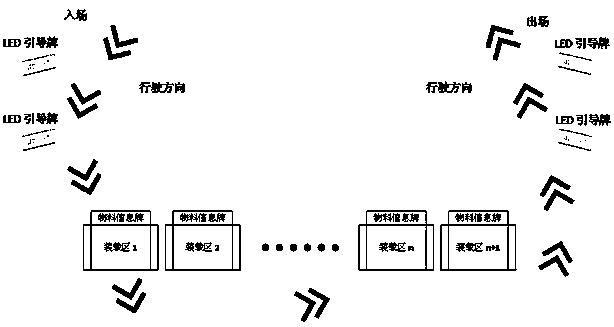

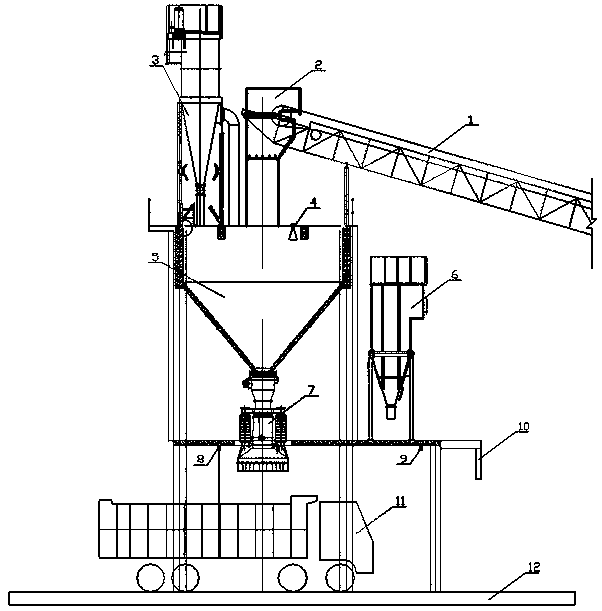

[0045] The invention is a fully automatic control method for quantitative loading of aggregates and gravels. The invention uses the order management system, vehicle access control and license plate recognition system, product inventory, vehicle positioning, bulk machine control, weighbridge control and DCS The control system implements the whole process control of the quantitative loading of aggregates and finished sand and gravel products, and realizes aggregate and gravel from online reservation, card pick-up at the factory, card entry into the factory, loading at the loading space, automatic weighing, and printing of the weighing list Factory fully automatic control process.

[0046] to combine figure 1 , the present invention is equipped with an access control license plate recognition system in the area entering and leaving the factory. The access control license plate recognition system includes a camera, a full-position display screen, an automatic barrier, a vehicle de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com