Method for controlling arsenic sulfide residue leaching reaction endpoint

A reaction terminal, arsenic sulfide technology, applied in the direction of process efficiency improvement, etc., can solve the problems of incompleteness, energy consumption reaction, temperature drop-pressure relief-sampling-heating-pressurization and other cumbersome work, so as to reduce workload, The effect of liquid component stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

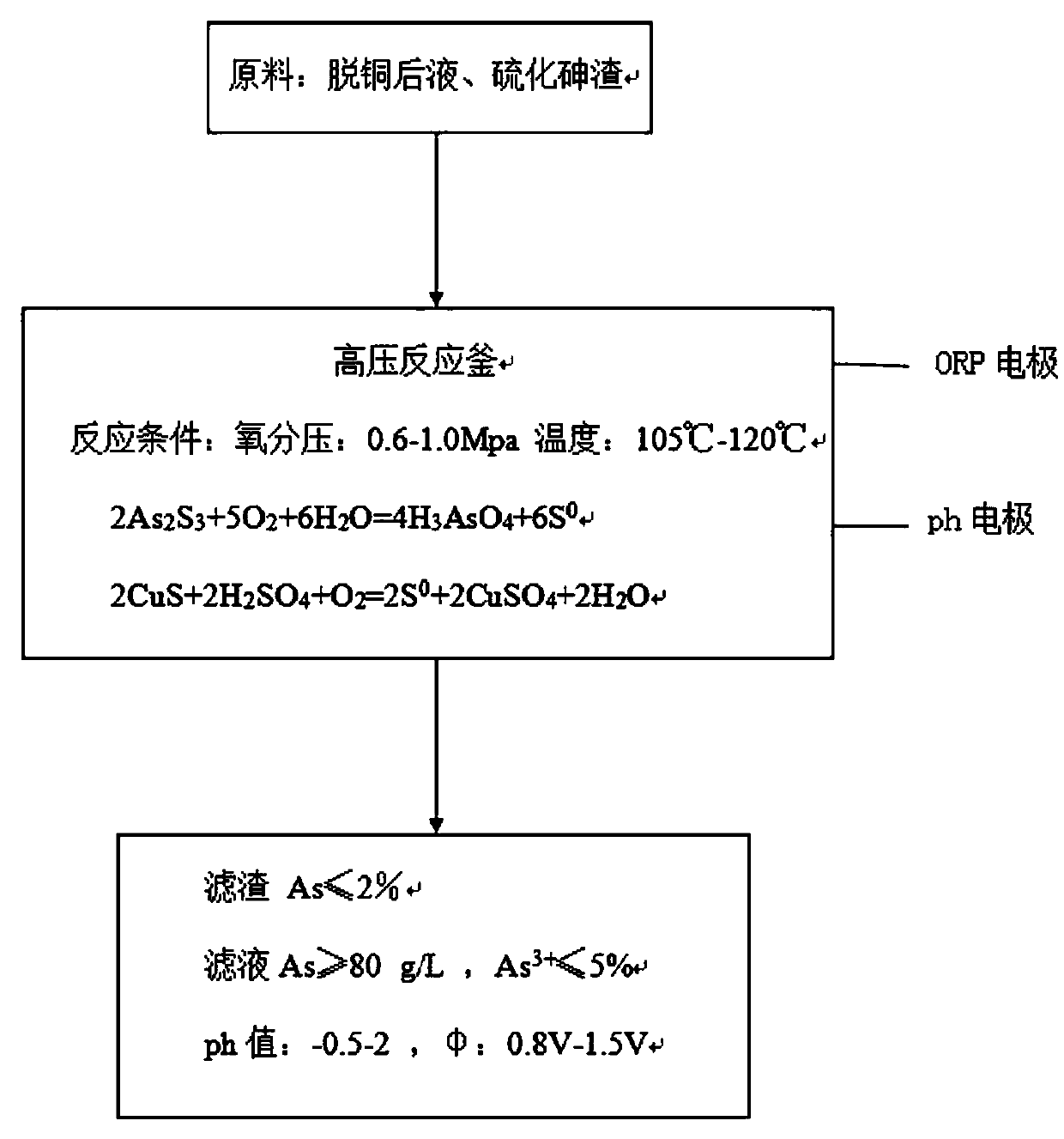

Method used

Image

Examples

Embodiment 1

[0023]

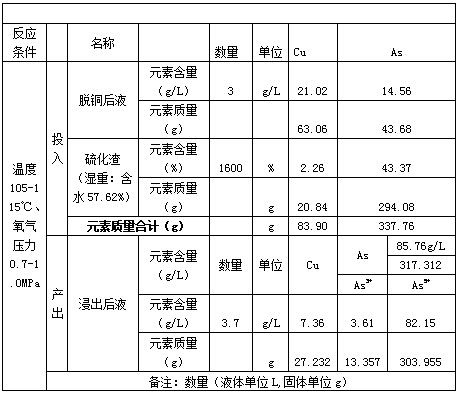

[0024] Table 1)

[0025] Example illustration: when the reaction time is 1.5h, the ph value of the reaction solution is 0.5, and the ORP potential potential is 0.9V; the sampling test results are shown in Table (1), and the calculated arsenic sulfide slag leaching rate is 94.06%, trivalent Arsenic accounts for 95.59% of the total arsenic content.

Embodiment 2

[0027]

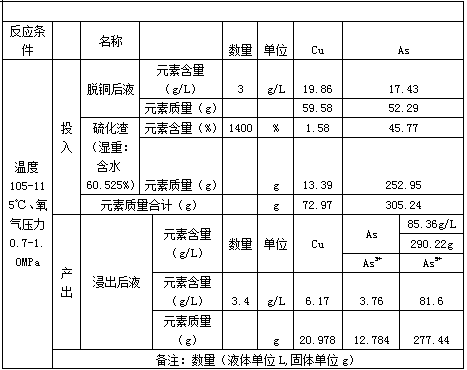

[0028] Table 2)

[0029] Example illustration: when the reaction time is 1 hour and 50 minutes, the ph value of the liquid after the reaction is 0.6, and the ORP potential potential is 0.85V; the sampling test results are shown in Table (2), and the calculated arsenic sulfide leaching rate is 93.05%. Trivalent arsenic accounts for 95.79% of the total arsenic content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com