Lightweight wear-resistant engine piston insert ring

An engine and lightweight technology, applied to engine components, machines/engines, engine sealing devices, etc., can solve problems such as inconvenient piston vibration, imperfect auxiliary sealing structure, and insufficient structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

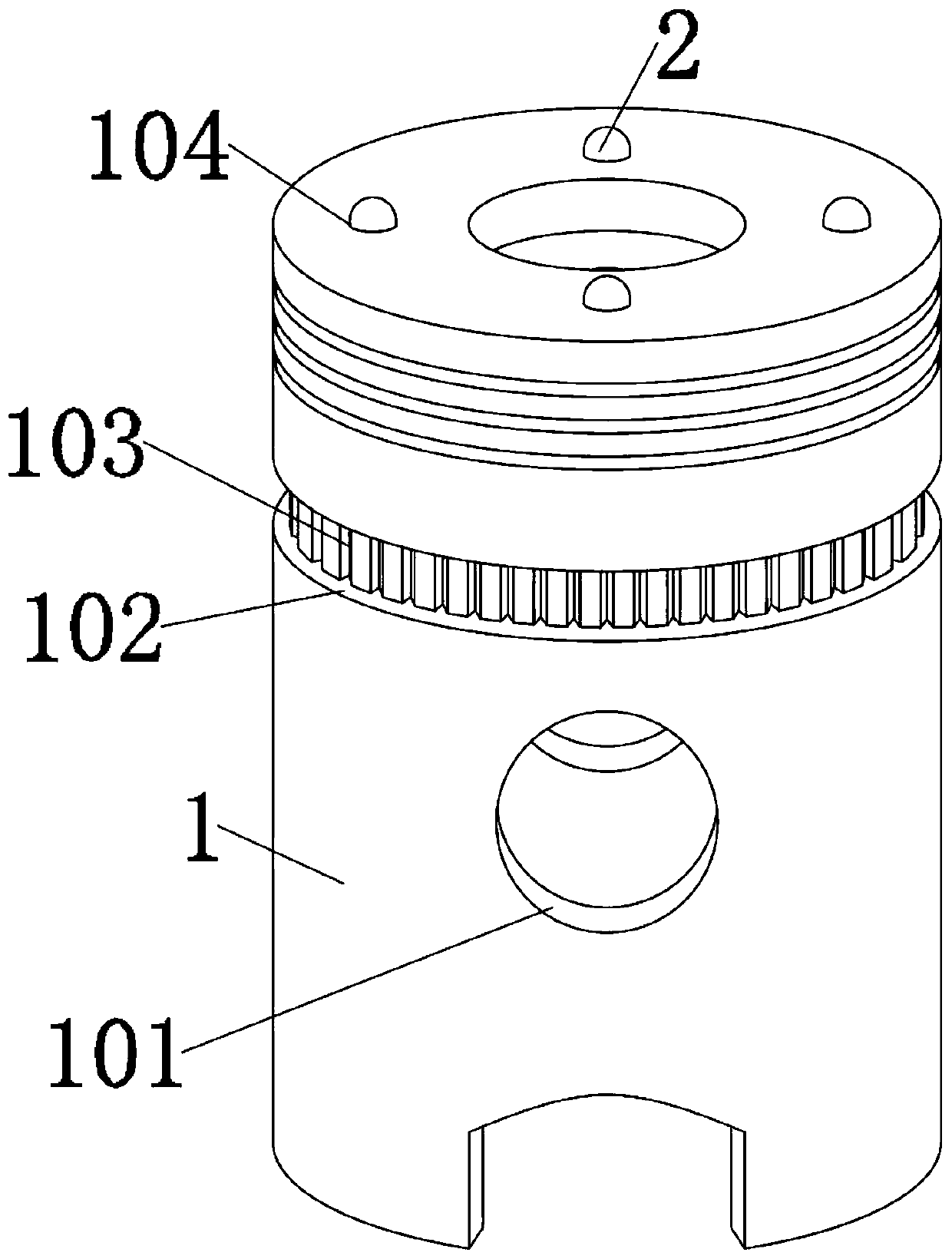

[0024] As attached figure 1 Attached Figure 4 Shown:

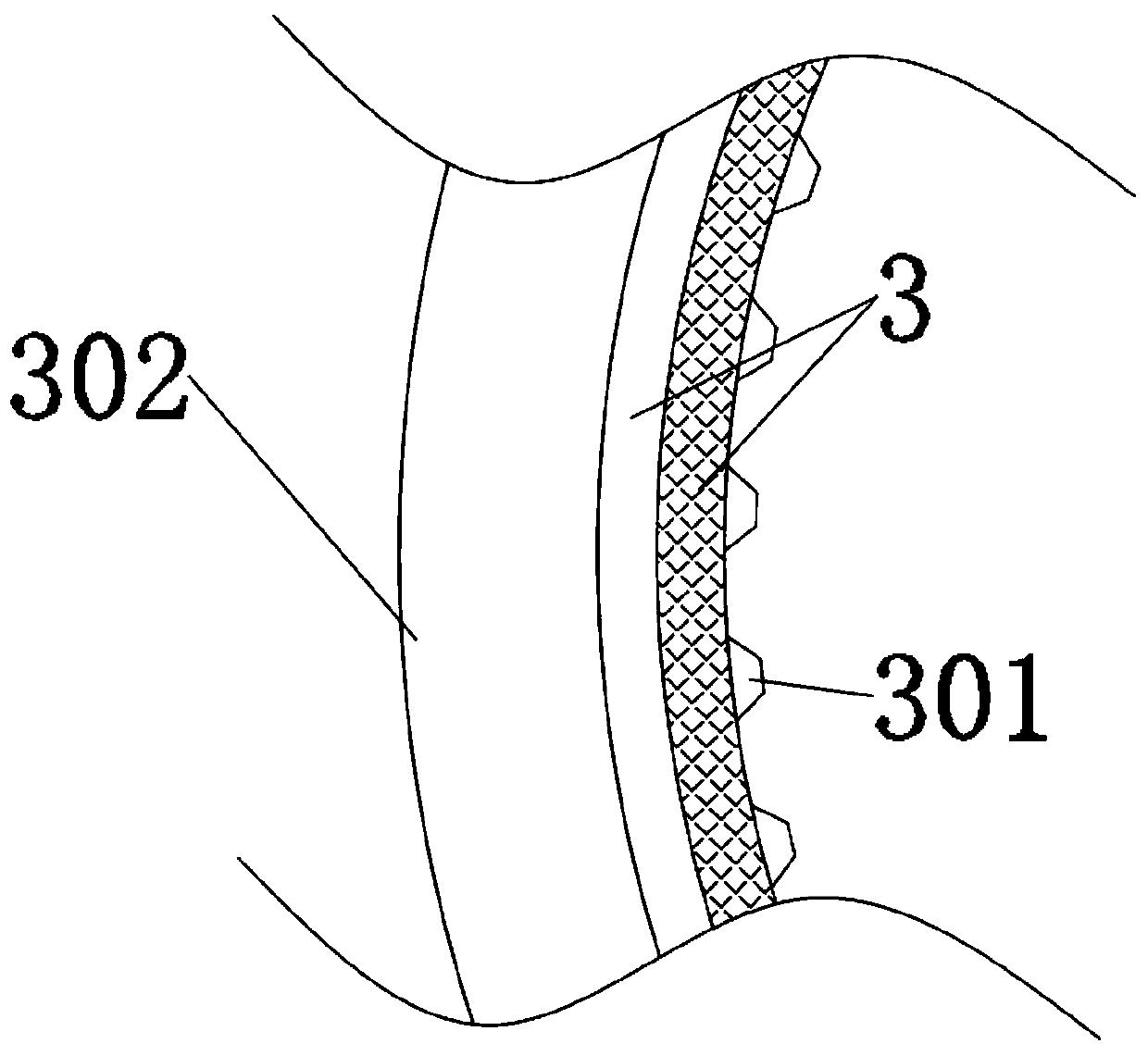

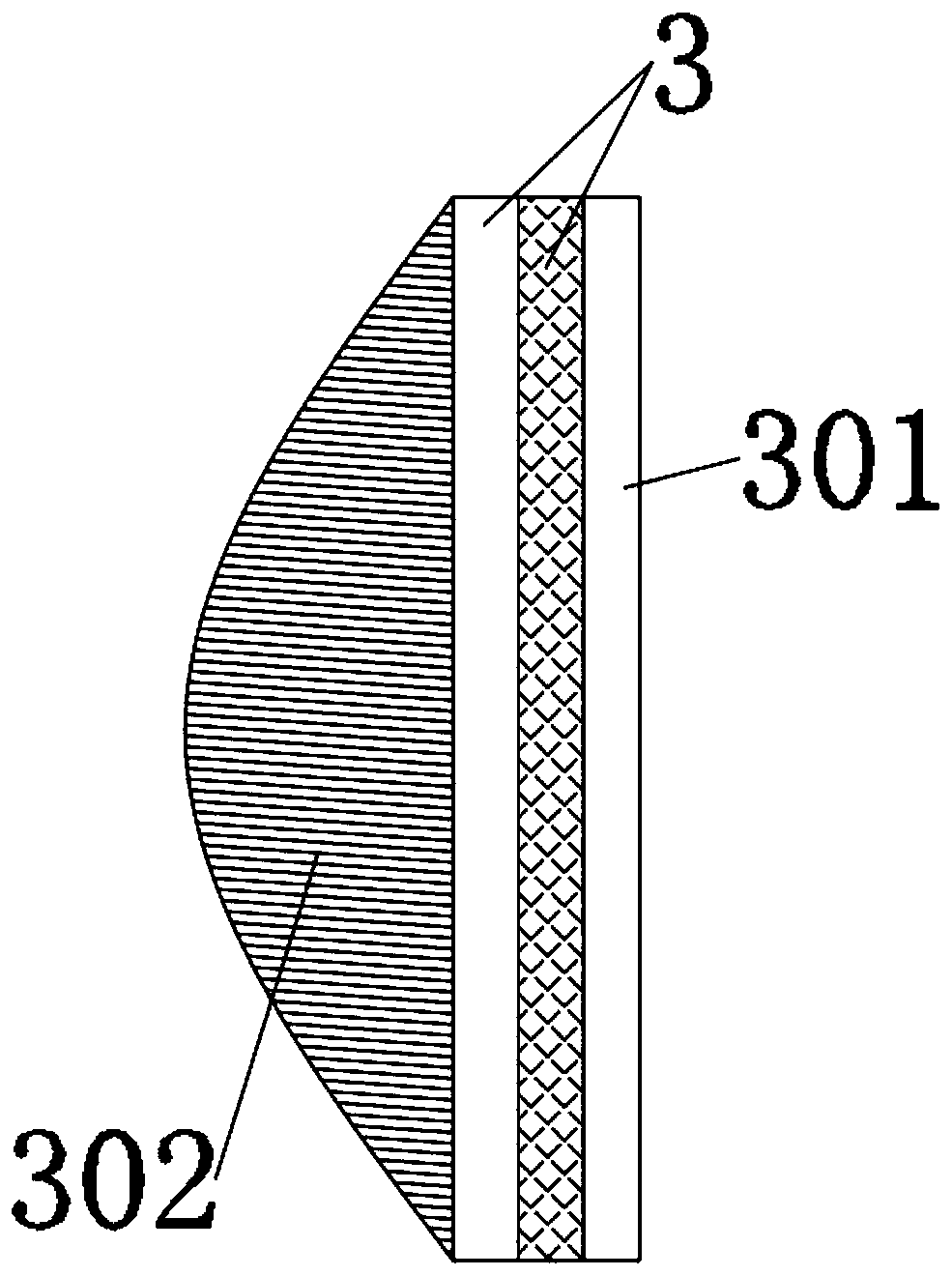

[0025] The present invention provides a lightweight wear-resistant engine piston insert, which includes a main body 1, a connecting hole 101, an embedding groove 102, an auxiliary groove 103, a mounting groove 104, a top piece 105, a spring 106, a buffer piece 2, and an inner groove 201 , The connecting groove 202, the sleeve 3, the insert 301 and the contact 302; the main body 1 is a cylindrical hollow structure, the bottom of the main body 1 is provided with a groove, and the center of the main body 1 is provided with a circular The connecting hole 101 of the structure is connected with the power arm, and the sleeve 3 is embedded and installed in the insertion groove 102, and the insert 301 is embedded and installed in the auxiliary groove 103; the top piece of the installation groove 104 A spring 106 is installed on the outside of 105; the buffer member 2 is installed in the mounting groove 104 above the main body 1 by e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com