Concrete delivery pump pipe connection transfer structure and construction method thereof

A technology for concrete delivery pumps and conversion structures, which is applied in the direction of flange connections, sleeve/socket connections, pipes/pipe joints/pipe fittings, etc., which can solve the difficulty in ensuring the quality control of concrete pouring, reduce construction production efficiency, and concrete steel pump pipes It can improve the pumpability, reduce the quality and safety accidents, and improve the pumping efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

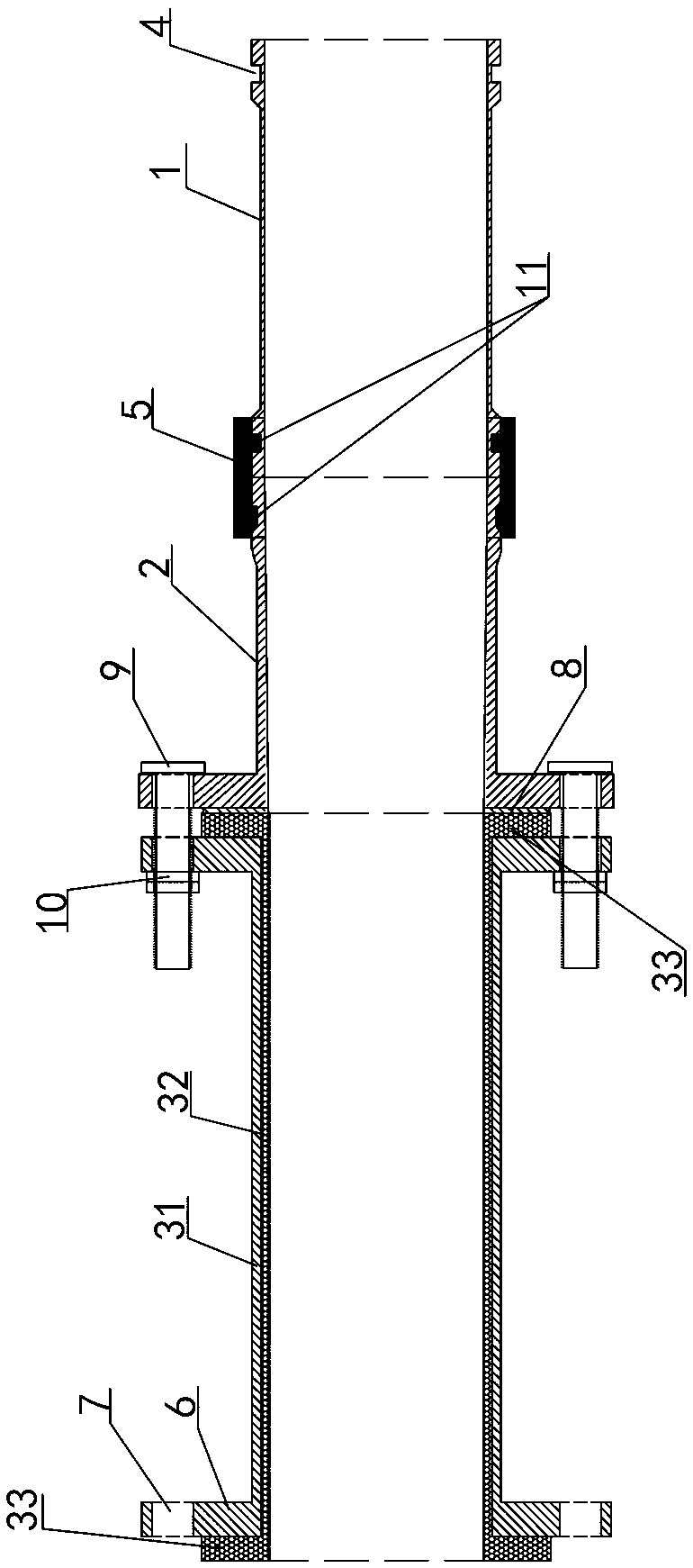

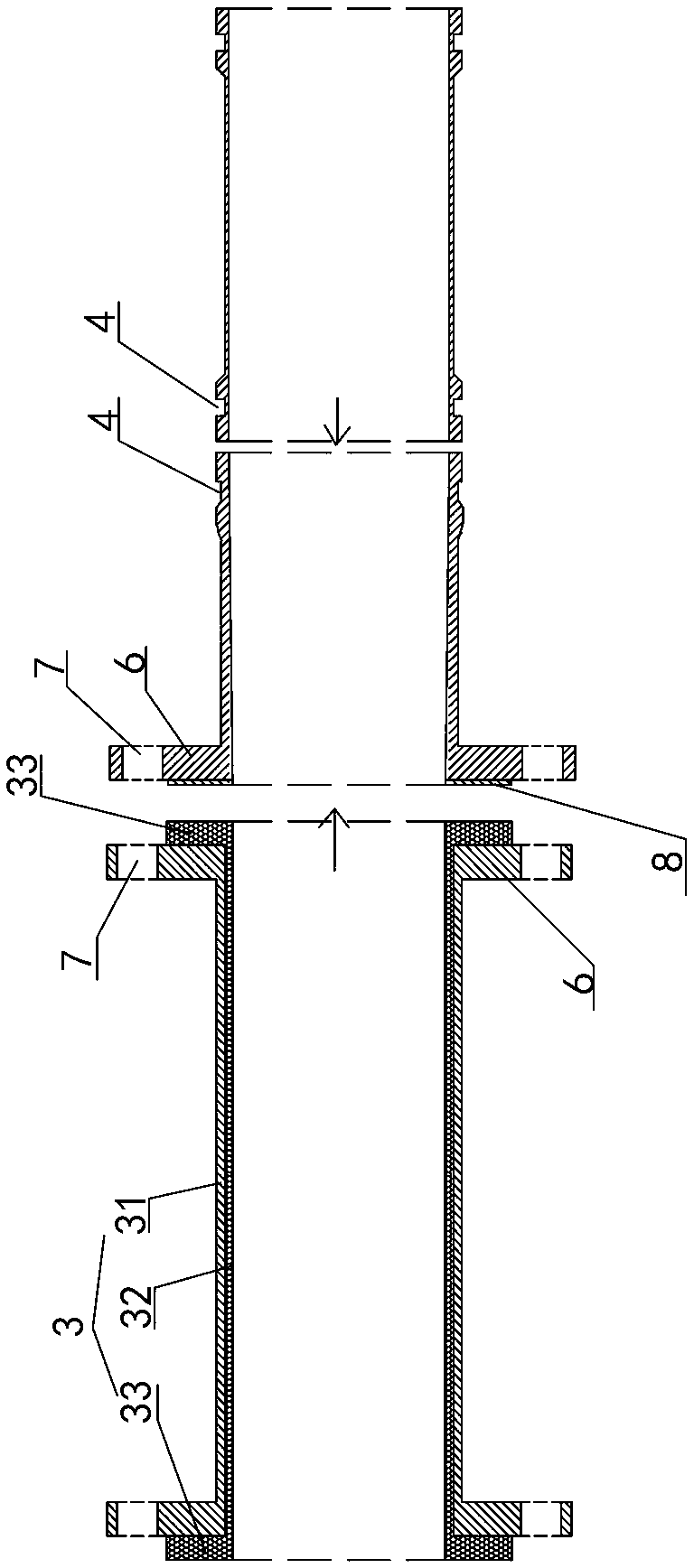

[0055] see Figure 1-6 As shown, a concrete delivery pump pipe connection conversion structure includes the original pump pipe 1, the original pump pipe 1 is a steel pipe, and the outer walls of the two ends of the original pump pipe 1 are provided with ring-shaped recesses for buckle locking. The tank 4 also includes a conversion pump tube 2 and a composite pump tube 3 communicating with the original pump tube 1 through the conversion pump tube 2 .

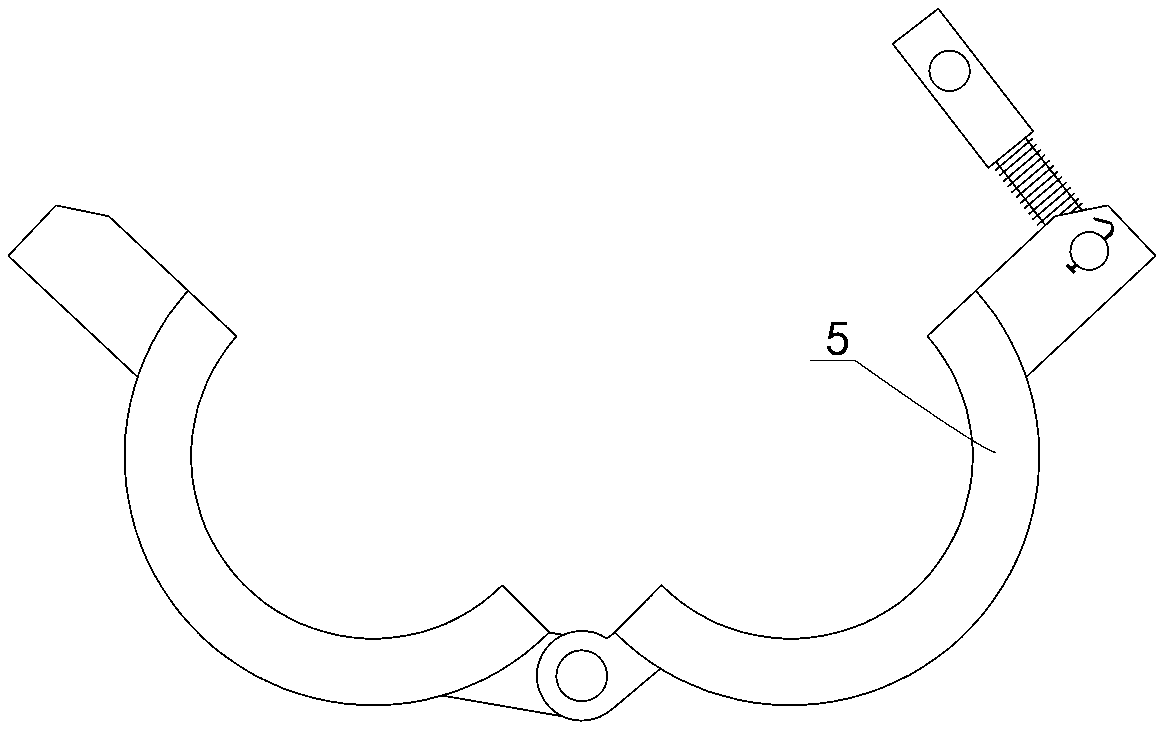

[0056] The conversion pump pipe is a steel pipe, including a conversion pipe body and connection ends on both sides, the connection end on one side is a buckle connection end, and the outer wall of the conversion pipe at the buckle connection end is also provided with a buckle lock. An annular groove 4, the connecting end of the original pump tube and the annular groove on the buckle connecting end are locked and connected together by the buckle 5 cushioned with a rubber gasket 11 .

[0057] The connection end on the other side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com