Rapid blasting groove broaching method suitable for different sectional heights

A kind of grooving and fast technology, which is used in blasting, earth-moving drilling, surface mining, etc., can solve the problems of low grooving efficiency, easy failure, low success rate, etc., and achieves high grooving efficiency, strong adaptability, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

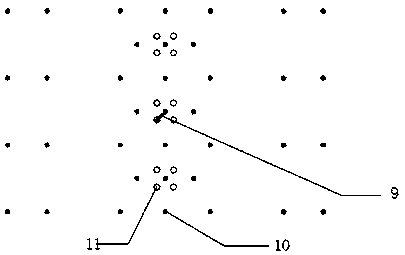

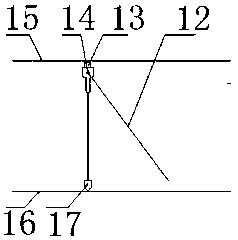

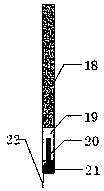

[0020] Embodiment 1: see Figure 1-Figure 5 , a rapid blasting slotting method suitable for different segment heights, the method includes the following steps: 1) design of the slotting hole, 2) precise positioning of the blasting hole construction, 3) reasonable charge structure selection, 4) reasonable Determination of segmental differential delay, 5) selection of reasonable blocking length, 6) judgment of slotting blasting effect, the steps 1) design of slotting blast holes are as follows, the core part adopts vertical hole slotting method, The position of the groove is arranged according to the scope of the groove, and multiple groups of upward vertical cutting holes are arranged to control the groove area. The adjacent cutting holes are independent of each other and affect each other. Each group of cutting holes is divided into charging holes and holes that provide compensation space. Empty holes, the first-blast charging holes mainly use the compensation space provided b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com