Machine vision-based workpiece defect detection method

A defect detection and machine vision technology, which is applied in the direction of optical defect/defect detection, can solve the problems of inability to meet the real-time detection of workpiece surface defects, poor segmentation effect, etc., and achieve effective detection, good adaptability, and high detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

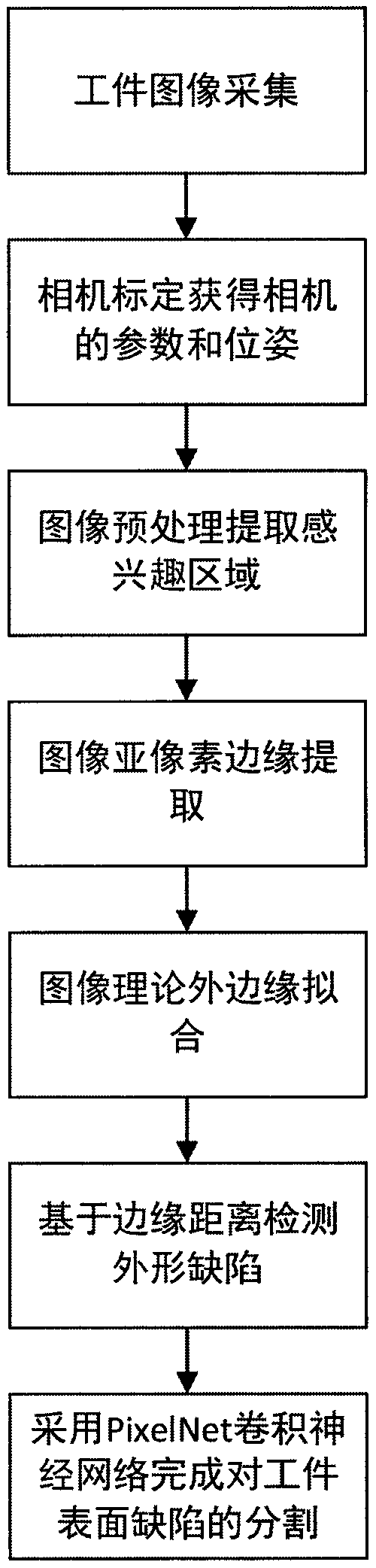

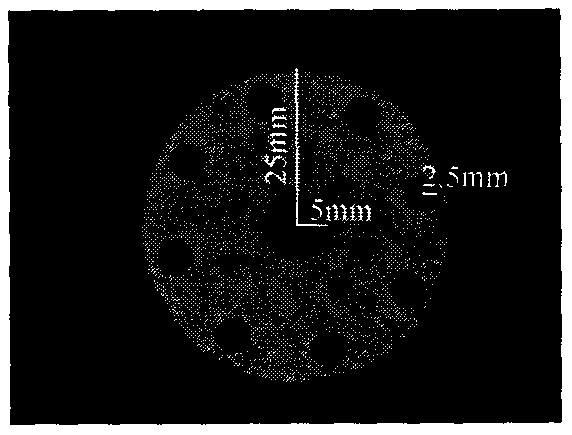

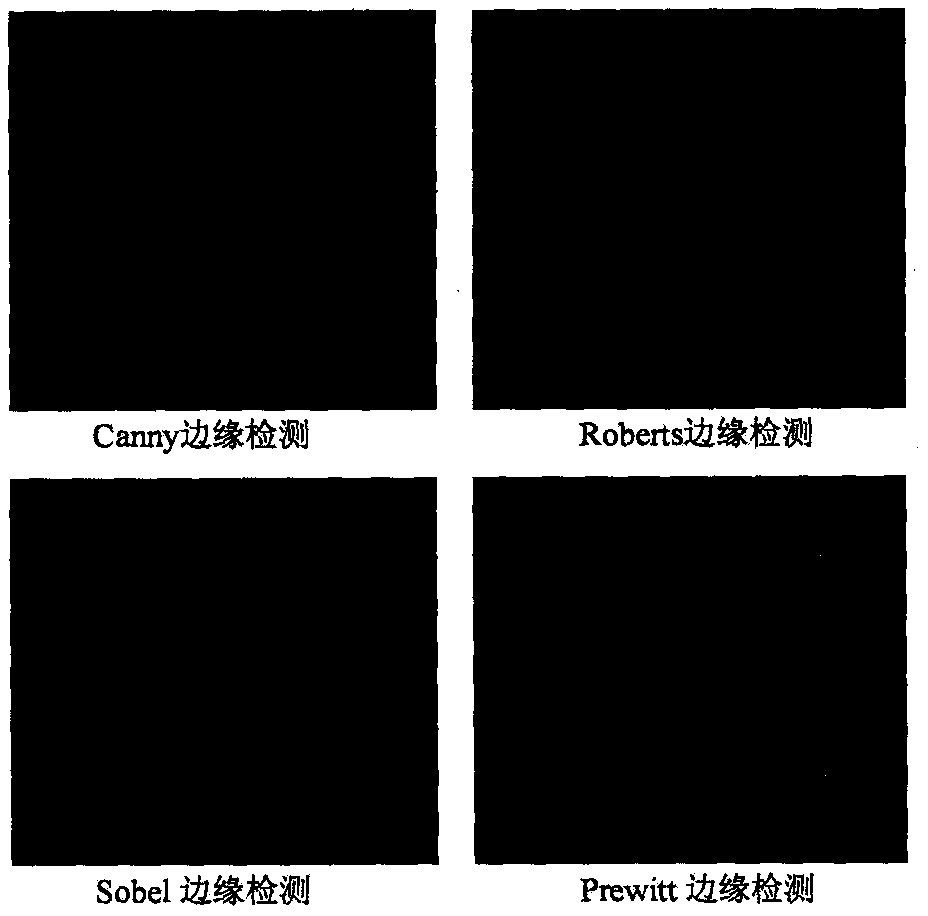

[0026] The overall framework flow diagram of the present invention is as figure 1 shown. First, collect the image of the flange plate workpiece, use the Zhang calibration method to calibrate the camera, and then correct the distortion of the workpiece image; then use the Gaussian filter to smooth the image, using a 5×5 Gaussian with a standard deviation of 1 The kernel performs convolution operation to extract the region of interest; the Canny algorithm, Sobel algorithm, Roberts algorithm and Prewitt algorithm are used to detect the pixel-level edge of the image, and the detection results of various algorithms are compared, and the Canny algorithm with the best extraction effect is selected; The sub-pixel edge detection algorithm based on the gray moment extracts the sub-pixel edge of the workpiece image; finally, the circle fitting method is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com