Device for preventing haze and ultraviolet coating of optical lens

An optical lens, anti-ultraviolet technology, applied to the device, coating and other directions of coating liquid on the surface, can solve the problems of lens damage and complicated process, and achieve the effect of avoiding lens damage, simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

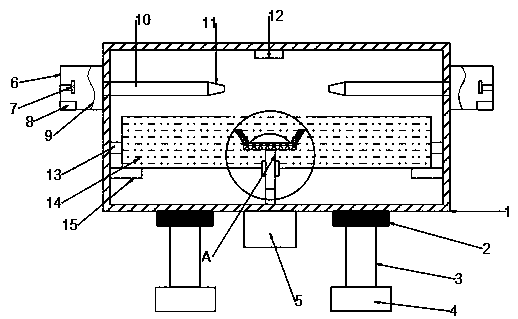

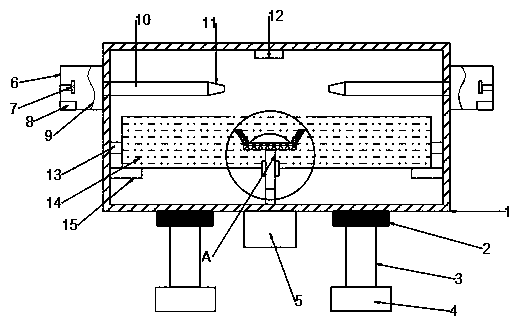

[0023] see Figure 1~2 , in an embodiment of the present invention, a device for performing anti-fog and anti-ultraviolet coating on optical lenses, including a housing 1, support legs 3, a fan box 6, an air outlet pipe 10 and an air outlet 11, the housing 1 The bottom of the rubber pad 2 is provided with a number of rubber pads 2, and the inside of the rubber pad 2 is filled with foam cushioning material, which acts as a buffer protection device. The bottom of the rubber pad 2 is fixedly connected to the upper end of the support leg 3, and the lower end of the support leg 3 is connected to the support The block 4 is fixedly connected, and the rubber pad 2, the support leg 3 and the support block 4 cooperate with each other to support the device.

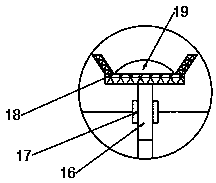

[0024] A hydraulic cylinder 5 is arranged in the middle of the bottom of the housing 1, the output shaft of the hydraulic cylinder 5 runs through the bottom of the housing 1 and is connected with the rotating rod 16, the rotating ro...

Embodiment 2

[0028] A device for processing optical lenses, including the device described in Embodiment 1 for performing anti-fog and anti-ultraviolet coatings on optical lenses.

[0029] The working principle of the present invention is: the inside of the fan box 6 is provided with a fan 7, the lower end of the fan 7 is provided with a power supply 8, the power supply 8 is used to supply power for the fan 7 and the heating wire 9, and one side of the fan box 6 is connected to the air outlet. The pipes 10 are connected, and the air outlet pipe 10 runs through the left and right walls of the housing 1. The two air outlet pipes 10 are provided with an air outlet 11 at one end close to each other. The hydraulic cylinder 5 controls the rotation rod 16 to expand and contract up and down, and drives the storage plate 18. Move up and down, and because the storage plate 18 is provided with some mesh holes, the bottom of the lens 19 can also touch the anti-ultraviolet solution, and when the hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com