Preparation method of terephthalic acid type UPR (unsaturated polyester resin)

A technology of terephthalic acid and polyester resin, applied in the field of preparation of unsaturated polyester resin, can solve the problems of poor wettability, limit the use range of unsaturated polyester resin, etc., and achieve good wettability and good chemical resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method of terephthalic acid type unsaturated polyester resin, comprises the following steps:

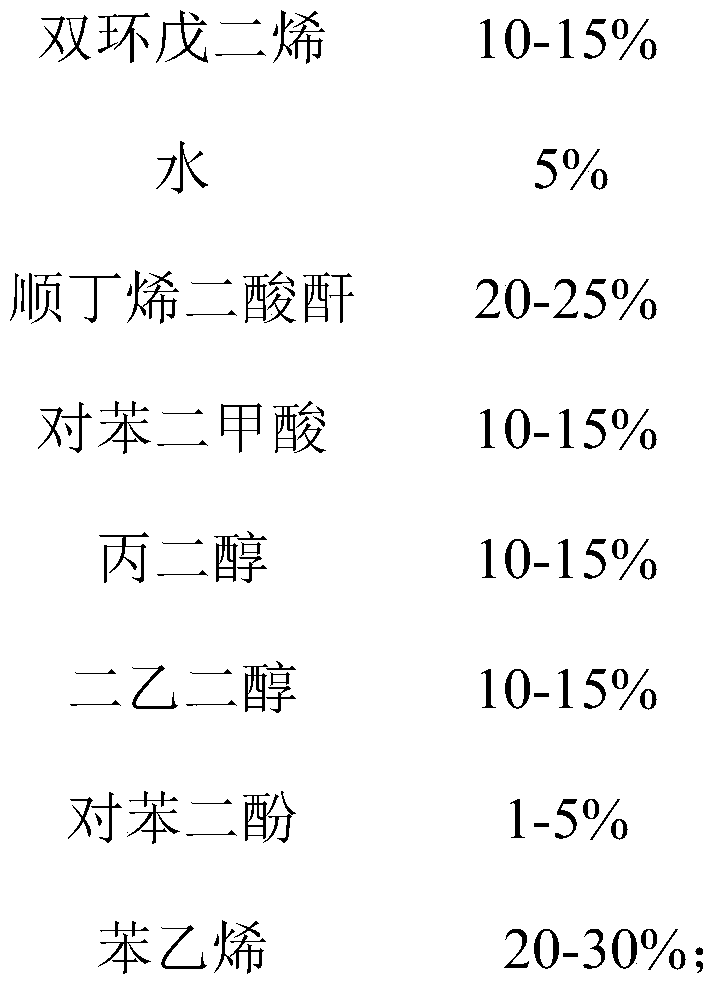

[0025] (1) Prepare raw materials according to the following mass percentages:

[0026]

[0027] (2) Under the protection of nitrogen, add maleic anhydride and water into the reaction kettle, raise the temperature to 110°C and stir until the maleic anhydride is completely dissolved, add dicyclopentadiene dropwise, after the dropwise addition, heat up To 130°C, react for 2h;

[0028] (3) In another reaction kettle, add terephthalic acid, propylene glycol and a catalyst, heat up to 220°C, and react until the acid value is lower than 5mgKOH / g;

[0029] The catalyst uses tungsten hexachloride as the main catalyst and the reducing aluminum compound as the co-catalyst. The tungsten hexachloride is modified to introduce oxygen ligands and phenolic ligands to form a complex WOCl 4-x (OAr) X .

[0030] By reacting with water in the emulsion, oxygen ligands a...

Embodiment 2

[0049] A kind of preparation method of terephthalic acid type unsaturated polyester resin, comprises the following steps:

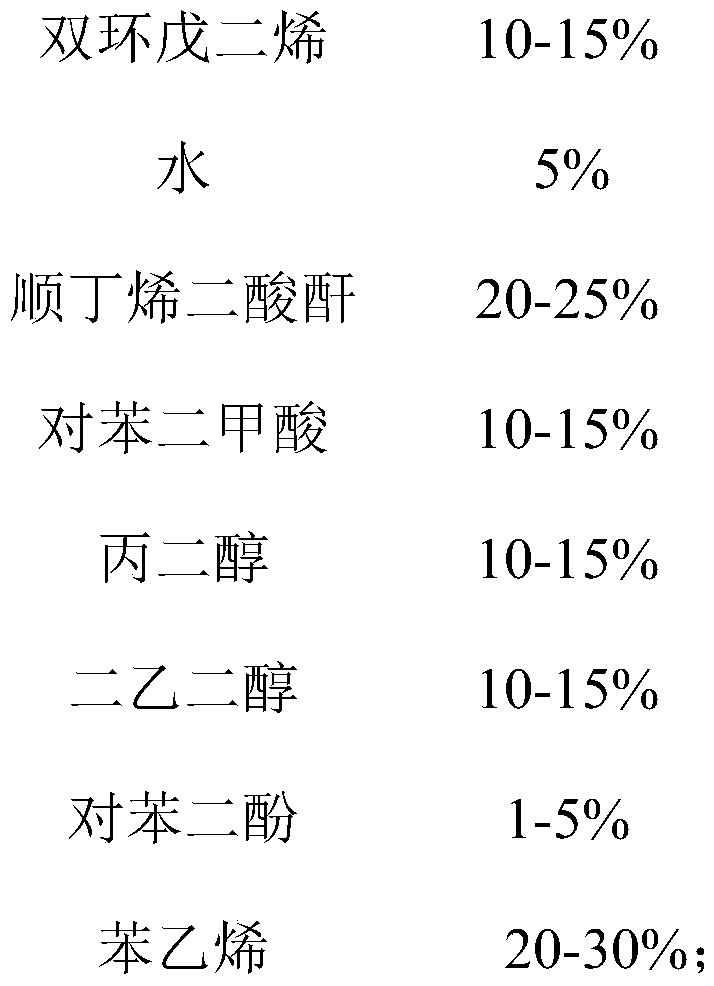

[0050] (1) Prepare raw materials according to the following mass percentages:

[0051]

[0052]

[0053] (2) Under the protection of nitrogen, add maleic anhydride and water into the reaction kettle, raise the temperature to 120°C and stir until the maleic anhydride is completely dissolved, add dicyclopentadiene dropwise, after the dropwise addition, heat up To 140°C, react for 3h;

[0054] (3) In another reaction kettle, add terephthalic acid, propylene glycol and a catalyst, heat up to 230°C, and react until the acid value is lower than 5mgKOH / g;

[0055]The catalyst uses tungsten hexachloride as the main catalyst and the reducing aluminum compound as the co-catalyst. The tungsten hexachloride is modified to introduce oxygen ligands and phenolic ligands to form a complex WOCl 4-x (OAr) X .

[0056] By reacting with water in the emulsion, oxyge...

Embodiment 3

[0065] A kind of preparation method of terephthalic acid type unsaturated polyester resin, comprises the following steps:

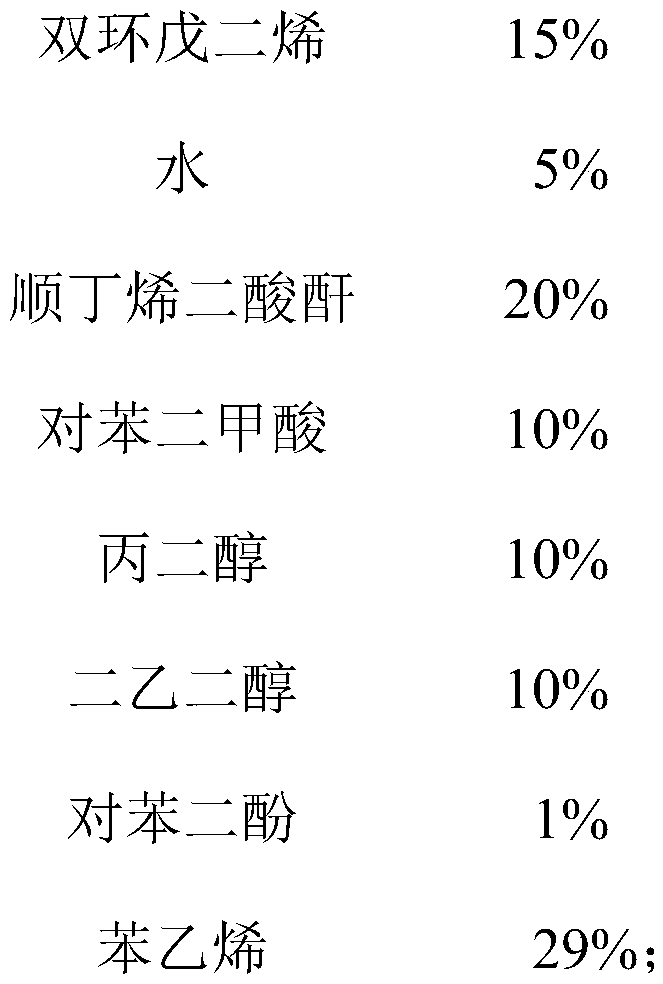

[0066] (1) Prepare raw materials according to the following mass percentages:

[0067]

[0068] (2) Under the protection of nitrogen, add maleic anhydride and water into the reaction kettle, raise the temperature to 115°C and stir until the maleic anhydride is completely dissolved, add dicyclopentadiene dropwise, after the dropwise addition, heat up To 135°C, react for 2.5h;

[0069] (3) In another reaction kettle, add terephthalic acid, propylene glycol and a catalyst, heat up to 225°C, and react until the acid value is lower than 5mgKOH / g;

[0070] The catalyst uses tungsten hexachloride as the main catalyst and the reducing aluminum compound as the co-catalyst. The tungsten hexachloride is modified to introduce oxygen ligands and phenolic ligands to form a complex WOCl 4-x (OAr) X .

[0071] By reacting with water in the emulsion, oxygen ligands...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap