Rotary seal loading process and device for minor repair work

A technology of rotary sealing and loading device, applied in the directions of sealing/isolation, rotary drilling, rotary drilling rig, etc., can solve the problems of inability to carry out construction under pressure, inability to apply WOB, heavy maintenance workload, etc., to solve the problem of overhaul High cost, reduced operation cost and fast tripping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

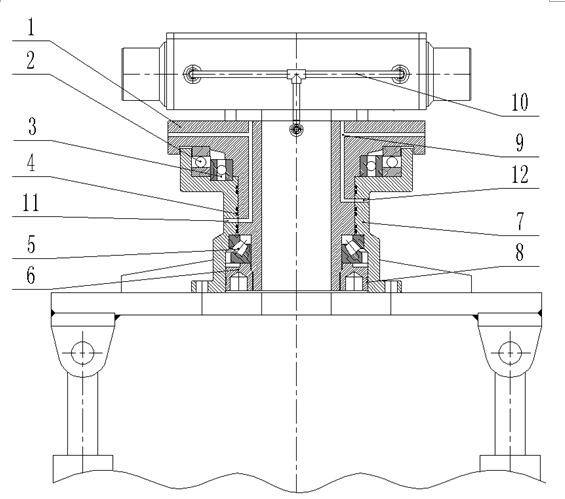

[0016] The detailed description and technical content of the present invention are described below in conjunction with the accompanying drawings. However, the accompanying drawings are only for reference and description, and are not intended to limit the present invention.

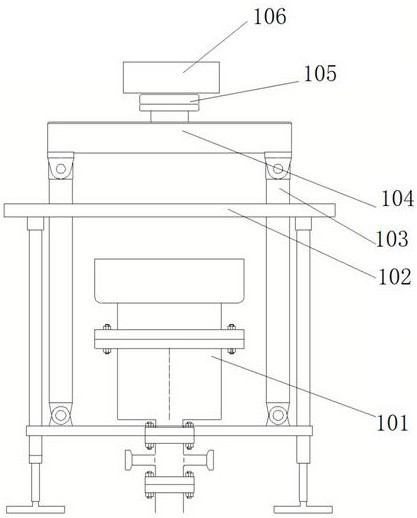

[0017] as attached figure 1 As shown in the figure, the rotary seal loading device for minor repair operations includes a rotary sealer 101, a platform 102, a lifting cylinder 103, and a rotary clamp. The rotary sealer is connected with the casing spool at the wellhead, and the platform is fixed to the ground. The lower part of the lifting cylinder is connected to the platform, and the rotating clamp is connected to the upper part of the lifting cylinder. The casing spool is connected to the platform.

[0018] The rotary card holder includes a rotary card holder slip 106, a slip drive device, a rotary card holder turntable 105, and a rotary card holder fixing seat 104. The upper end of the rotary card hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com