Mixed grouting machine used for tunnel construction and capable of removing concrete gas through choking pressing

A technology for tunnel construction and concrete, which is used in tunnels, tunnel linings, and earth-moving drilling and mining, etc., can solve the problems of affecting the filling effect, difficulty in filling, and premature condensation, and achieve the effect of removing internal gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

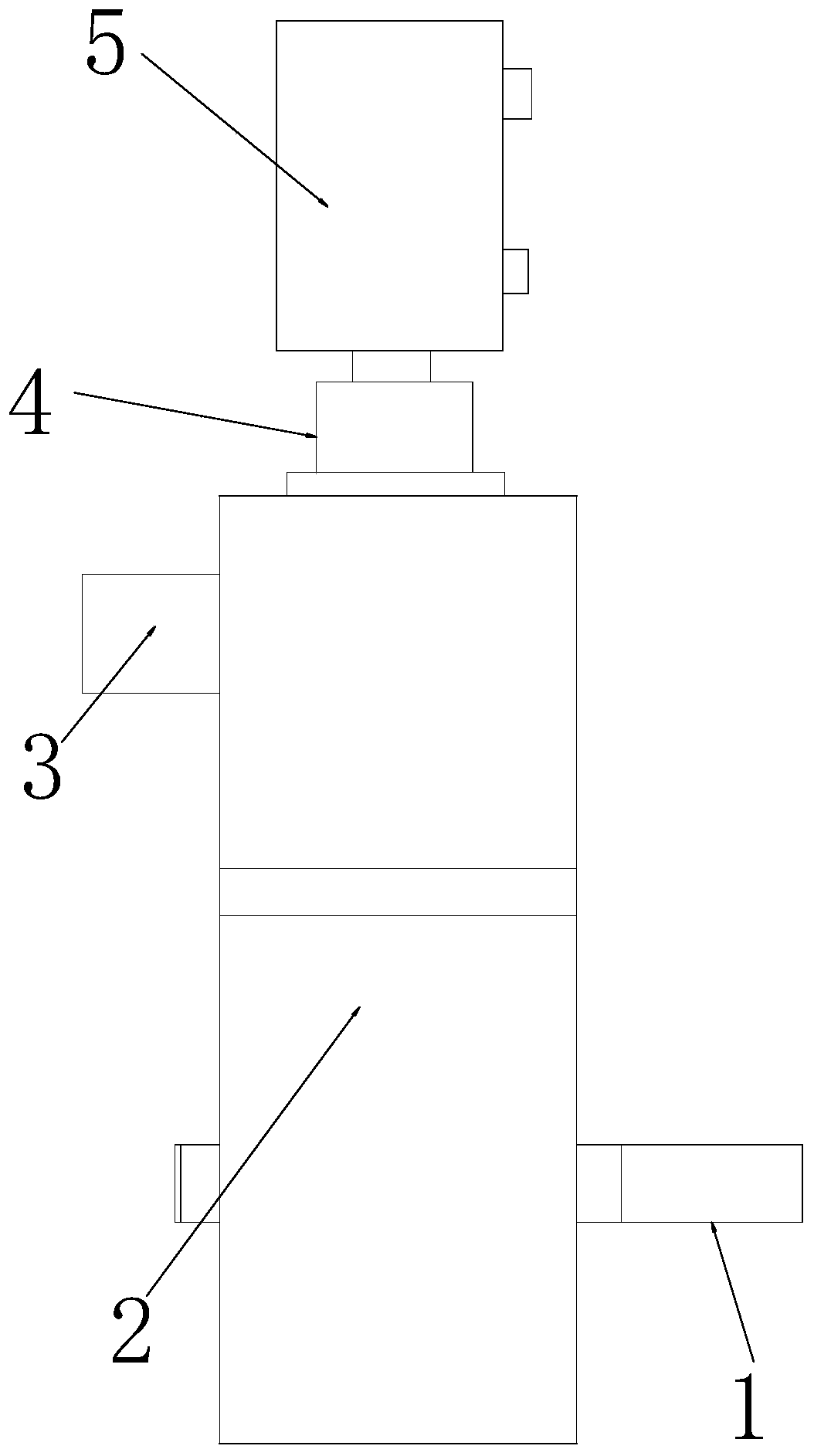

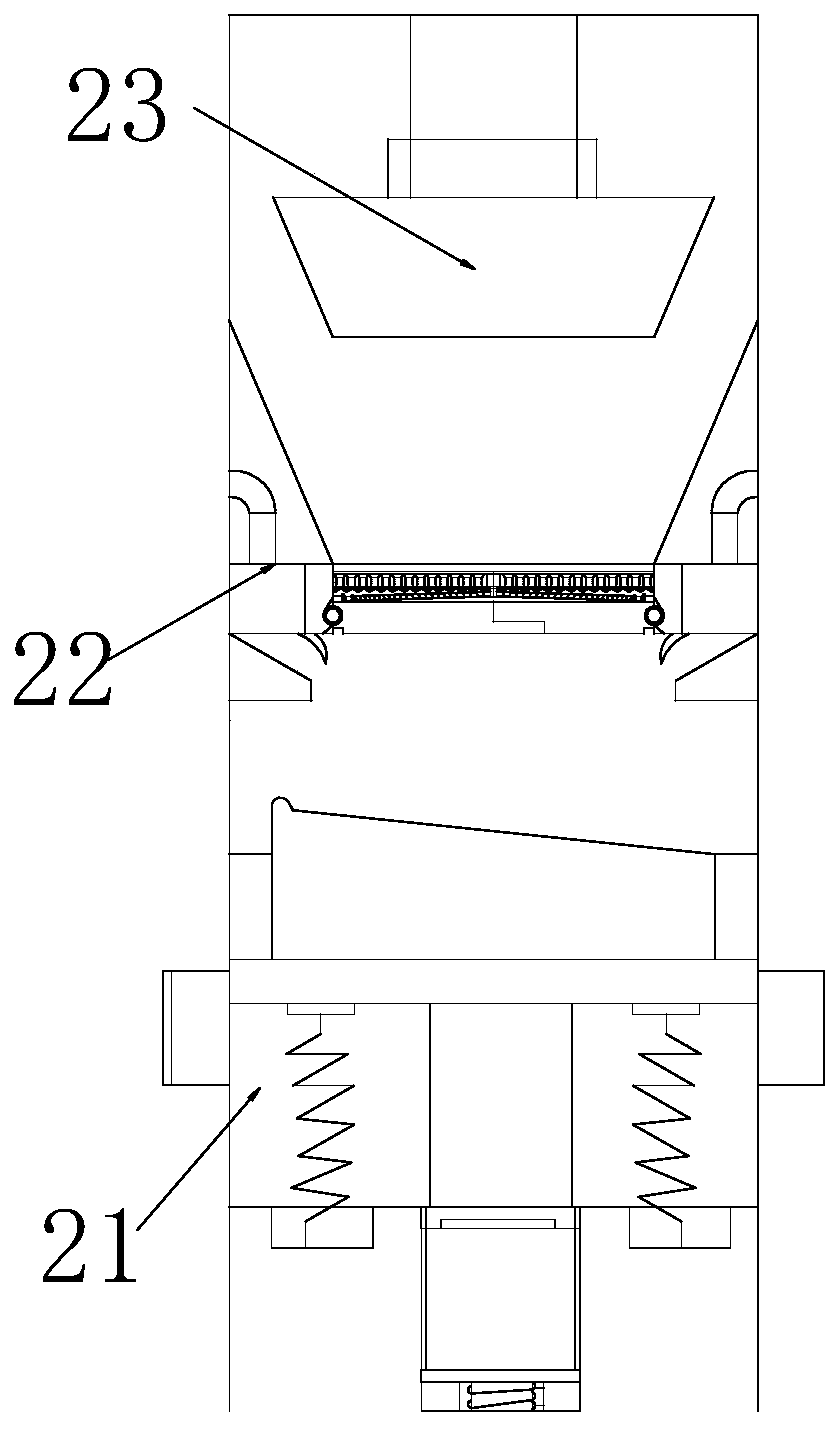

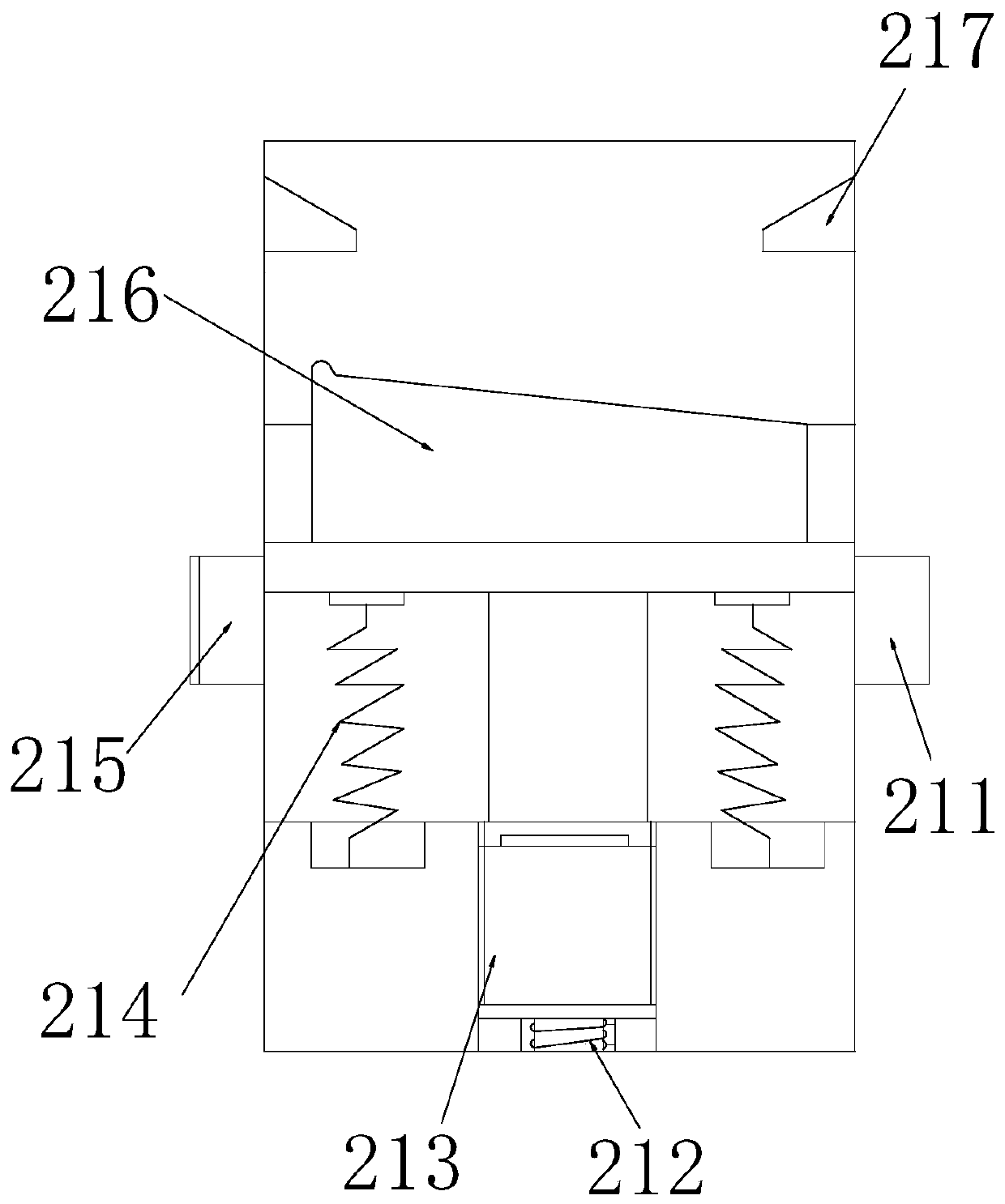

[0027] see figure 1 , the present invention provides a mixing grouting machine for tunnel construction that removes concrete gas through blocking and pressing, and its structure includes: an output pipe 1, a movable mixing device 2, an input pipe 3, a bearing seat 4, an air pressure frame 5, and the bearing seat 4 is arranged on the upper end surface of the movable mixing device 2 and is fixedly connected with the movable mixing device 2, the air pressure frame 5 is embedded in the inside of the bearing seat 4 and is movably connected with the inside of the bearing seat 4, and the output pipe 1 is arranged on The right end surface of the movable mixing device 2 is connected through the two, the input pipe 3 is located at the left end surface of the movable mixing device 2 and is mechanically connected with the movable mixing device 2, and the inside of the bearing seat 4 is provided with a ball movable frame, through which The internal ball structure can slow down the equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com