LED (Light-Emitting Diode) spotlight convenient to mount and debug

An LED spotlight, installation and debugging technology, applied in the parts of the lighting device, the loss prevention measures of the lighting device, the lighting device, etc. Spotlight assembly efficiency and other issues, to achieve the effect of shortening packaging time, easy overall packaging, convenient space arrangement and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

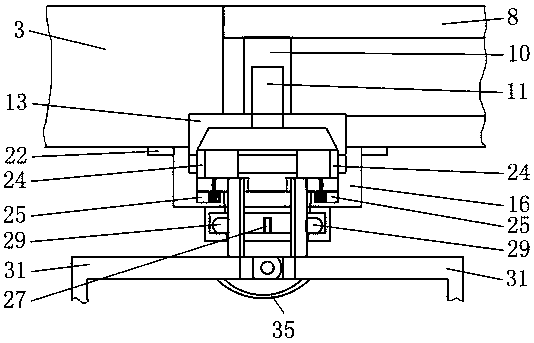

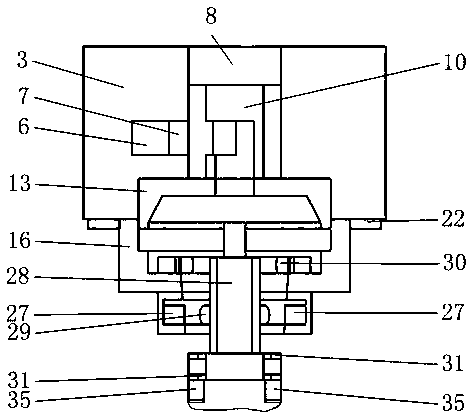

[0052] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

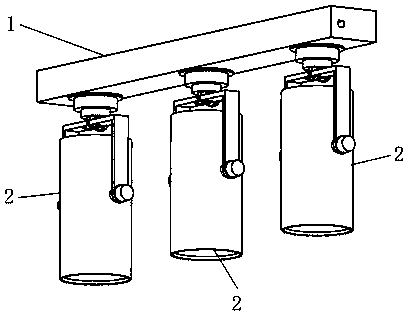

[0053] Such as figure 1 As shown, it includes a lamp stand mechanism 1 and a spotlight mechanism 2, wherein several spotlight mechanisms 2 are suspended and installed on the lamp stand mechanism 1 in a straight line at equal intervals.

[0054] Such as Figure 4 , 5 As shown, the above-mentioned lamp holder mechanism 1 includes a horizontal frame 3, a pressure plate 8, a first return leaf spring 9, a push rod 10, and an unlocking sleeve 13, wherein as Figure 5 , 8 As shown, a pressure plate 8 is embedded in the pressure groove 4 on the upper end surface of the cross frame 3; as Figure 4 , 6 , 7, unlocking sleeves 13 are installed in some circular grooves 5 that are evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com