Optical vortex optical fiber current sensor based on single slit detection

A fiber optic current and sensor technology, which is applied in the measurement of current/voltage, measurement of electrical variables, and voltage/current isolation, etc. problem, to achieve the effect of low cost, reliable detection and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention are described as follows in conjunction with the accompanying drawings:

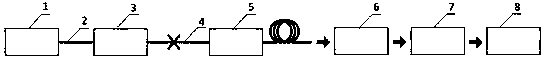

[0019] see figure 1 , an optical vortex fiber optic current sensor based on single-slit detection, including a linearly polarized laser 1, a single-mode fiber 2, a polarization controller 3, an optical vortex fiber 4, a fiber grating 5, a linear polarizer 6, and a single-slit diaphragm 7 and light detector 8 . The linearly polarized light emitted by the linearly polarized laser 1 passes through the single-mode optical fiber 2 and passes through the polarization controller 3, then outputs polarized light with an adjustable polarization state, and is fused with the optical vortex optical fiber 4, and the light is in the middle of the optical vortex optical fiber 4 core transmission.

[0020] The end face photomicrograph of optical vortex fiber 4 can be found in figure 2 , this vortex fiber is a triple-clad fiber, from the inside to the outside are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com