Plug-in assembly

A component and plug-in direction technology, which is applied to the parts, connections, and electrical components of the connecting device, can solve problems such as interference, increasing the height of the socket protruding from the outer surface of the appliance, and affecting the appearance of the circuit board, optical equipment, etc. , to avoid interference and reduce the total length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

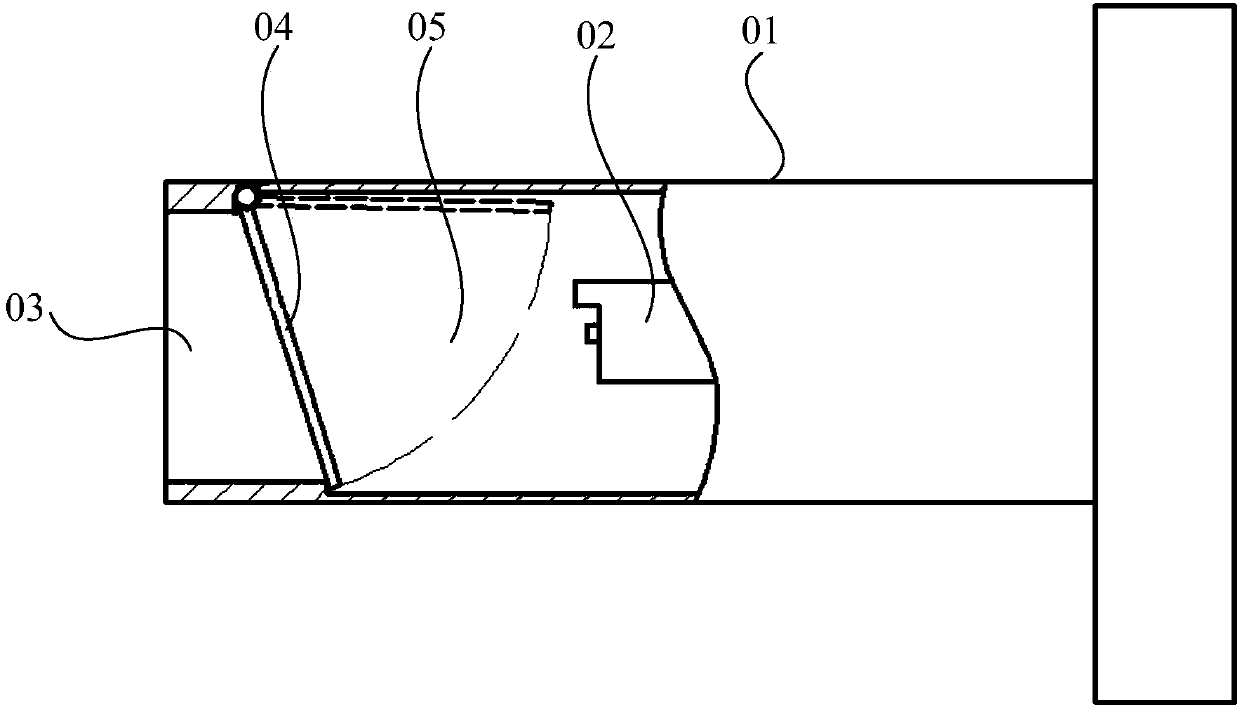

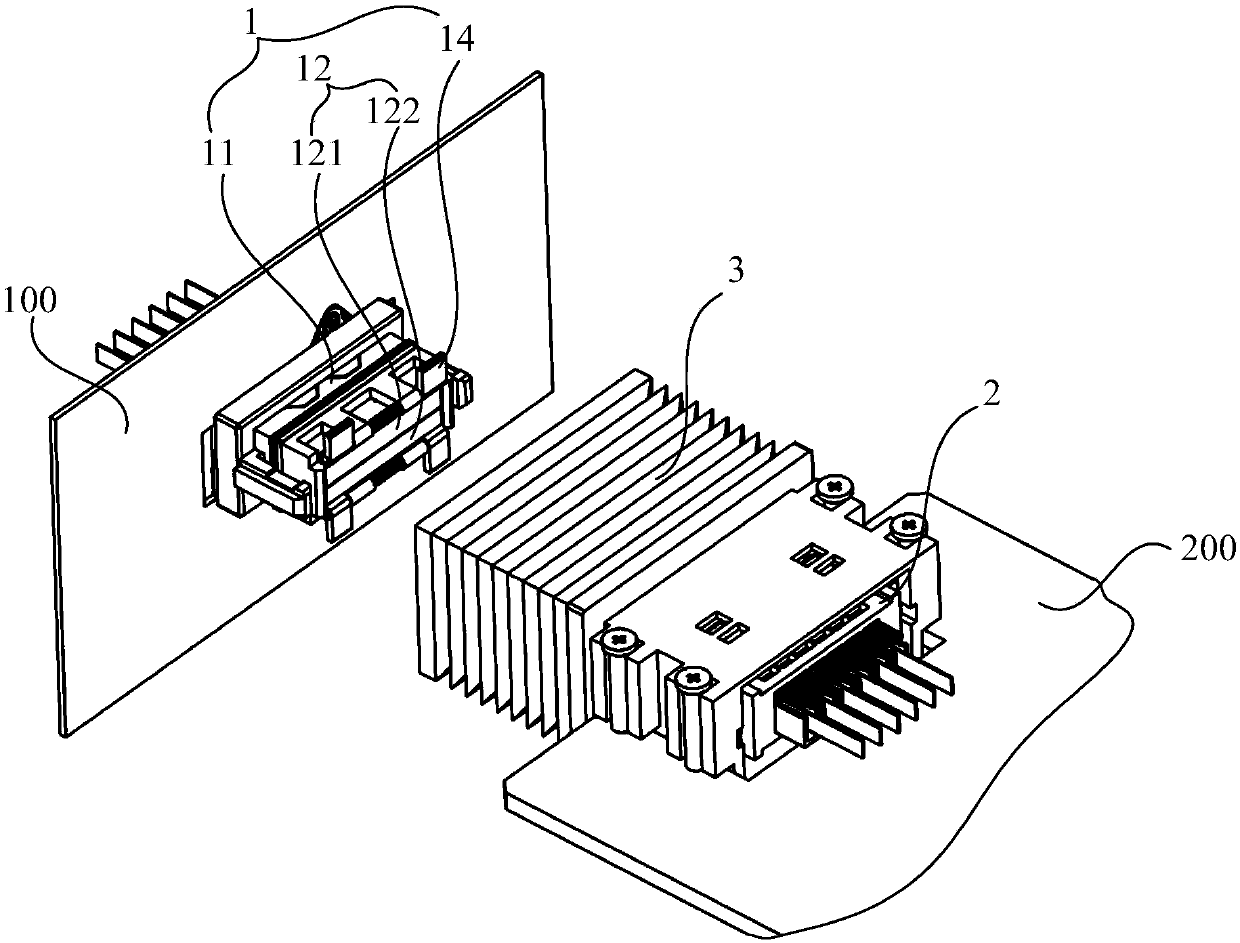

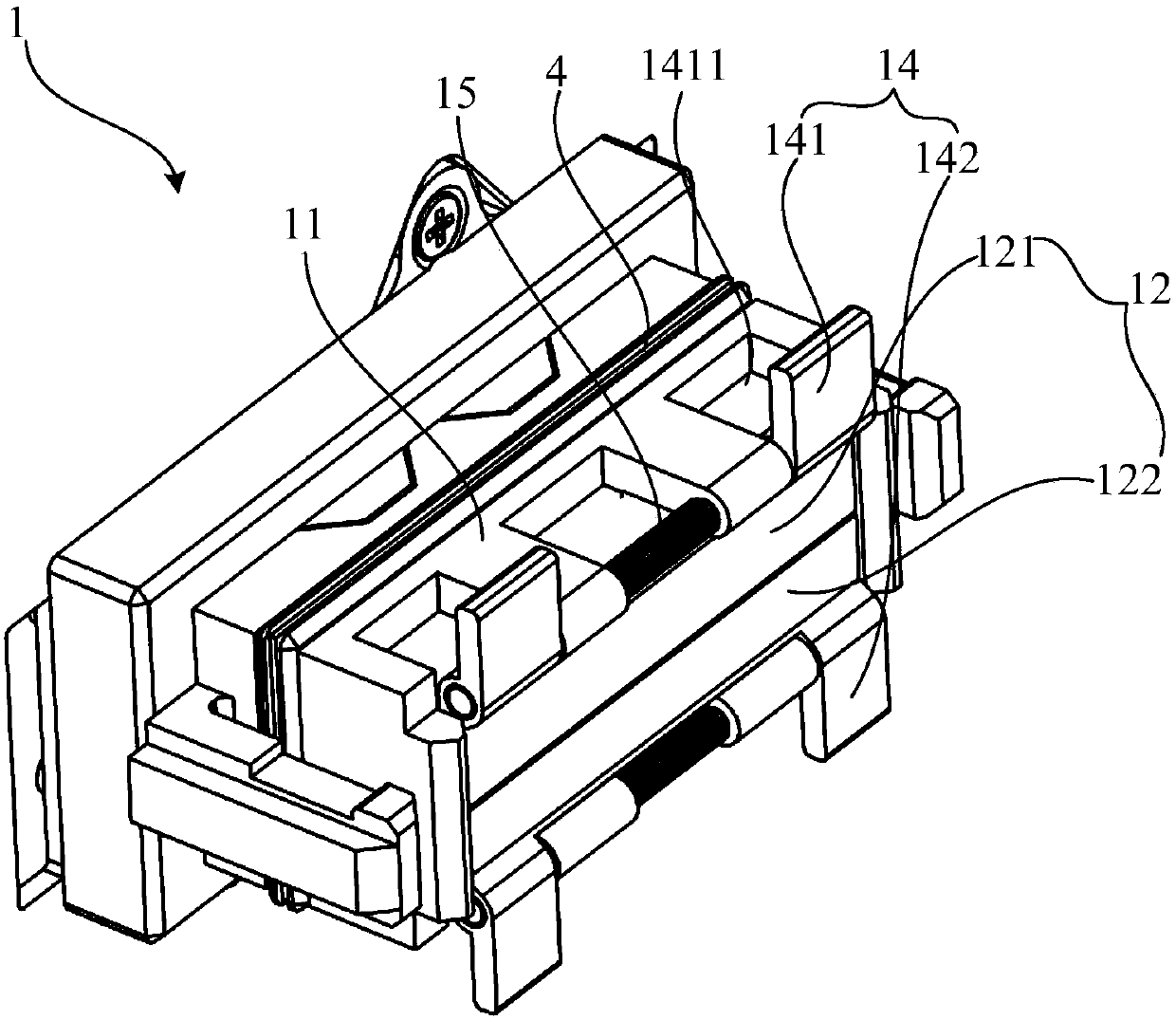

[0067] Such as image 3 As shown, one end of the door opening handle 14 is connected to the first end of the first dustproof door 12, and the other end extends radially outward along the socket 13 and out of the socket housing 11, as Figure 7 As shown, the pusher 22 extends along the insertion direction of the plug 2, and along the insertion direction of the plug 2, the front end of the pusher 22 protrudes from the front end of the first ferrule 21, and the inner side of the pusher 22 forms an escape space 23, The avoidance space 23 is located between the front end of the pusher 22 and the front end of the first ferrule 21, and an accommodation gap 24 is formed between the side wall of the front end of the first ferrule 21 and the pusher 22, and the accommodation gap 24 communicates with the avoidance space 23 ,Such as Figure 4 As shown, the first dustproof door 12 also includes a second end b opposite to the first end a, as Figure 8 As shown, in the process of moving the...

Embodiment 2

[0082] Such as Figure 29 As shown, the first end of the first dust-proof door 12 is connected to one end of the connecting rod 17, and the other end of the connecting rod 17 is hinged to the middle part of the socket housing 11 through the rotating shaft 18. The door opening handle 14 is a roller-shaped structure, and the roller One end of the structure is connected to the side of the first end of the first dust-proof door 12, and the other end extends outwards along the extension direction parallel to the rotating shaft 18 and out of the socket housing 11, as Figure 30 As shown, the pusher 22 is a fin structure extending along the insertion direction of the plug 2. Along the insertion direction of the plug 2, the front end of the fin structure forms a beveled edge, and the beveled edge is located at the front end of the first ferrule 21. On the front side, an avoidance space 23 is formed on the inner side of the fin structure. The avoidance space 23 is located between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com