Door handle system for a motor vehicle

A technology for door handles and automobiles, applied in the field of door handle systems, can solve problems such as large working space, increased manufacturing costs, and easy wear and tear, and achieve the effect of compact structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

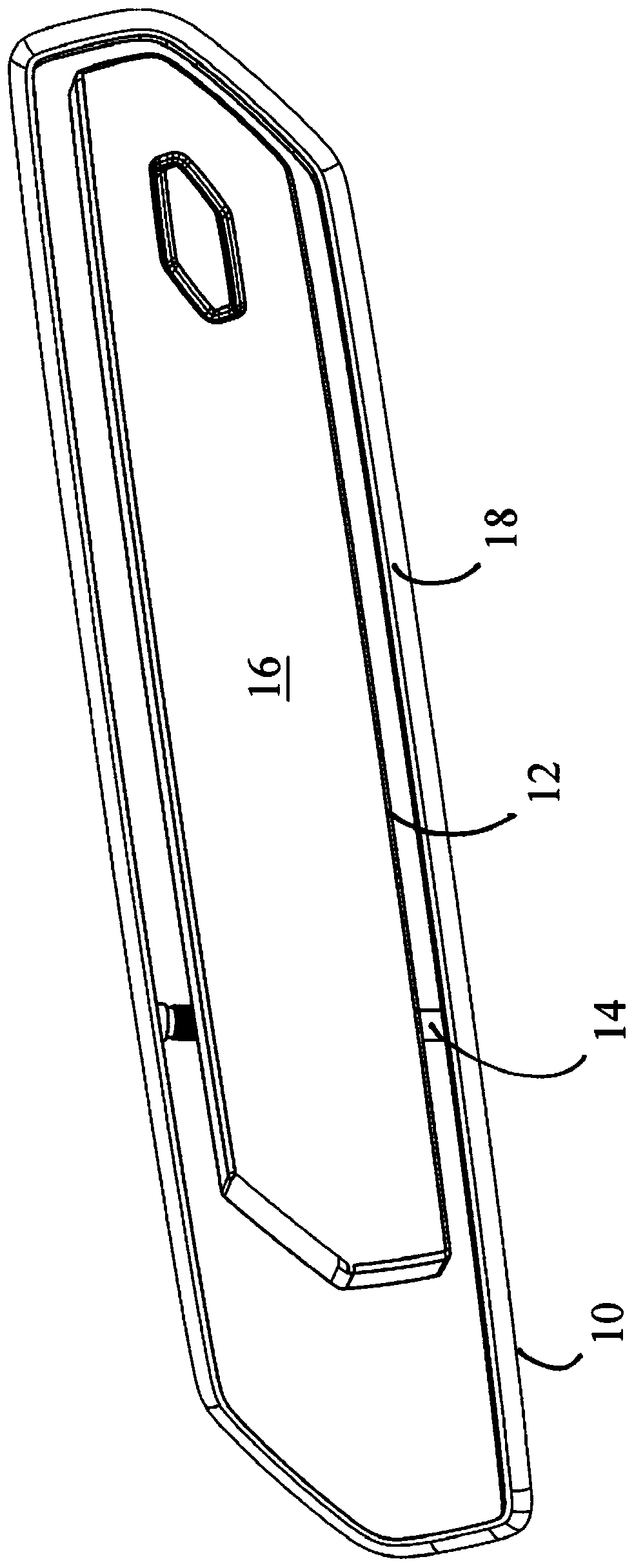

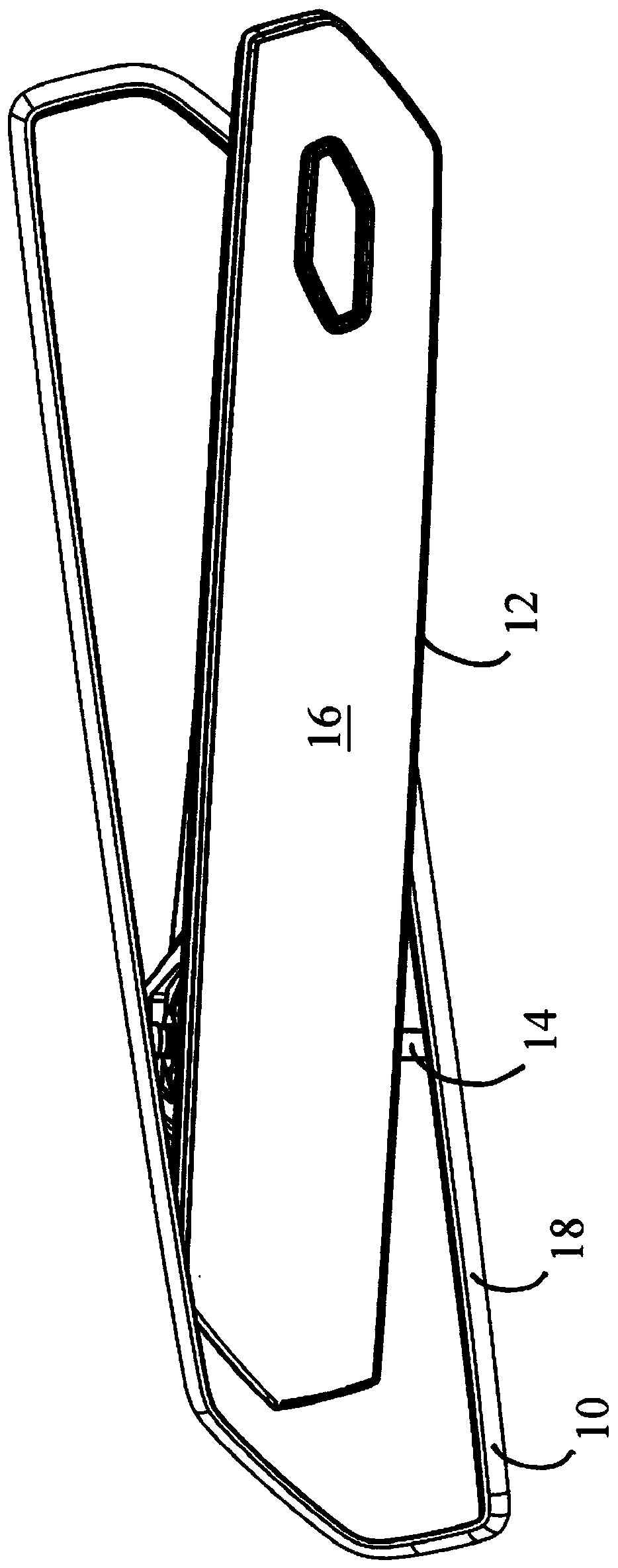

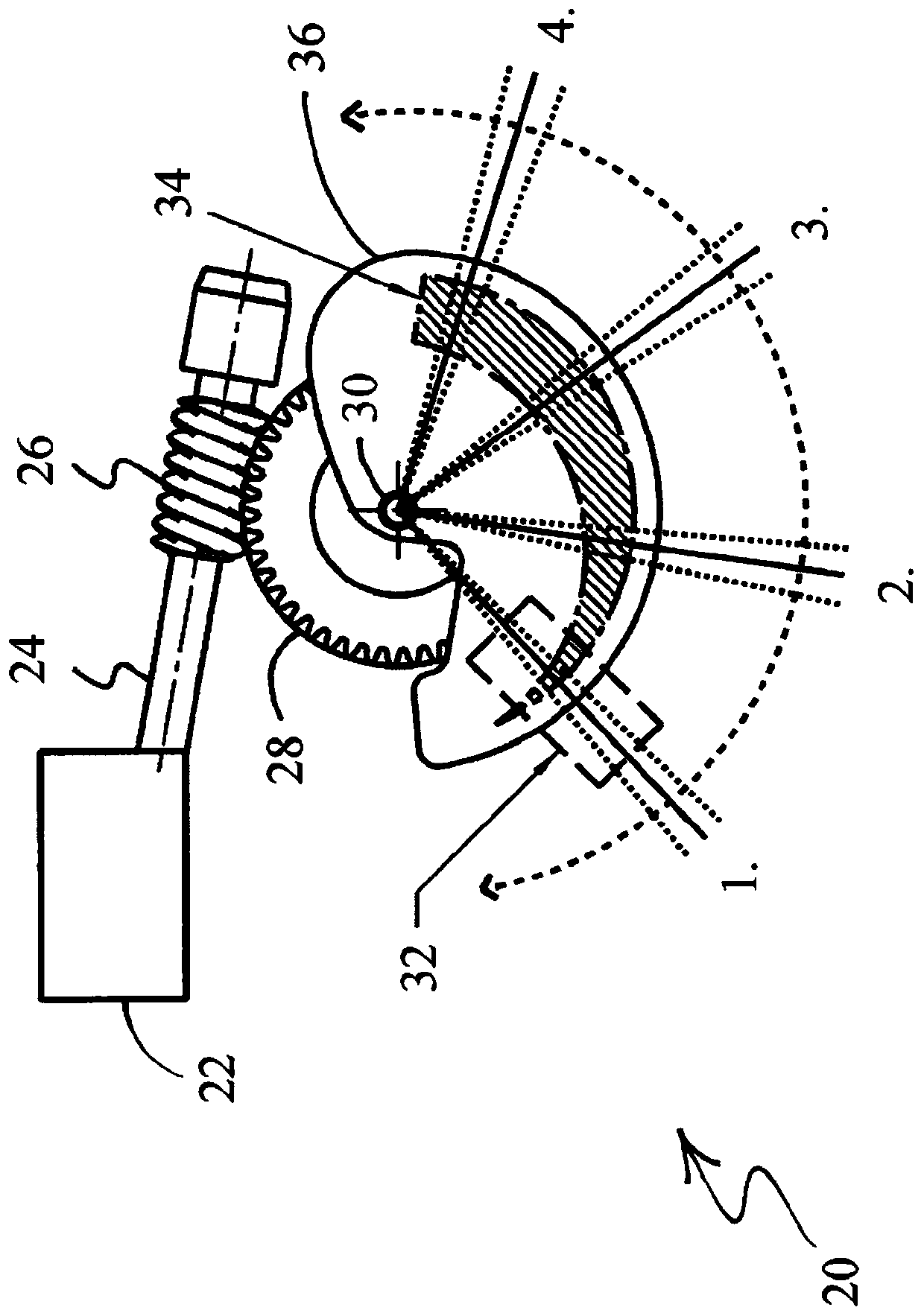

[0024] figure 1 A door handle system for a car is shown. In particular, the door handle system is suitable for fitting into a door, in particular the left side door of a motor vehicle. The door handle system comprises a fastening frame 10 and a handle part 12 , in the exemplary embodiment also an outside door handle, which is pivotably supported on the fastening frame 10 . In particular, the handle portion 12 is pivotable about a deflection axis 14 , which in the present embodiment is oriented substantially vertically. figure 1 The handle portion 12 is shown in a rest orientation in which it is fully received within the fixed bracket 10 such that the outer surface 16 of the handle portion 12 is generally flush with the outer edge 18 of the fixed bracket.

[0025] This means that the outer surface 16 of the handle part 12 in the rest position is flush with the outer panel of the vehicle when the fastening bracket 10 is inserted aligned in the outer panel of the vehicle.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com