Compound feed and feed additive for reducing limb disease in sows and preparation method thereof

A technology for additive preparation and compound feed, which is applied in the preservation method of animal feed raw materials, the molding or processing of animal feed, and animal feed, etc. It has the effect of prolonging digestion and absorption time, stimulating appetite, and avoiding fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

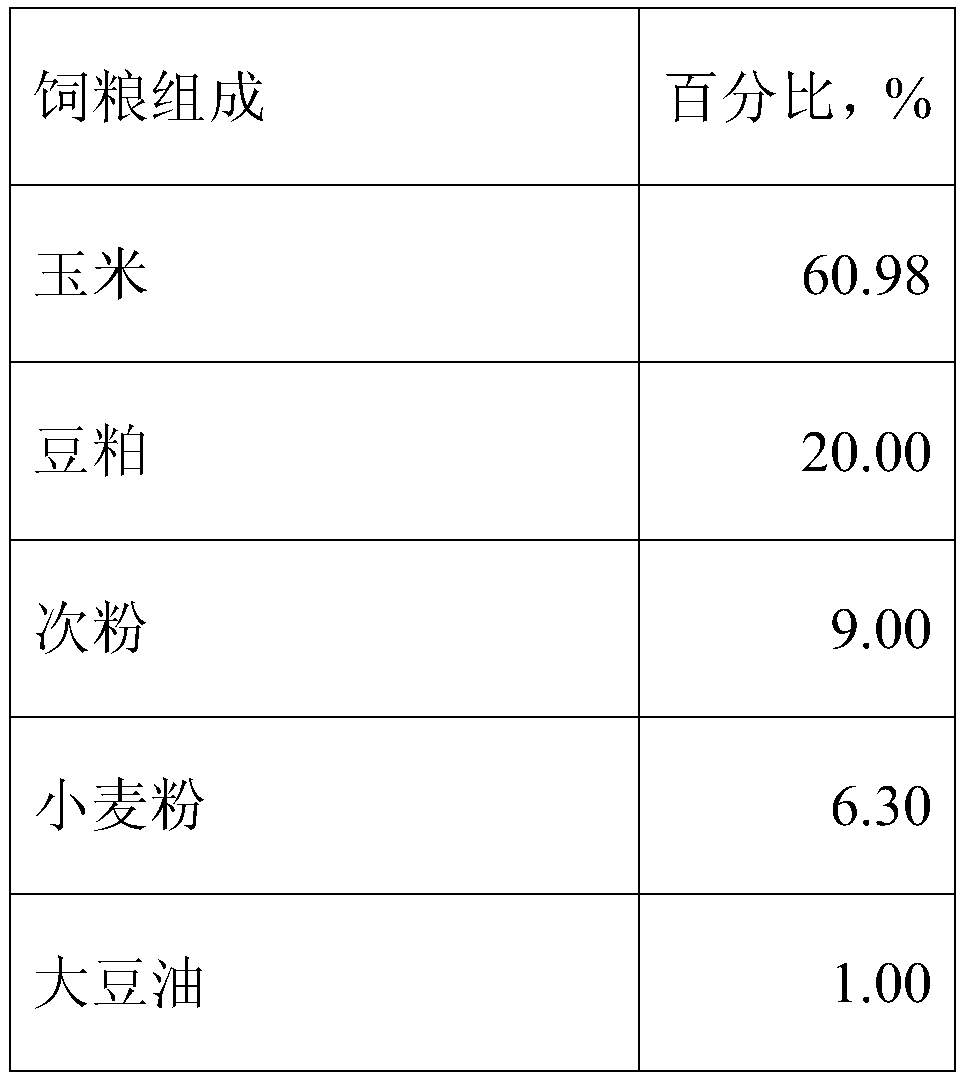

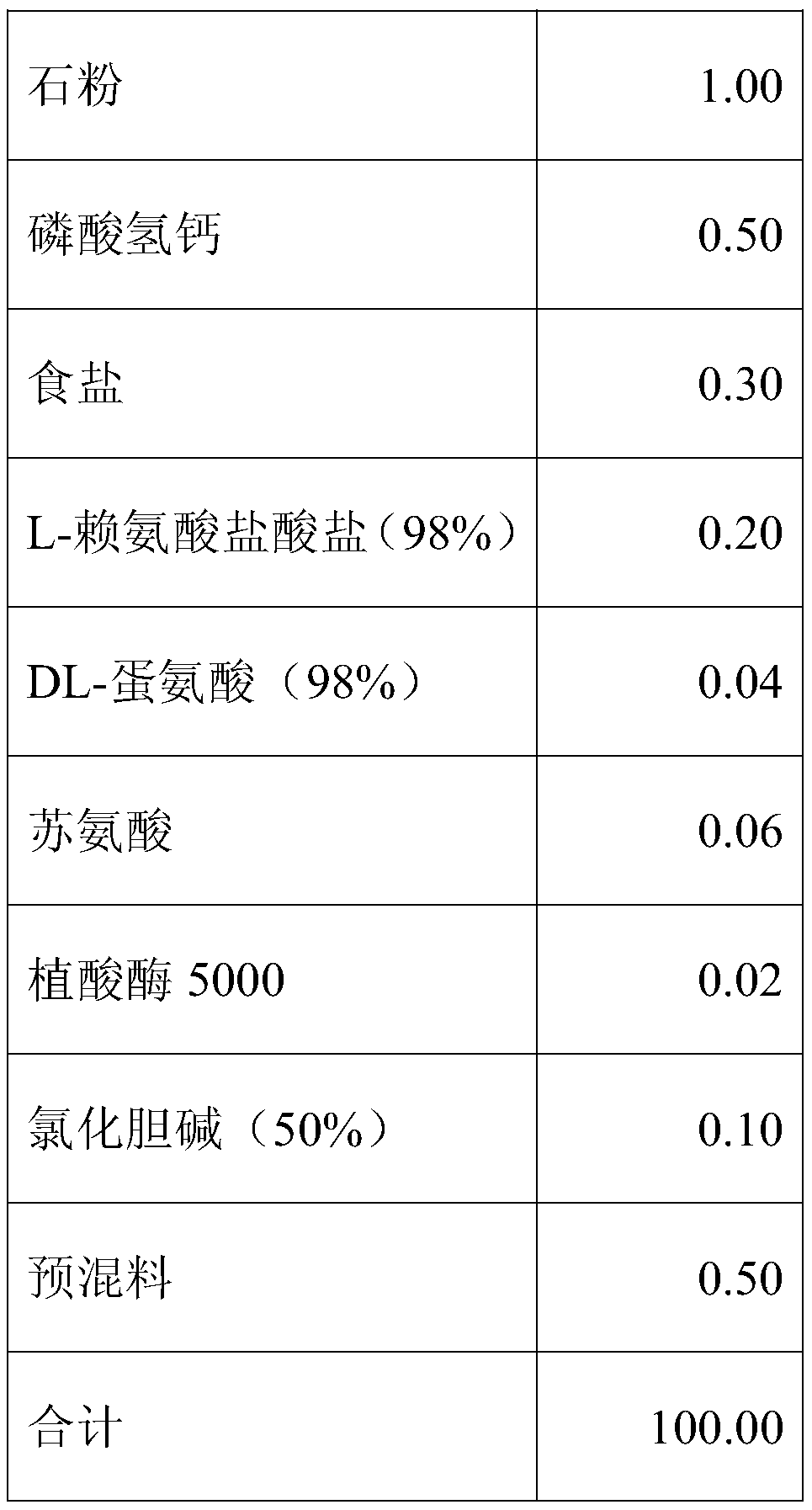

Image

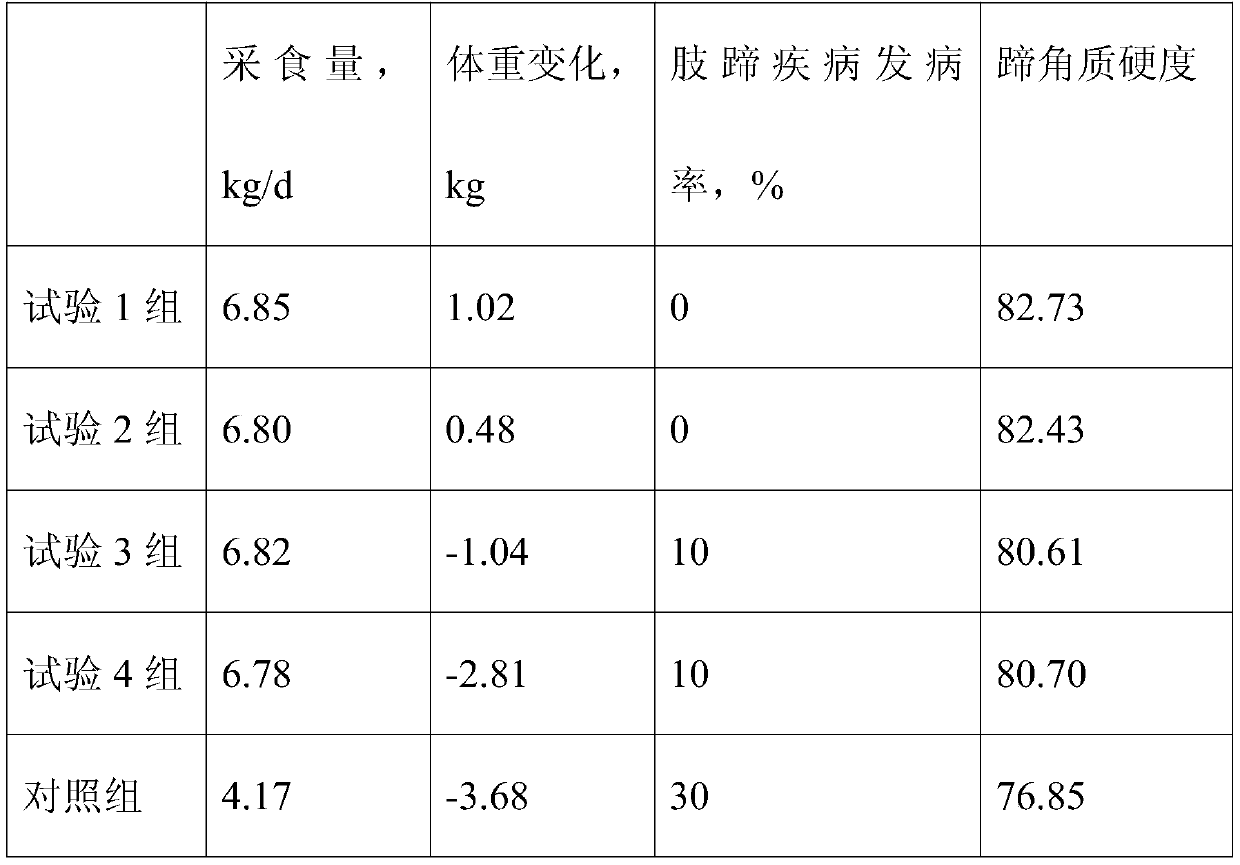

Examples

Embodiment 1

[0042] A method for preparing a compound feed additive for reducing limb and hoof diseases in sows, comprising the steps of:

[0043] S1. Sinter the dried rice husks in an oxygen-free environment for 40 minutes at a sintering temperature of 280° C. to form partially carbonized rice husks; then add 100 kg of partially carbonized rice husks to the compound enzyme preparation for enzymolysis for 12 hours at a temperature of 38° C. The water content of the compound enzyme preparation is 50wt%, the specific activity of the compound enzyme preparation is 7500-12500U / g, and the compound enzyme preparation is composed of protease, amylase, cellulase and pectinase in a material ratio of 2:4:10 : 2 components, taken out and drained, then added to the composite trace element aqueous solution and soaked for 12 hours, freeze-dried, pulverized, then added 4kg calcium dihydrogen phosphate and 14kg calcium lactate and mixed evenly to obtain the first material;

[0044] The above compound trac...

Embodiment 2

[0047] A method for preparing a compound feed additive for reducing limb and hoof diseases in sows, comprising the steps of:

[0048] S1. Sinter the dried rice husks in an oxygen-free environment for 60 minutes at a sintering temperature of 260° C. to form partially carbonized rice husks; then add 100 kg of partially carbonized rice husks to the compound enzyme preparation for enzymolysis for 24 hours at a temperature of 35° C. The water content of the compound enzyme preparation is 70wt%, the specific activity of the compound enzyme preparation is 7500-12500U / g, and the compound enzyme preparation is composed of protease, amylase, cellulase and pectinase in a material ratio of 1:5:8 : 4 components, taken out and drained, then added to the composite trace element aqueous solution to soak for 8 hours, freeze-dried, pulverized, then added 8kg calcium dihydrogen phosphate and 6kg calcium lactate and mixed evenly to obtain the first material;

[0049] In the above composite trace ...

Embodiment 3

[0052] A method for preparing a compound feed additive for reducing limb and hoof diseases in sows, comprising the steps of:

[0053] S1. Sinter the dried rice husks in an oxygen-free environment for 45 minutes, the sintering temperature is 275° C. to form partially carbonized rice husks; then add 100 kg of partially carbonized rice husks to the compound enzyme preparation for enzymatic hydrolysis for 16 hours, and the enzymatic hydrolysis temperature is 37° C. The water content of the compound enzyme preparation is 55wt%, the specific activity of the compound enzyme preparation is 9000-11000U / g, and the compound enzyme preparation is composed of protease, amylase, cellulase and pectinase according to the material ratio of 1.8:4.3:9.5 : 2.5 composition, taken out and drained, then added to the composite trace element aqueous solution to soak for 11 hours, freeze-dried, pulverized, then added 5kg calcium dihydrogen phosphate and 12kg calcium lactate and mixed evenly to obtain th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific vitality | aaaaa | aaaaa |

| Effective viable count | aaaaa | aaaaa |

| Specific vitality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com