Carbon fiber cloth and pasting method of carbon fiber composite material composed of carbon fiber cloth

A carbon fiber cloth and composite material technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of joint failure and fracture, uneven stress dispersion, product performance decline, etc., to achieve balanced force, uniform stress distribution, and improved The effect of product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation of the present invention will be described in detail below in conjunction with examples. It should be understood that the examples are provided to illustrate the invention and not to limit the invention. The scope and essential content of the present invention are defined by the claims.

[0020] 1. Design the mold according to the product size.

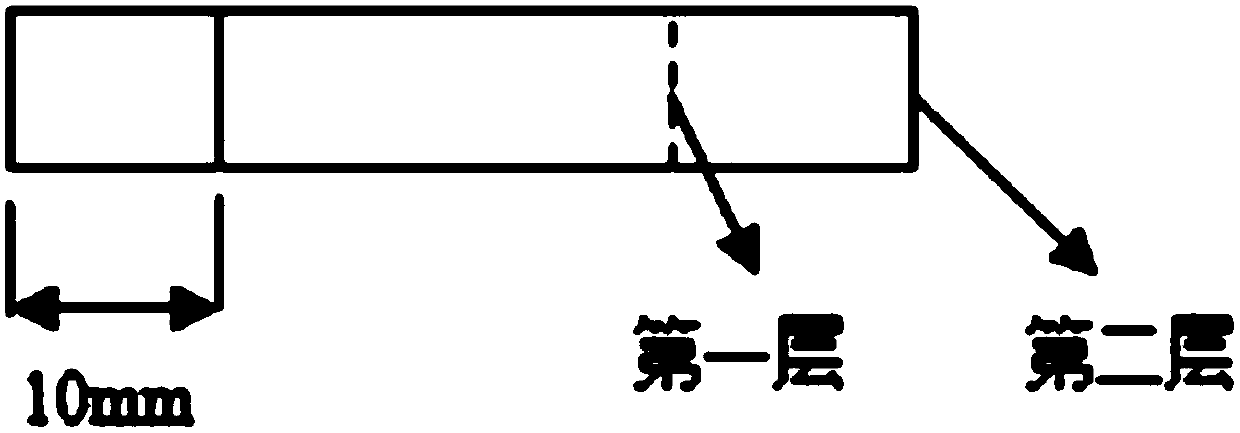

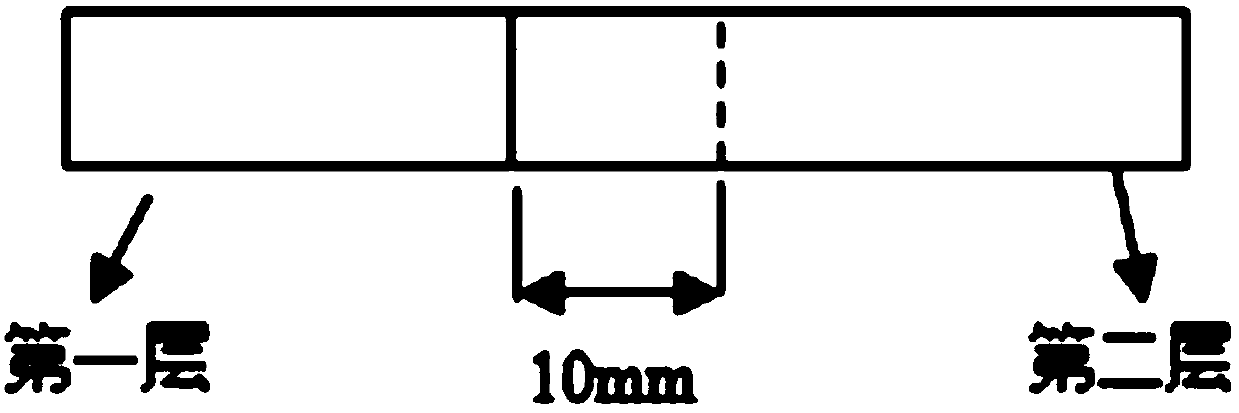

[0021] 2. Design the size of the carbon fiber cloth according to the size of the mold, and determine the cutting point (that is, the position of cutting and folding, which will help the product size to be more accurate).

[0022] The carbon fiber cloth used is impregnated with resin and carbon fiber and then cured. The carbon fiber cloth is formed by interlacing a bunch of carbon fiber bundles according to 0°, ±20°, ±45° to form staggered angles. 0° yarn can reinforce the rigidity of carbon fiber filaments; 20° can increase the tensile strength of carbon fiber filaments; 45° can reinforce the shea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com