Electronic equipment shell, preparation method thereof and electronic equipment

A technology for electronic equipment and shells, which is applied in the field of electronic equipment shells and their preparation, and can solve the problems of limited appearance effects of electronic equipment shells, inability to effectively adjust brightness and optical effects, and needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

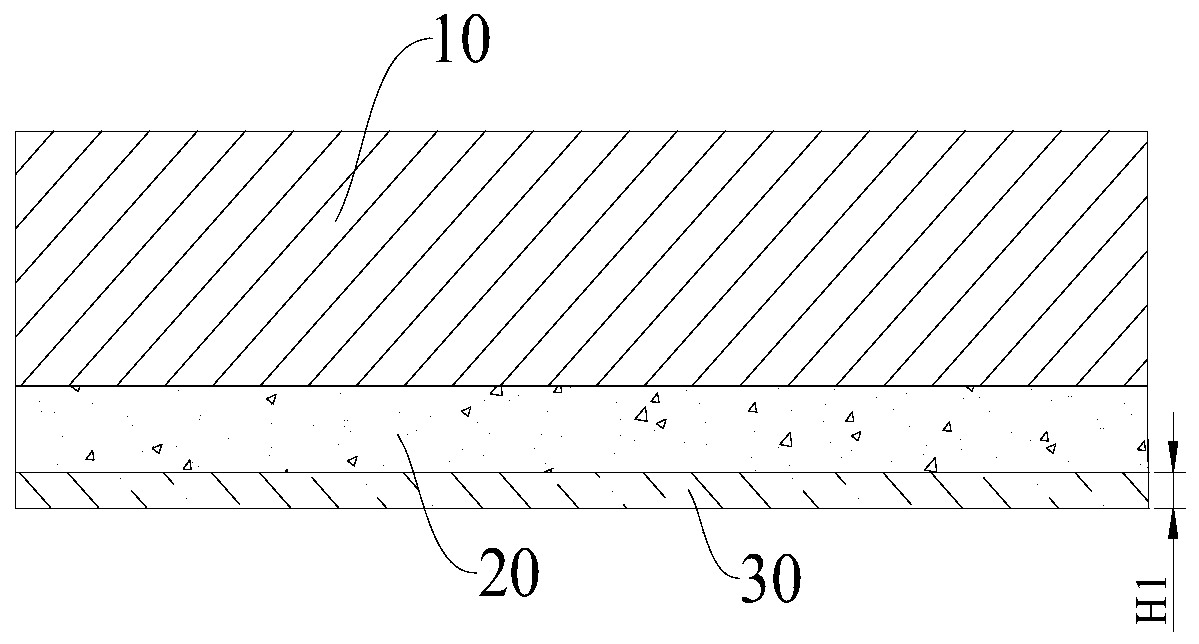

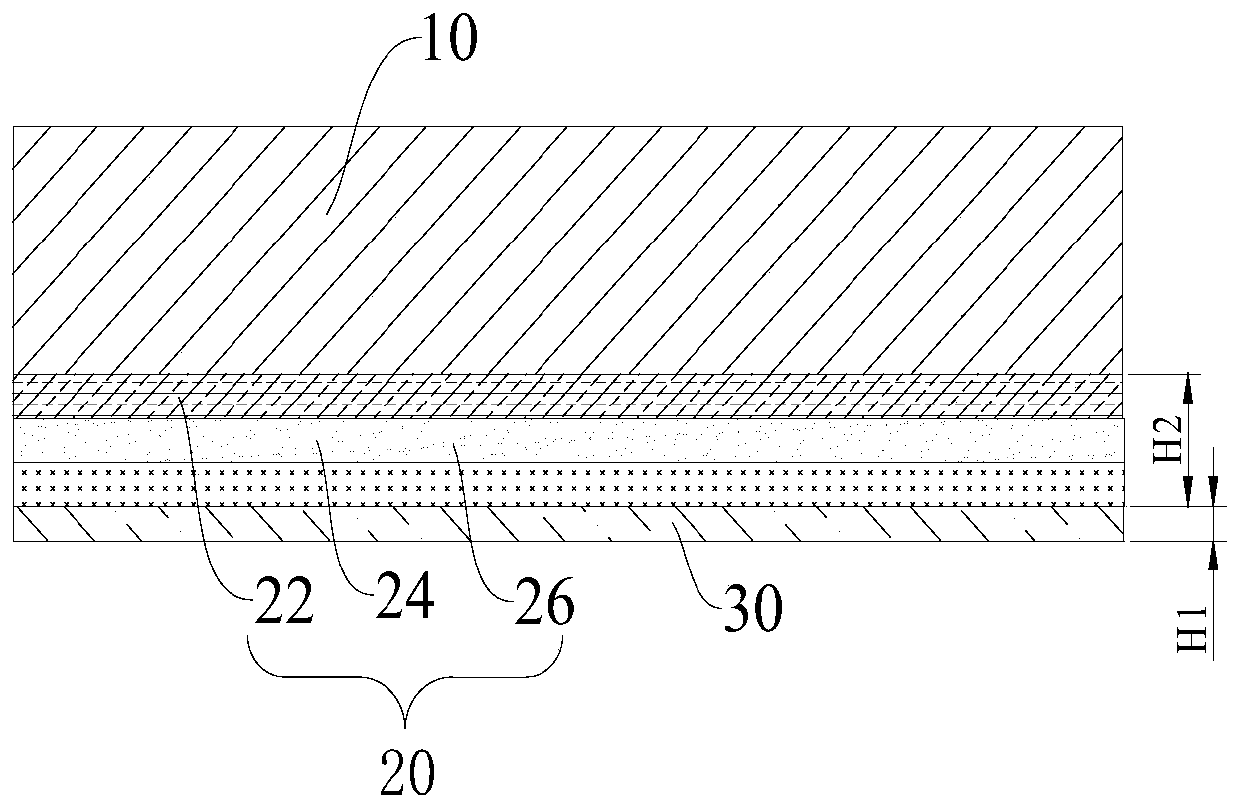

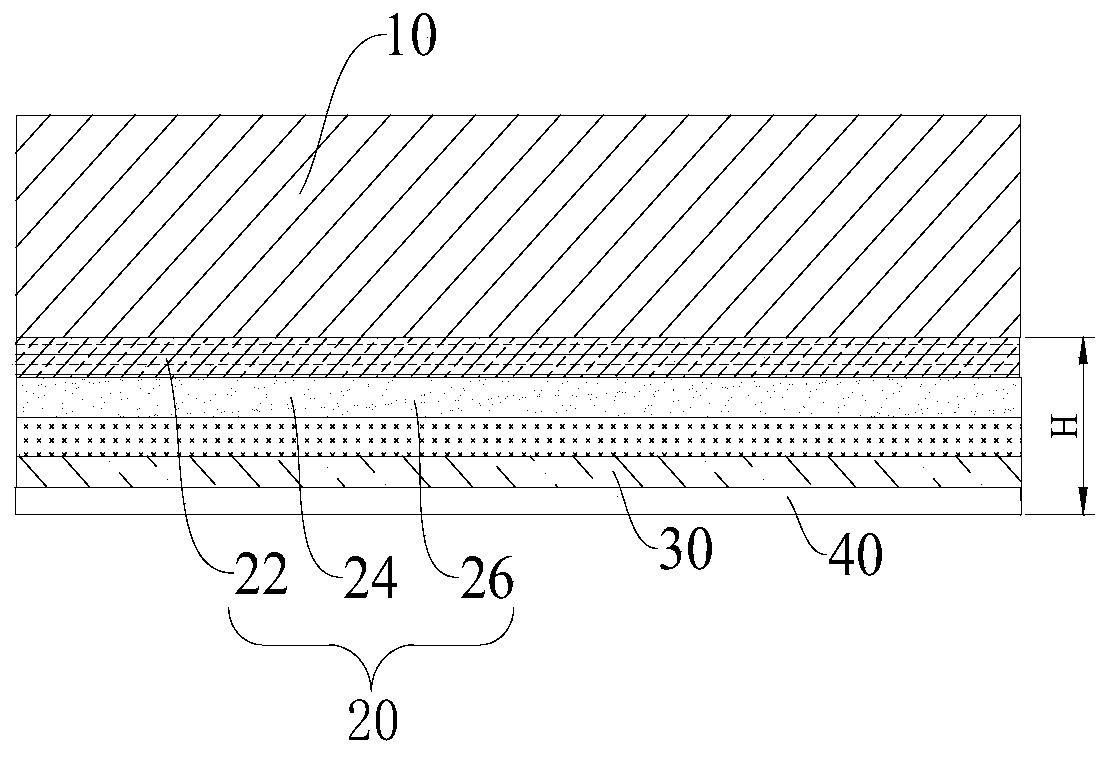

Examples

Embodiment 1

[0060] Preparation:

[0061] 1. Composite sheet preparation: Cut the PC+PMMA composite sheet to the required size.

[0062] 2. UV transfer printing: After tearing off the protective film on the PC surface of the composite board and performing electrostatic dust removal treatment, the UV transfer printing equipment is used to transfer a transparent UV coating on the PC surface, and the transfer is cured at the same time to form a UV texture layer.

[0063] 3. Vacuum coating: by evaporation plating, three layers of high-low-high refractive index oxide film layers of titanium dioxide layer, silicon dioxide layer and titanium dioxide layer are formed on the UV texture layer, and InSn metal is formed on the oxide film layer functional layer, and then form Si or Nb on the metal functional layer 2 o 5 or Si+Nb 2 o 5 Composite protective layer. In this step, the thickness of each film layer is adjusted to be different, and multiple shells are prepared respectively. For the specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com