Light low-resistance high-strength carbon fiber hub

A high-strength carbon fiber, carbon fiber technology, applied in the direction of hubs, wheels, spoke wheels, etc., can solve the problem that the hub is difficult to meet the low resistance, light weight, high strength, etc., to facilitate maintenance and replacement work, eliminate friction, reduce friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

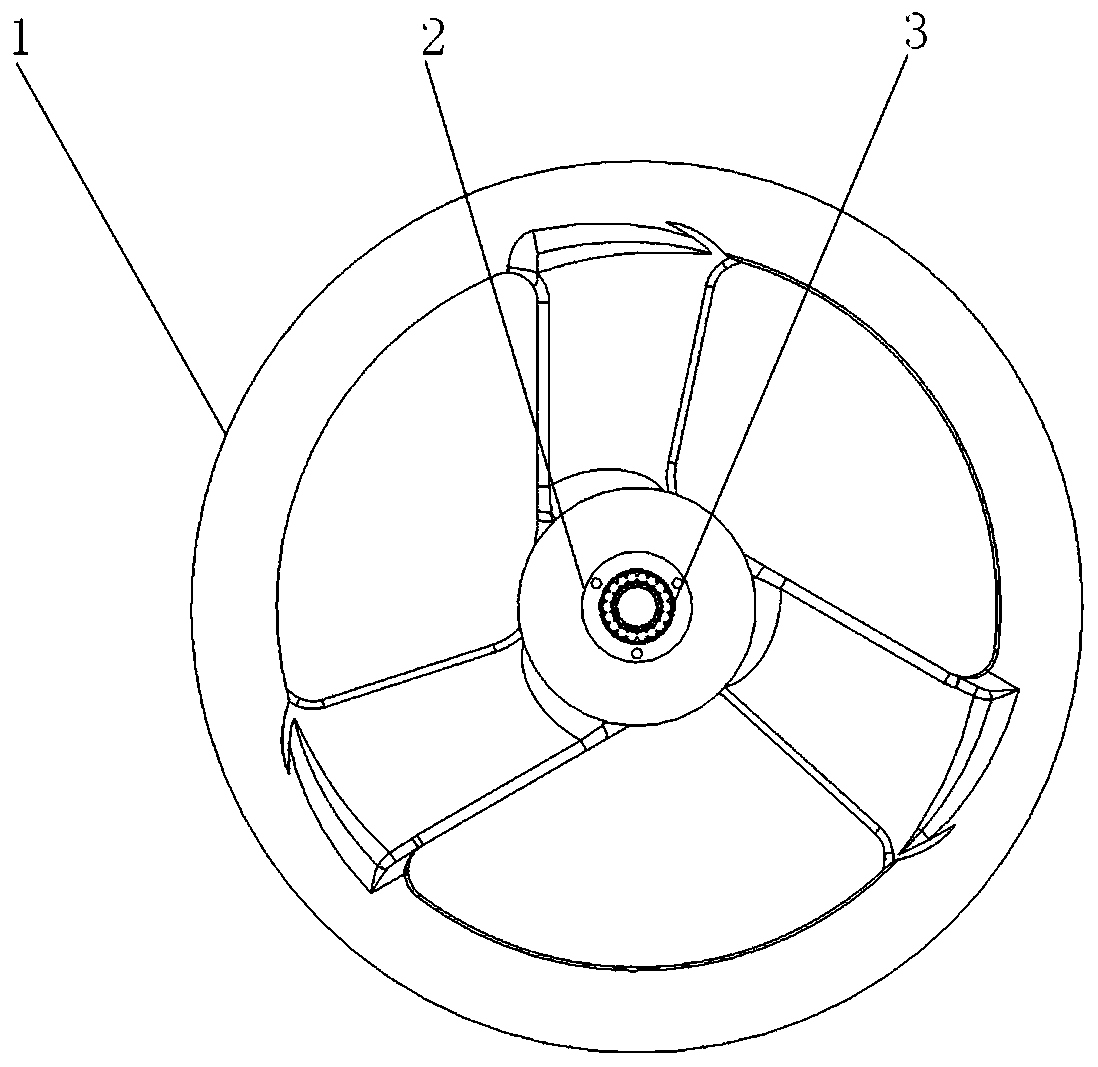

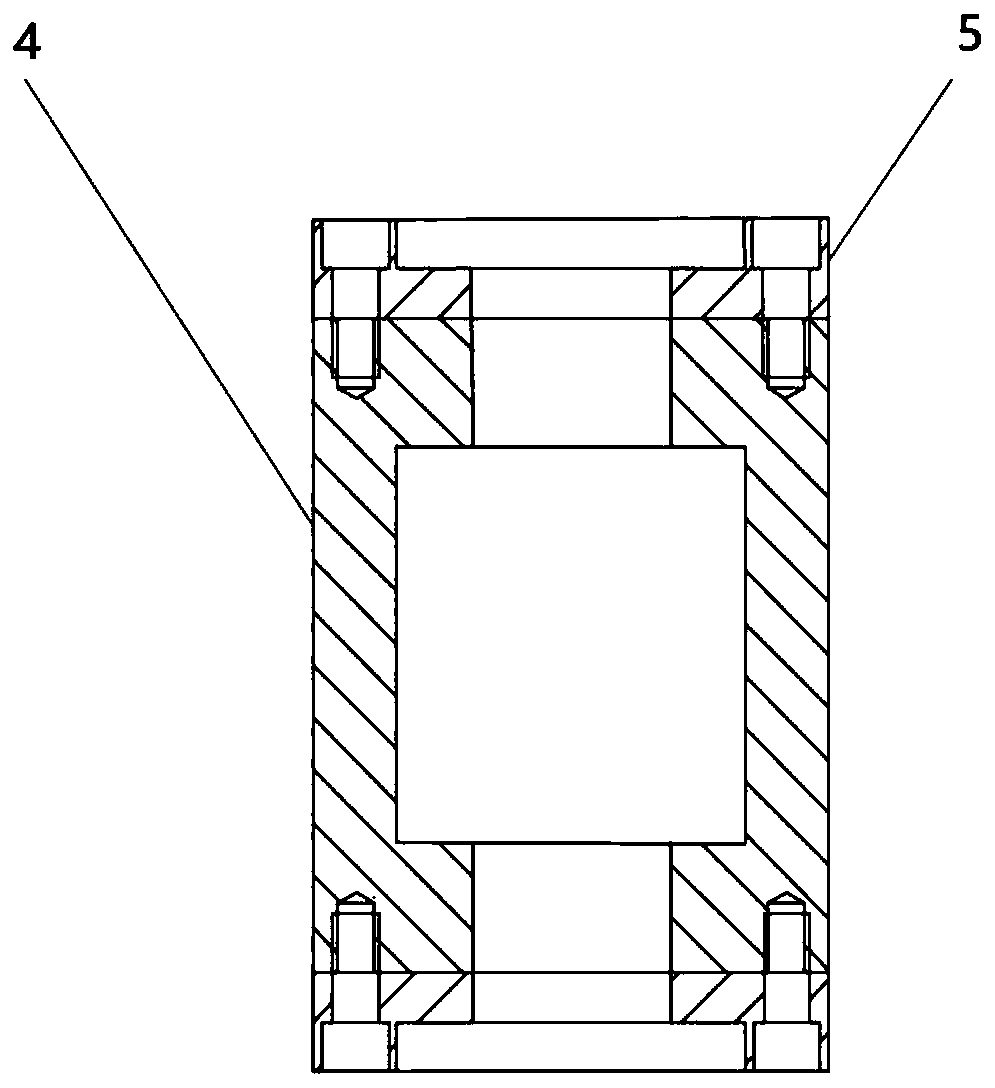

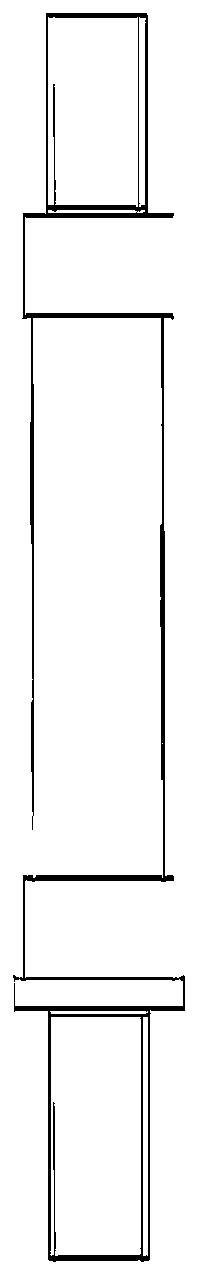

[0019] to combine Figure 1-4 , the present invention is a light-weight, low-resistance, high-strength carbon fiber hub. The carbon fiber wheel body 1 and the center part 2 of the hub are die-cast in a mold to combine them into a whole; the bearing plates 5 on both sides and the high-strength aluminum alloy hub 4 Connected by bolts, the silicon nitride bearing 3 is in interference fit with the bearing plate 5 , and the high-strength aluminum alloy shaft is in interference fit with the silicon nitride bearing 3 . The carbon fiber wheel body 1 is made of carbon fiber. The high-strength aluminum alloy hub 4 is made of 7075 aluminum alloy. The making material of bearing retainer 5 is 7075 aluminum alloy, and its concave bearing hole aperture diameter is less than bearing internal diameter. The high-strength aluminum alloy shaft is made of 7075 aluminum alloy, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com