Rewinding machine

A technology of rewinding machine and rewinding roller, which is applied in the field of rewinding machine, can solve problems such as low efficiency of winding paper, uncontrollable quality of finished products, and inability of rewinding roller to work independently, so as to improve winding stability and improve The effect of stable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

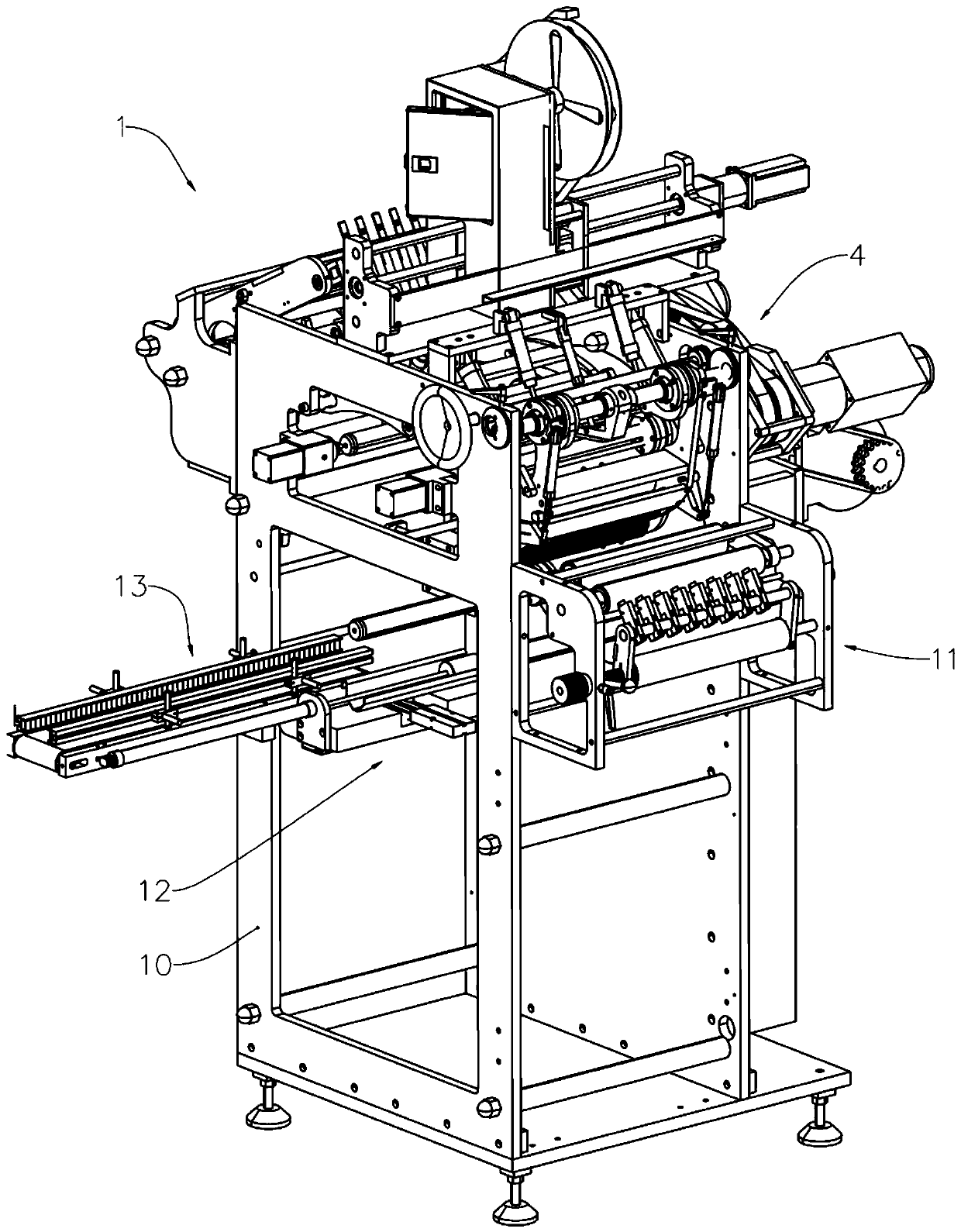

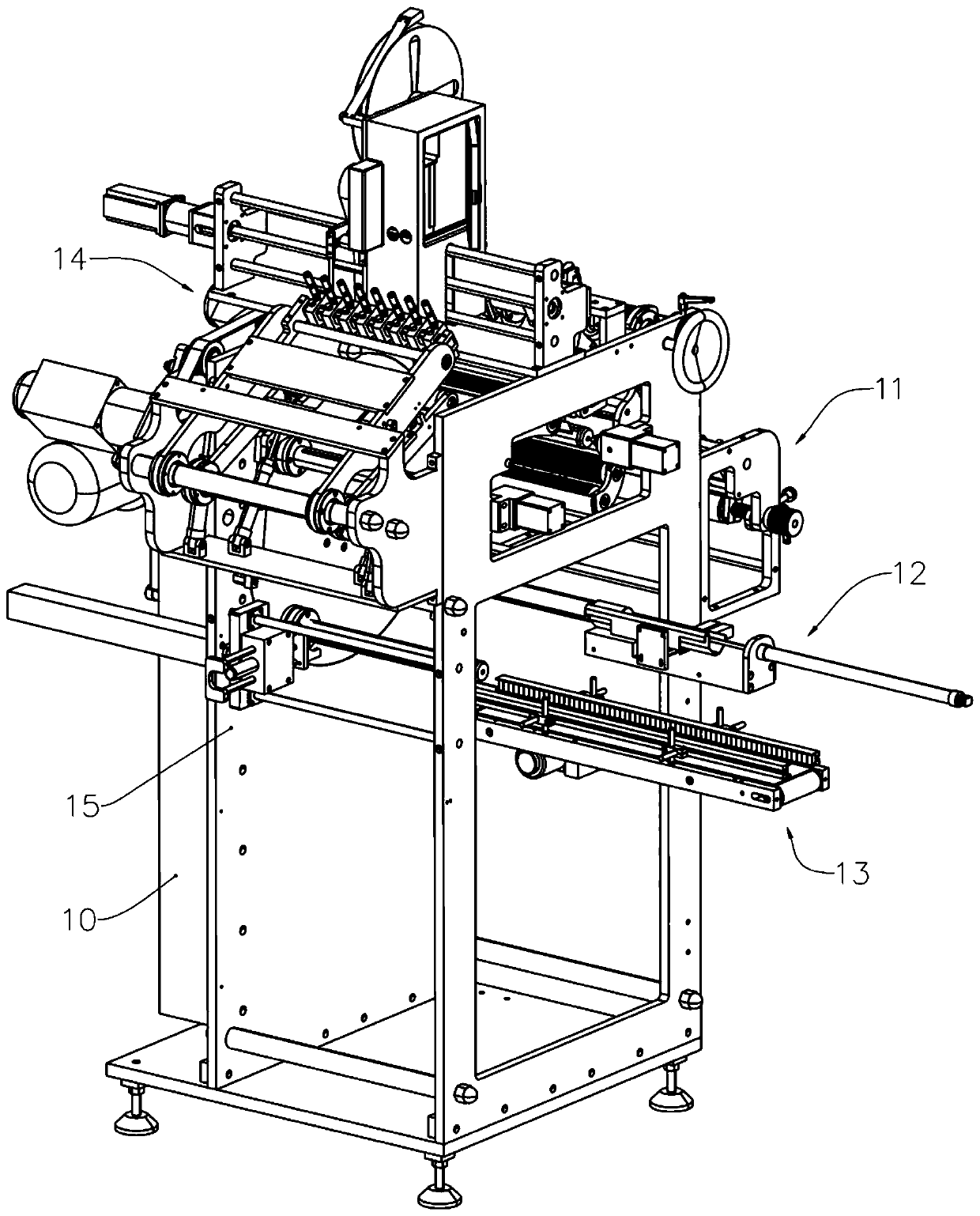

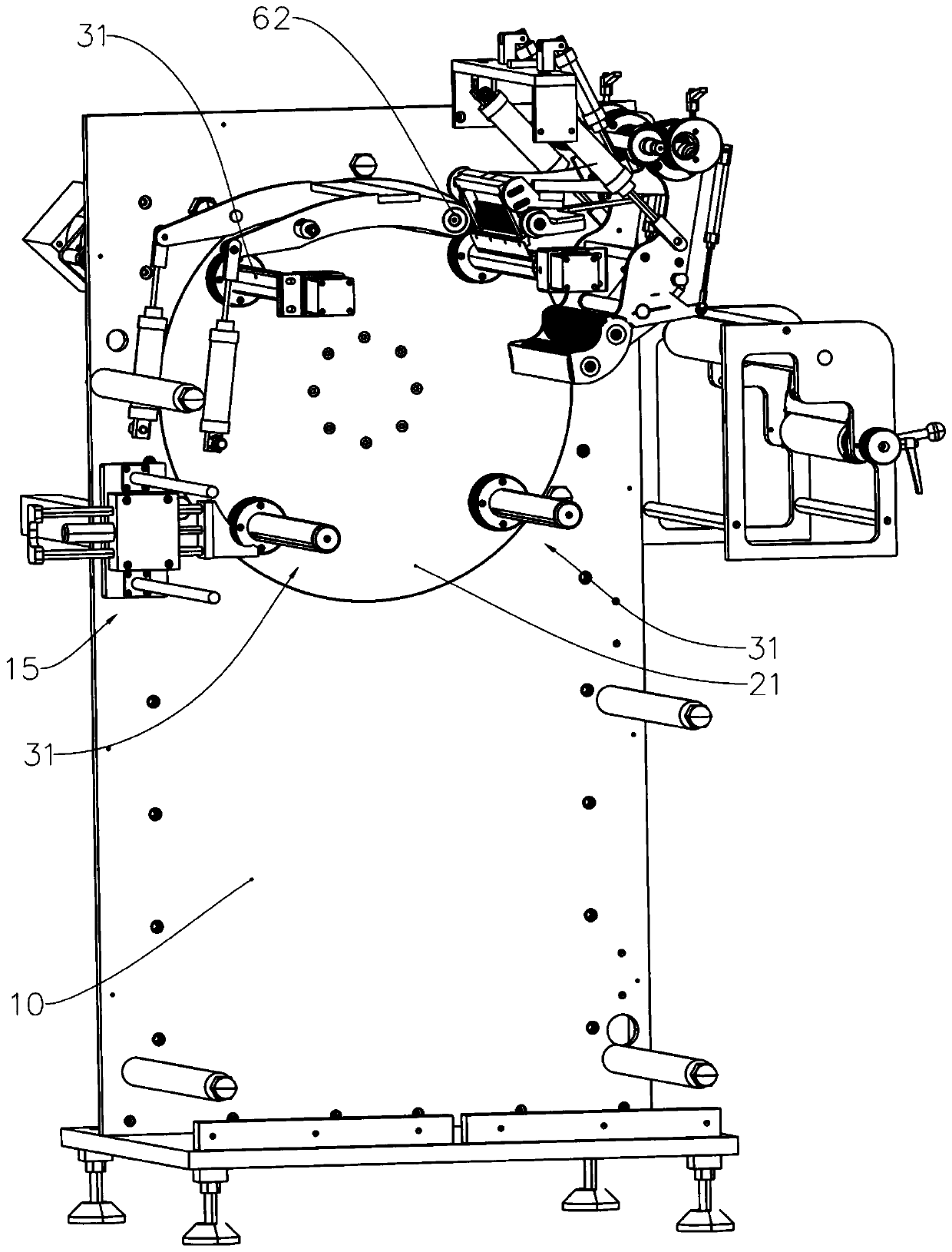

[0029] refer to Figure 1 to Figure 3 , the rewinding machine includes a winding device, a paper feeding device 11, an upper pipe device 12, a conveying device 13, a labeling device 14 and a blanking device 15, and the upper pipe device 12 is used to feed the rewinding roller 31 to the paper roller, and a plurality of The paper roll is sleeved on the rewinding roller 31 in the axial direction, and a blade is provided on the paper feeding device 11. The label paper is input from the paper feeding device 11 and output toward the rewinding roller 31. When inputting, it is divided by the blade, and then a single The label paper is wound by a paper roll. After the preset number of turns is wound, the rotating disc in the middle rotates, and then rotates to the labeling device 14, which is affixed with a plurality of marks, and the label paper of the rewinding roller 31 is packaged and fixed through the marks. Then, through the rotation of the turntable, turn to the unloading devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com