Double-side efficient winding machine

A winding machine, high-efficiency technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problem of low utilization rate of movable racks, and achieve smooth rotation, utilization, and synchronization. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

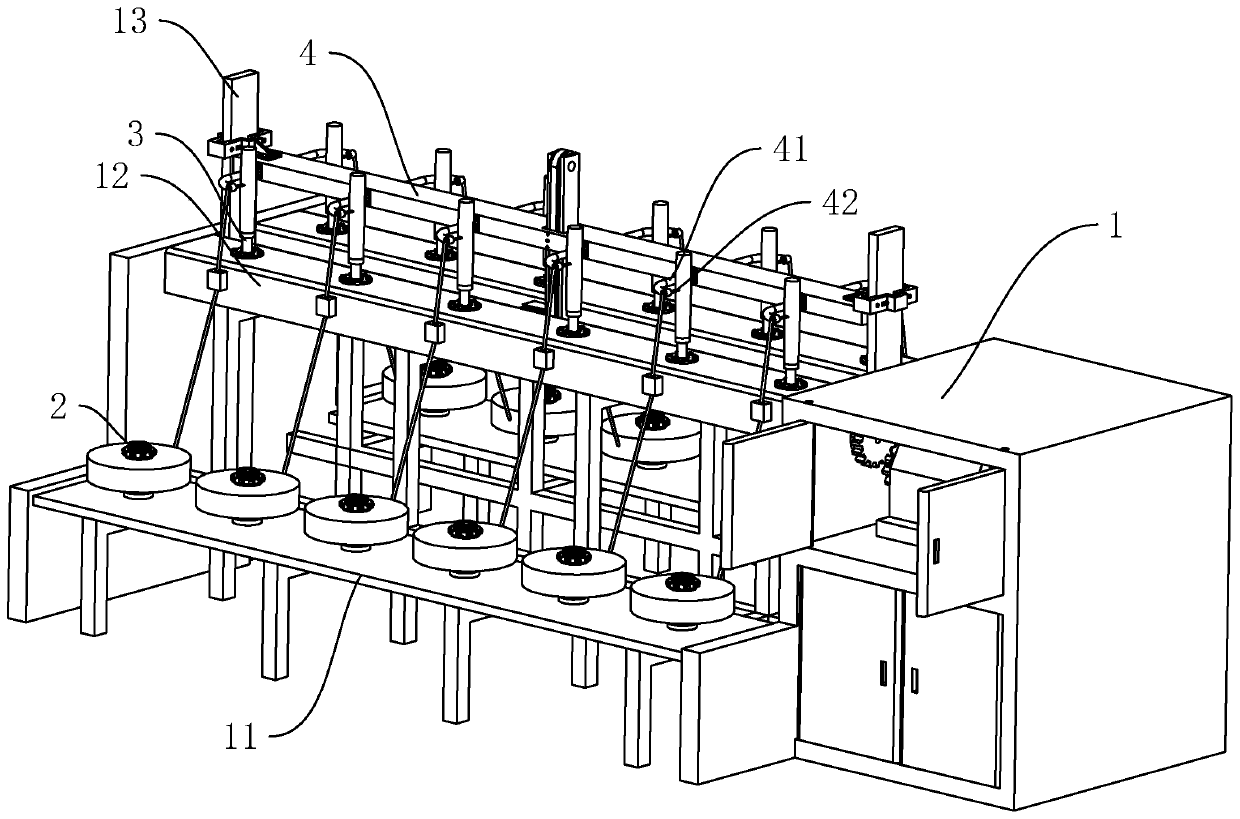

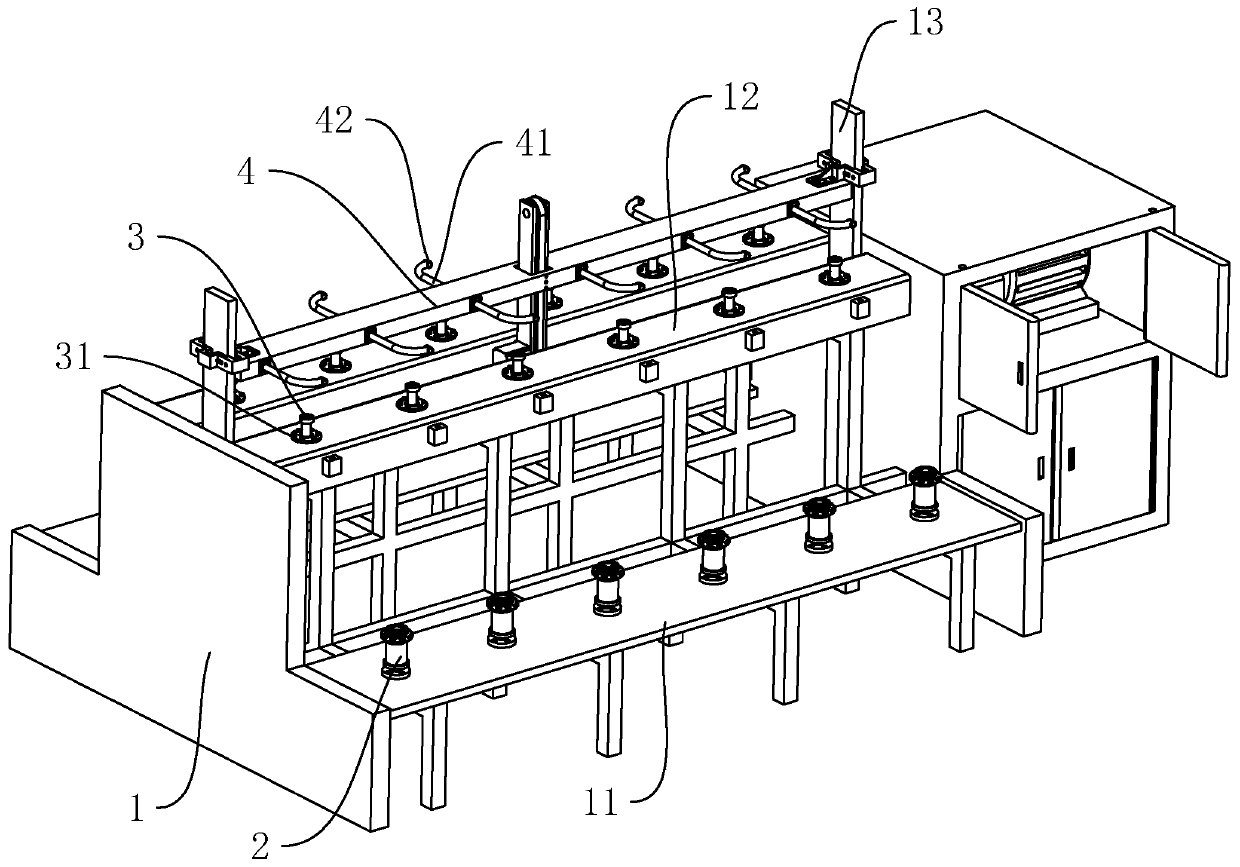

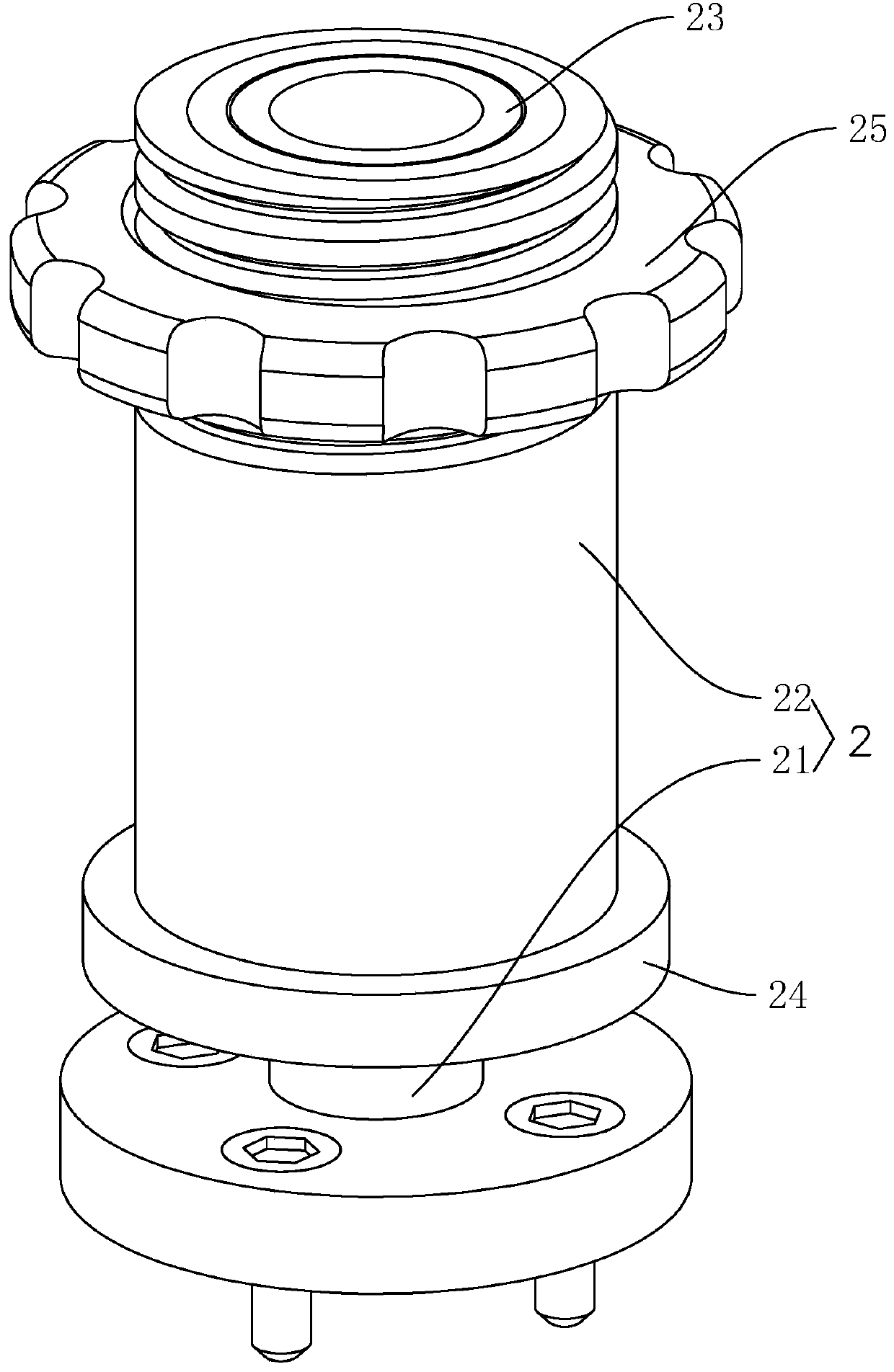

[0032] Double-sided high-efficiency winder, such as figure 1 , figure 2As shown, it includes a frame 1, a raw yarn shaft 2, a bobbin socket 3 and a movable frame 4. The frame 1 is welded and fixed with two raw yarn bearing plates 11, and a plurality of raw yarn shafts 2 rotate vertically at equal intervals. On two raw yarn bearing plates 11; the frame 1 is welded and fixed with two winding bearing beams 12 above the raw yarn bearing plate 11, and a plurality of winding tube sockets 3 rotate vertically on the two winding yarn bearings at equal intervals respectively. beam 12, and a plurality of winding bobbin sockets 3 correspond to a plurality of original yarn shafts 2 one by one, and the frame 1 is provided with a driving device for driving the winding bobbin sockets 3; There are two vertical guide rails 13 arranged between them, and the two ends of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com