A material with temperature-sensitive change and optical angle-dependent color difference and its preparation method

A color-dependent and temperature-changing technology, which is applied in the field of materials with temperature-sensitive changes and optical angle-dependent color changes and its preparation, can solve the problems that temperature-changing materials have no color change with angle, no temperature-sensitive color change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

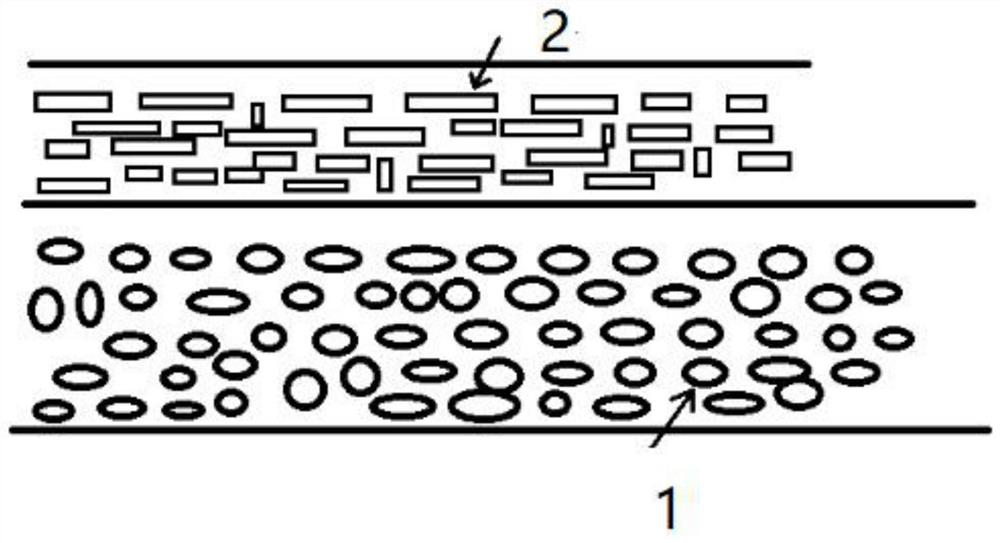

[0035] structured as figure 1 A material with temperature-sensitivity change and optical angle-dependent color difference is shown, including temperature-changing material and optical angle-dependent color-dependent material, forming a layered structure, and the basic structure is a temperature-changing material layer and an optical angle-dependent color-dependent material layer Alternately. The preparation method is as follows:

[0036] 1) Deposit, coat, ink, spray, coat, and fill a layer of temperature-changing material on one side of the material;

[0037] 2) Then deposit, coat, ink, spray, coat, and fill a layer of color-dependent material on the same side or the other side to obtain a material with temperature-sensitive change and optical color-dependent color.

Embodiment 2

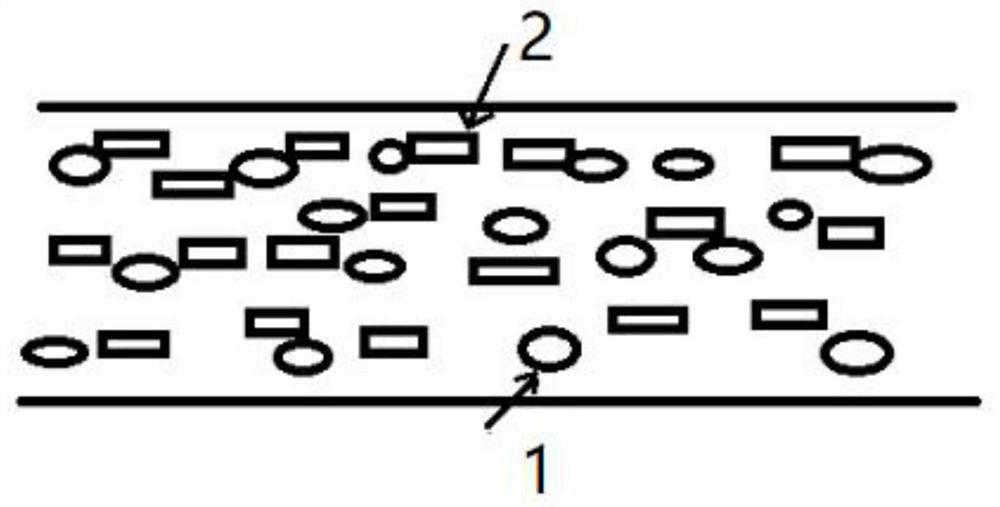

[0039] structured as figure 2 The shown material with temperature-sensing change and optical angle-dependent color change includes temperature-changing material and optical angle-dependent color-dependent material to form a mixed structure. The preparation method is as follows: the temperature-changing material and optical angle-dependent color-dependent material are combined The color materials are mixed evenly, and a mixed structure is formed through adsorption, coating, ink making, spraying, coating, filling, etc., to obtain materials with temperature-sensitive changes and optical angle-dependent changes.

Embodiment 3

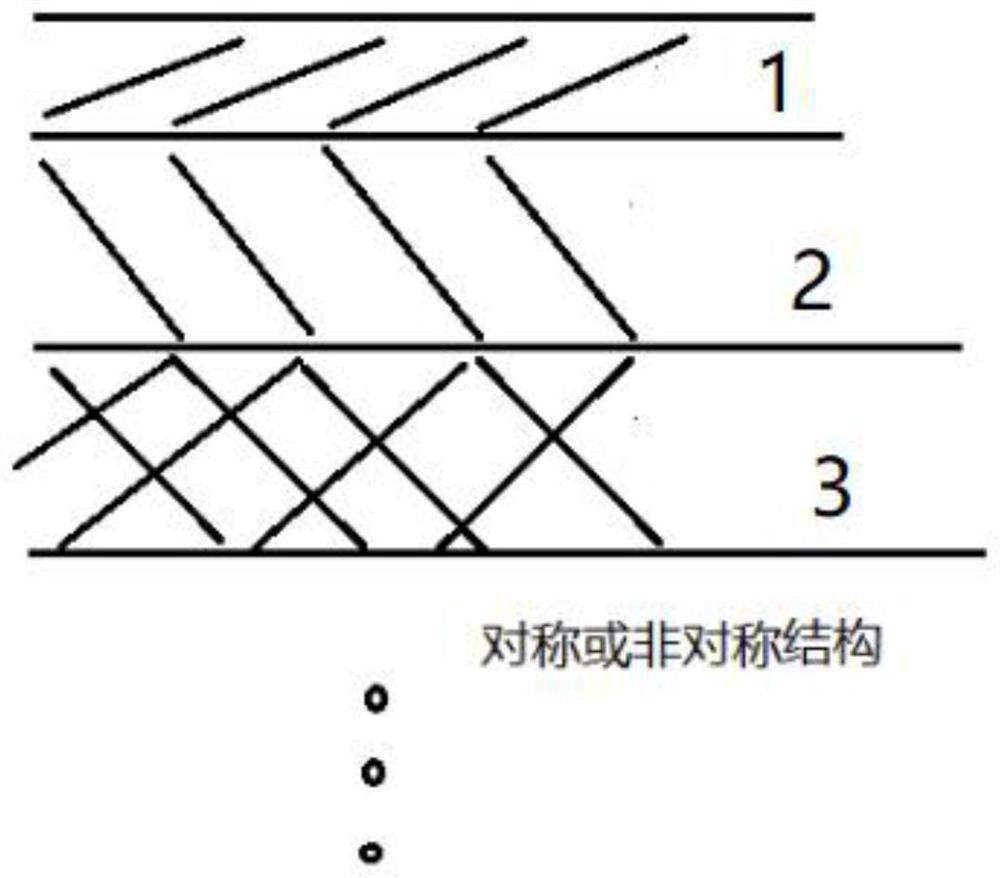

[0041] structured as image 3 A material with temperature-sensing change and optical angle-dependent color difference is shown. The temperature-changing material is used as the film structure of the optical functional layer in the film structure, and has a typical optically variable material structure-core structure: respectively, temperature In addition to the core structure, the variable material layer / medium layer / temperature-changing material layer or reflective layer / medium layer / temperature-changing material layer can also be modified with several other layers as a protective or optical function layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com