On-line measurement method of indentation depth on solder joint surface based on displacement signal between electrodes

A technology of displacement measurement and displacement signal, which is applied in the direction of measuring devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as low efficiency, difficulty in meeting the needs of automatic production, and large impact on results, and achieve accurate measurement, fast calculation speed, hardware The effect of low system requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

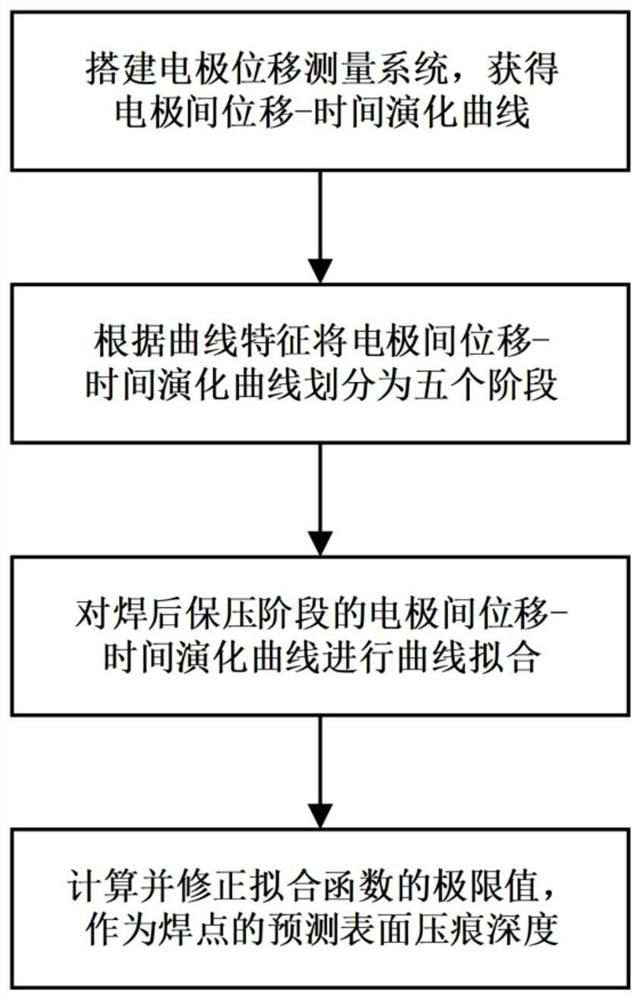

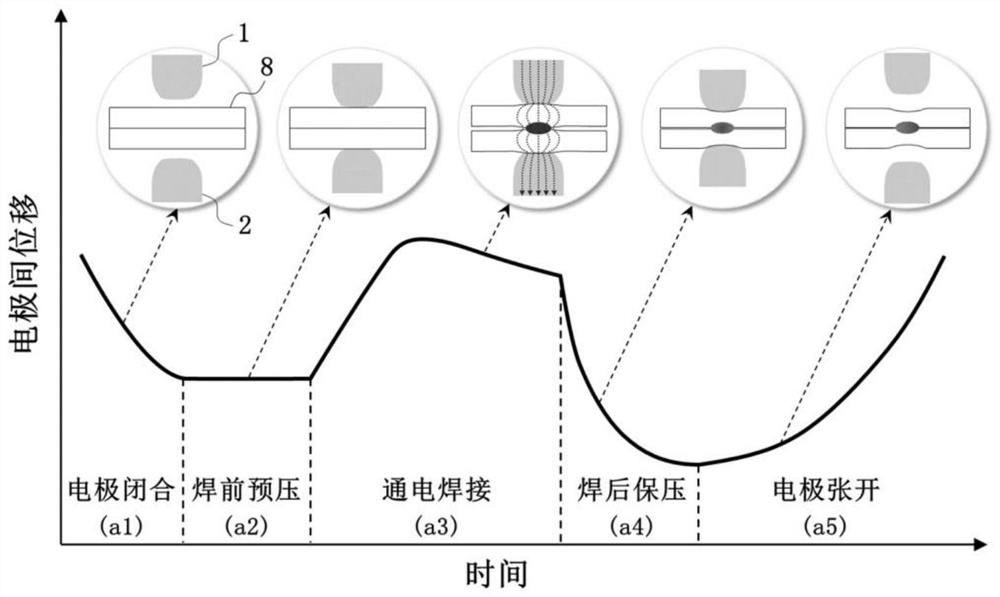

[0020] Such as figure 1 As shown, the present embodiment specifically measures the surface indentation depth of the spot welding joint through the following steps:

[0021] 1) Build a displacement measurement device to obtain the displacement-time evolution curve between electrodes.

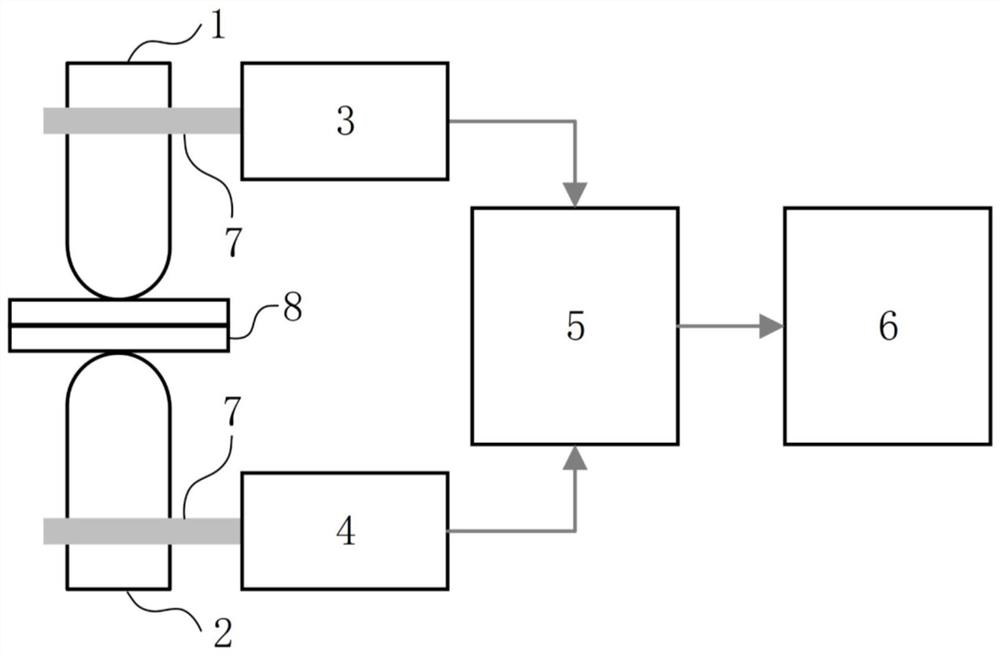

[0022] Such as figure 2 As shown, the displacement measurement device includes: a first electrode 1, a second electrode 2, a first displacement sensor 3, a second displacement sensor 4, a signal acquisition module 5 and a calculation and analysis module 6, wherein: the electrodes 1 and 2 and the displacement sensor 3 and 4 are connected correspondingly through the installation aid 7, the input end of the signal acquisition module 5 is connected with the two displacement sensors 3 and 4 respectively, and the output end of the signal acquisition module 5 is connected with the calculation and analysis module 6, so as to realize the connection between the two electrodes 1 and 2 The displacement va...

Embodiment 2

[0036] Compared with Embodiment 1, the first electrode displacement sensor 3 adopts a reflective baffle, the second electrode displacement sensor 4 adopts a laser displacement sensor, the reflector is installed opposite to the laser displacement sensor, and the laser displacement sensor outputs an electrical signal, and The sensitivity is 1V / mm and the resolution is 1μm. The signal acquisition module 5 directly collects the electrical signal output by the second electrode displacement sensor 4 , and converts the unit to obtain an inter-electrode displacement-time evolution curve, and transmits it to the calculation and analysis module 6 .

[0037] The fitting function of this embodiment is: f(x)=A(1 / arctan(x+B)-2 / π)+C1, wherein: A, B, and C1 are undetermined coefficients and A is greater than 0. Since A(1 / arctan(x+B)-2 / π) is 0 when the independent variable x tends to infinity, C1 is the function value when the independent variable tends to infinity. The predicted value of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com