Flat knitting machine needle selector detection system

A detection system and needle selector technology, applied in knitting, weft knitting, electrical testing/monitoring, etc., can solve the problem of building a large system, increasing the difficulty and workload of testers, and failing to detect needle selectors Quantification and other issues, to achieve the effect of strong expansion performance, solve the problem of delay and response index quantification, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

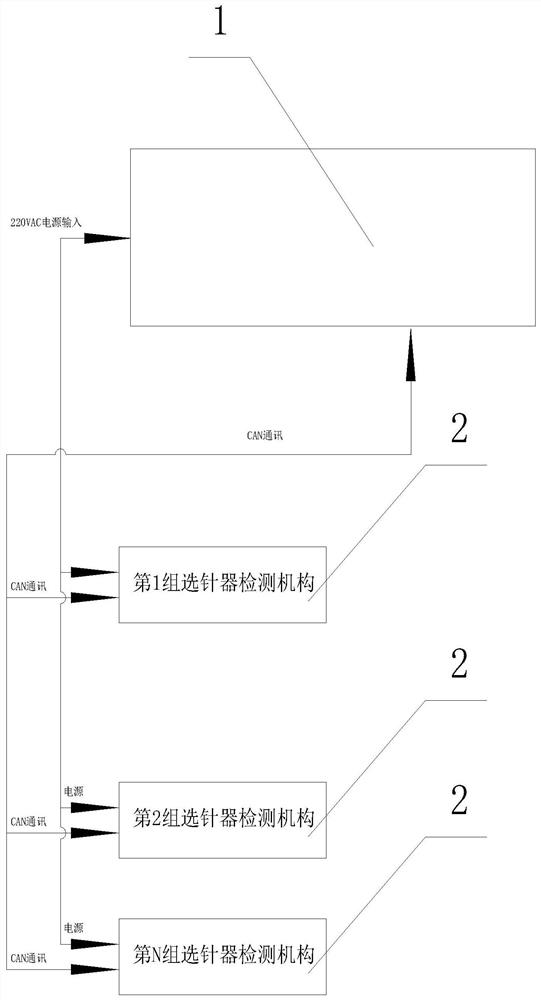

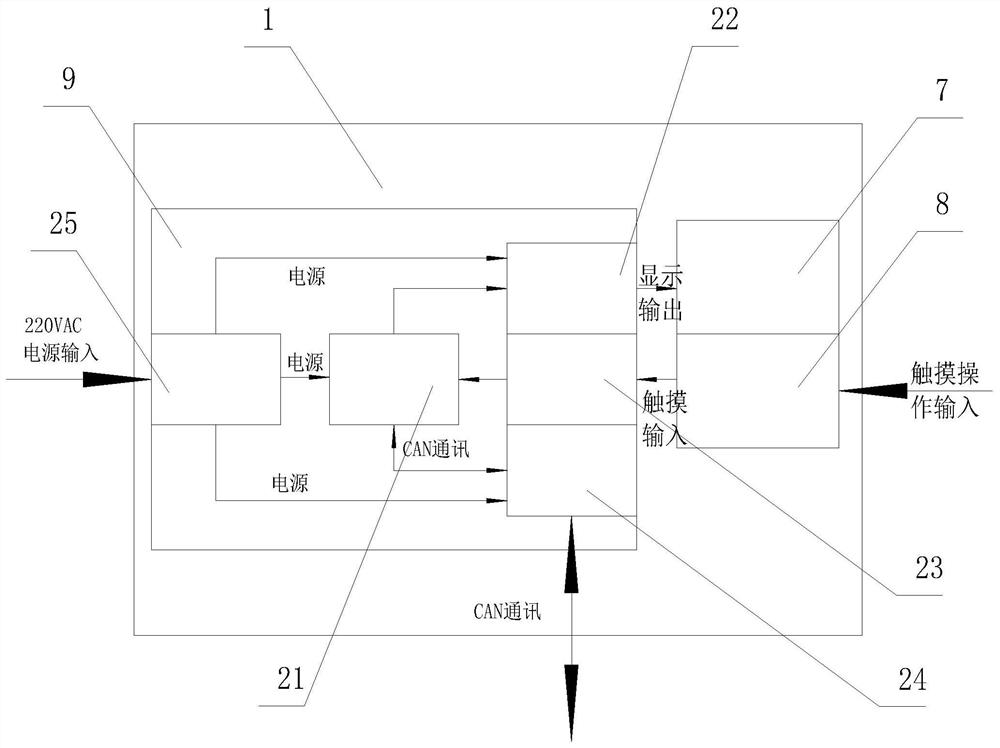

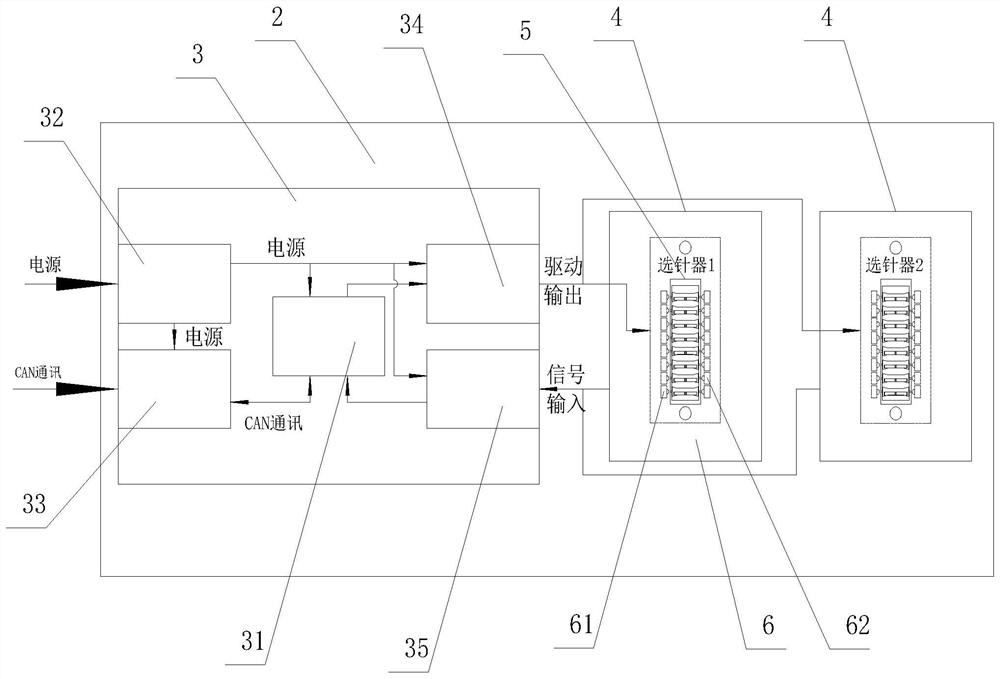

[0026] refer to Figure 1 to Figure 3 , the present invention includes a man-machine operation control box 1 and at least one set of needle selector detection mechanisms 2, the first set of needle selector detection mechanisms, the second set of needle selector detection mechanisms and the Nth set of needle selectors are used in this embodiment detection mechanism to indicate the number of needle selector detection mechanisms 2 included, the man-machine operation control box 1 is electrically connected to the needle selector detection mechanism 2, and each group of needle selector detection mechanisms 2 is assembled to two 8-knife Measuring the needle selector, the needle selector detection mechanism 2 is provided with a control detection board 3 and an action position detection mechanism 4, the man-machine operation control box 1 is connected with the control detection board 3 CAN bus, and the action position detection mechanism 4 is connected to the needle selector The param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com