An integrated optimization method for production planning and scheduling under uncertain requirements

A technology of production planning and production scheduling, which is applied in calculation, data processing application, forecasting, etc., and can solve problems such as only considering production planning and production scheduling, difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

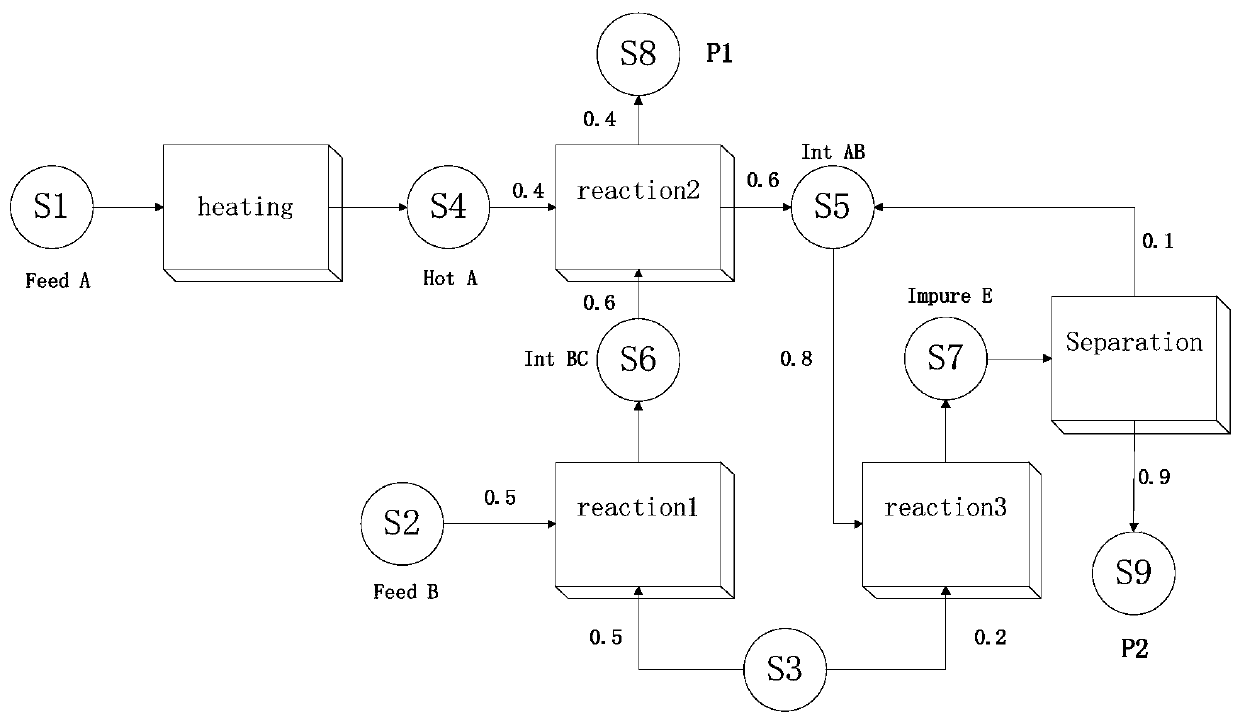

[0074] A multi-product batch chemical production plant can produce two products (P 1 ,P 2 ). The state task network diagram of its technological process is as follows figure 1 . The reaction process of Reaction 1, Reaction 2 and Reaction 3 can all be carried out in Reactor 1 and Reactor 2. The production planning cycle considered in the example is 40 hours, and the production planning cycle is divided into 5 production scheduling cycles.

[0075] The data of production scheduling process is shown in Table 1 and 2, the data of cost part is shown in Table 3, and the data of production planning cost part is shown in Table 4.

[0076] Table 1 Production Equipment Process Data

[0077]

[0078] Table 2 Material status data (--- means unlimited)

[0079]

[0080] Table 3 Production Scheduling Cost Data

[0081]

[0082] Table 4 Production planning cost data

[0083]

[0084] Uncertain market demand is shown in Table 5.

[0085] Table 5 Market demand for differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com