Camera calibration and flat field correction device, camera calibration method and flat field correction method

A camera calibration and correction device technology, which is applied in image data processing, instruments, calculations, etc., can solve the problems of high price, large volume, and large radiation energy of the integrating sphere, and achieve the effect of fast and accurate camera calibration and flat field correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

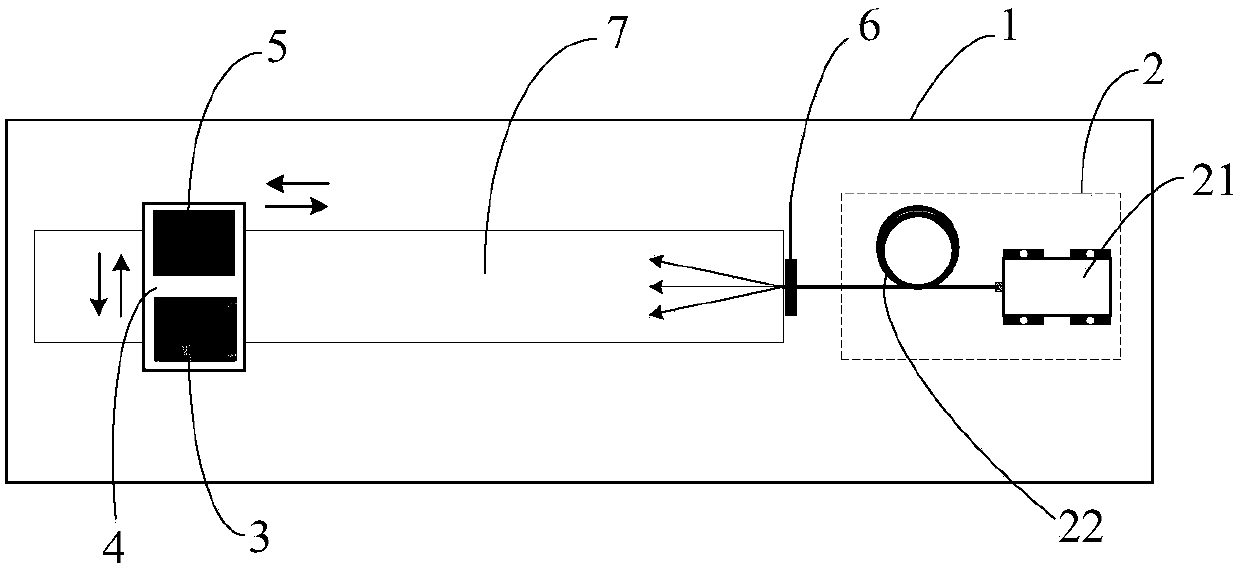

[0037] This embodiment provides a camera calibration and flat field correction device. This device is mainly used for camera calibration and flat field correction to correct the imaging gray value of each pixel of the camera to be equal or nearly equal to meet the needs of use, such as calibration and flat field correction. Calibrate the fluorescence imaging camera on the gene sequencer.

[0038] Such as figure 1 As shown, the camera calibration and flat field correction device of this embodiment mainly includes a camera obscura 1 , a light source generator 2 , a reference camera 3 and a mobile platform 4 .

[0039] The dark box 1 is a light-tight sealed box. The dark box 1 is rectangular and placed horizontally. All other components of the device are installed in the dark box 1 to avoid interference from external light to the detection.

[0040] The light source generator 2 is installed at one end in the dark box 1. The light source generator 2 includes an LED light source 2...

Embodiment 2

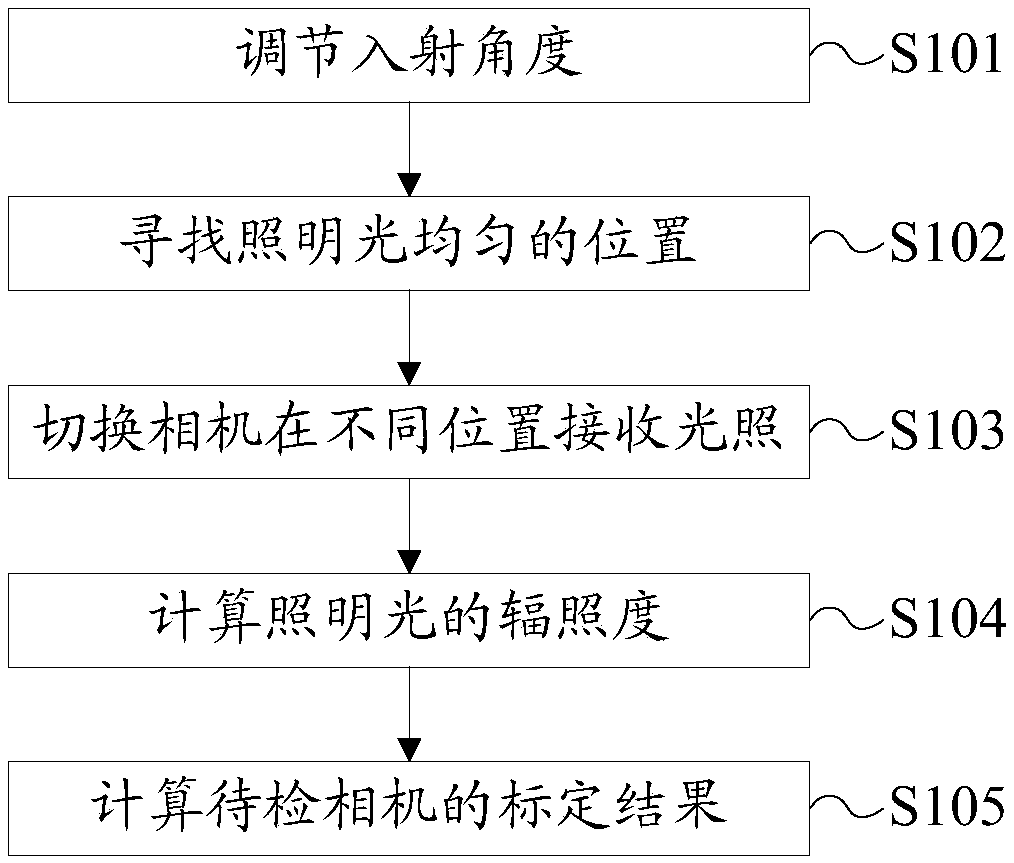

[0054] This embodiment provides a camera calibration method, which is implemented based on the camera calibration and flat field correction device in the first embodiment above.

[0055] Such as figure 2 As shown, the camera calibration method in this embodiment includes the following steps:

[0056] S101: adjusting the incident angle;

[0057] Adjust the optical axis of the illumination light through the installation end on the upper end of the optical fiber mounting bracket 6 to keep it horizontal, and adjust the reference camera 3 to align with the emission end of the optical fiber 22 through the vertical movement of the mobile platform 4, so that the illumination light emitted by the LED light source 21 is vertically incident on the Base camera 3;

[0058] S102: Find a position where the illumination light is uniform;

[0059] Turn on the LED light source, observe the uniformity of the image in real time from the image of the reference camera 3, and adjust the distance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com