Enhanced cooling device having PCM packaged particles and method

A heat dissipation device and particle technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of high fan air volume and air pressure requirements, loud fan noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

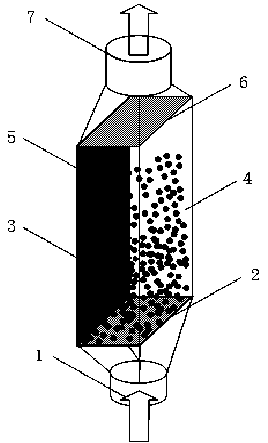

[0012] When the space is narrow and the electronic heat dissipation is applied, the working process of the heat dissipation device mentioned in the present invention is as follows: the air enters the device from the air inlet, and after passing through the distributor, the encapsulated PCM particles in the inner cavity of the device are agitated to make it flow in the device. A fountain-like flow is formed in the inner cavity. During the flow process, the PCM particles contact and collide with the hot wall of the device. During the collision process, not only the air boundary layer near the hot wall of the device is destroyed, the heat exchange between the air and the hot wall of the device is strengthened, but also the PCM particles and the device The heat conduction phenomenon of the hot wall surface during the collision process will also strengthen the heat dissipation of the hot wall surface of the device, and the mutual collision heat exchange between the PCM particles wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com