Novel automobile chassis rapid-switching robot welding station

A technology for robot welding and automobile chassis, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. It can solve the problems of low efficiency and long replacement time of products to be welded, and achieve fast replacement, space saving and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

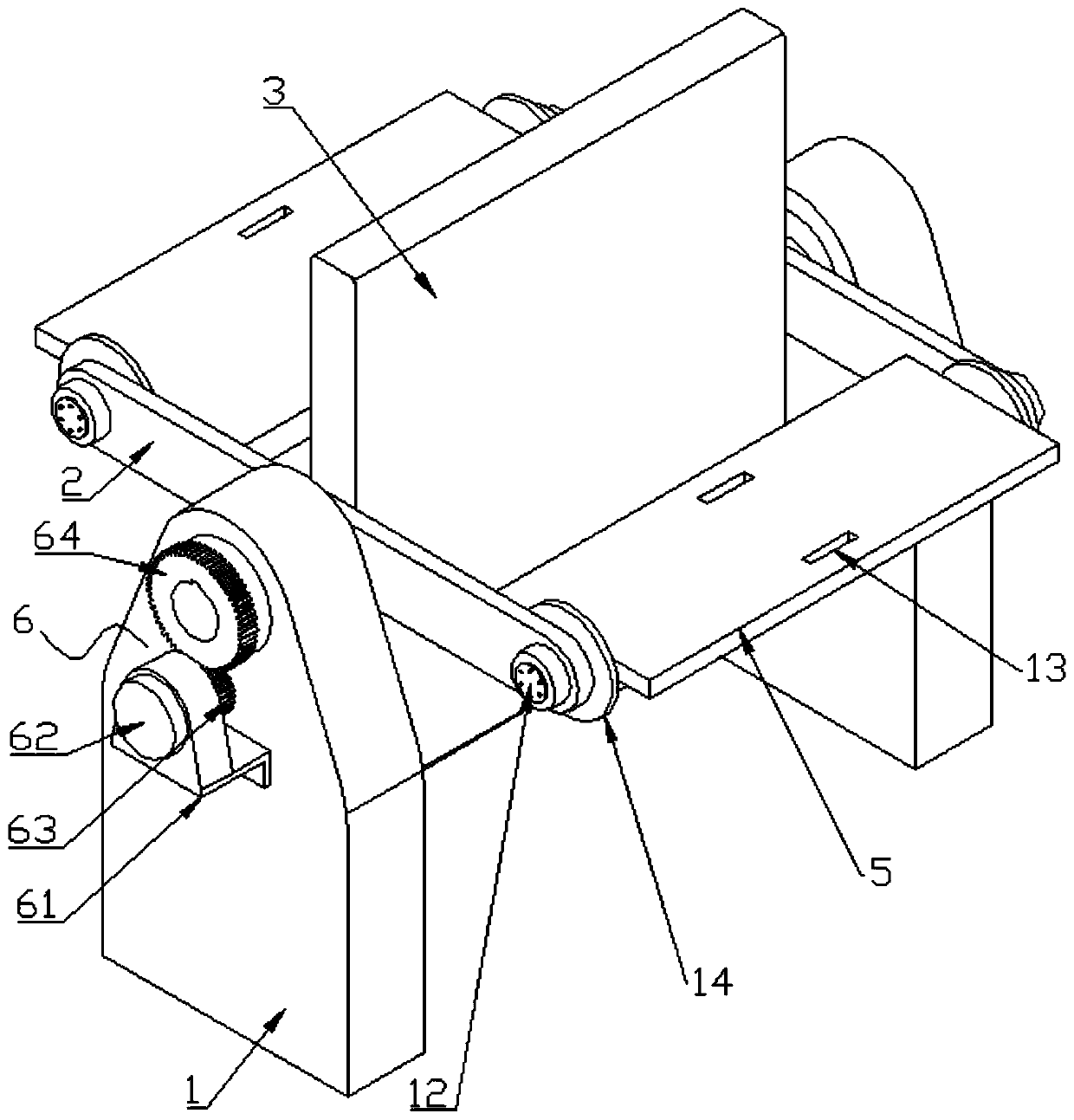

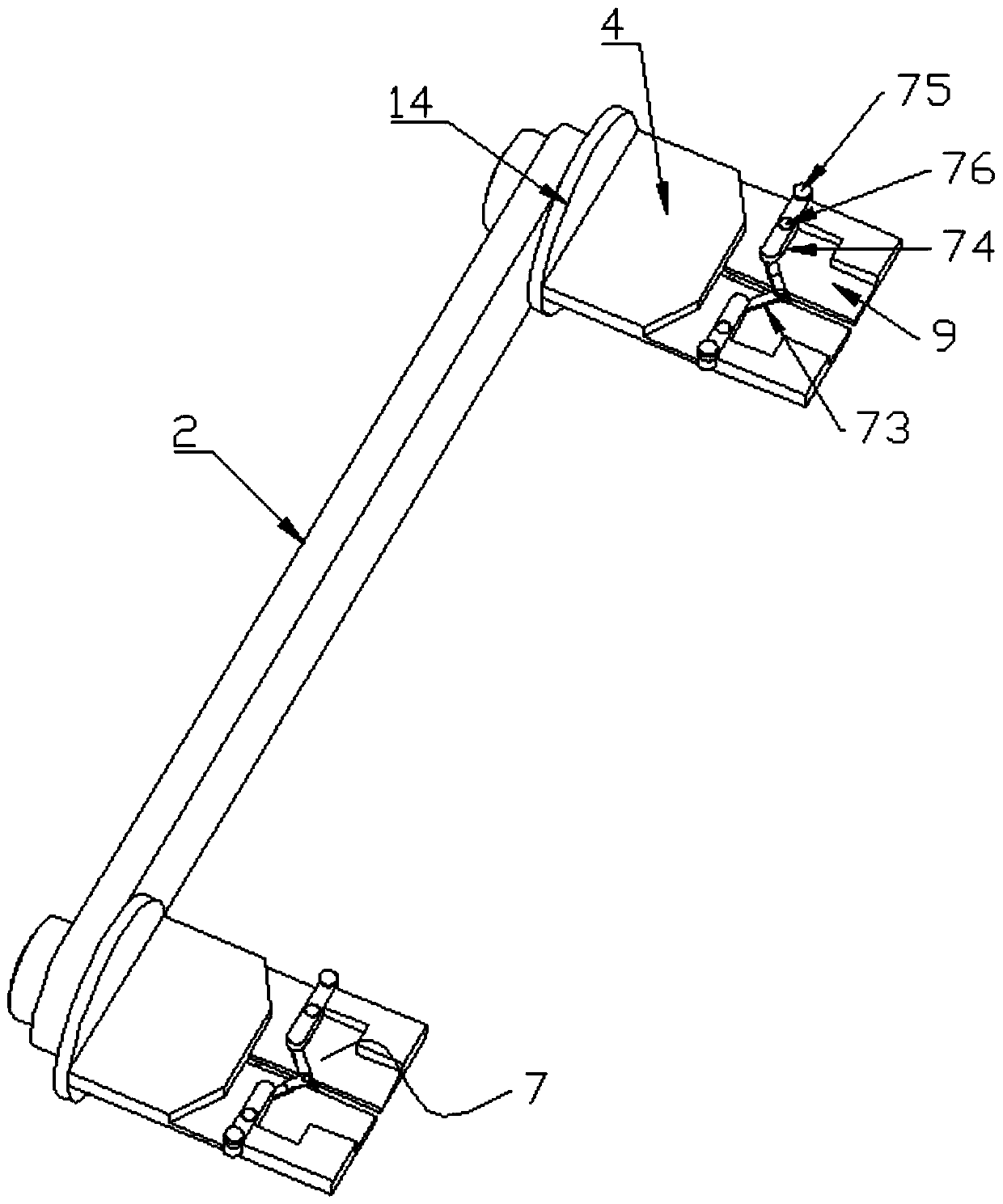

[0030] Such as Figure 1 to Figure 6 As shown, a new type of automobile chassis quick-change robot welding station includes a base 1, a rotating bracket 2, a partition 3, a supporting platform 4, and a fixture 5. The base 1 has two symmetrical arrangements, and the rotating bracket One end of 2 is rotatably connected to the base 1 through a bearing, and one of the bases 1 is equipped with a drive assembly 6 and can drive the slewing bracket 2 to rotate 360 degrees. The two ends of the slewing bracket 2 are also rotatably connected by bearings. A circular plate 14 is also connected between the support platform 4 and the revolving bracket 2 and is perpendicular to the support platform 4, which is used to separate the support platform 4 from the revolving bracket 2 and also serves as a clamp 5. For positioning, a locking mechanism 7 is installed on the supporting platform 4, the clamp 5 is arranged on the supporting platform 4 and locked and positioned by the locking mechanism 7...

Embodiment 2

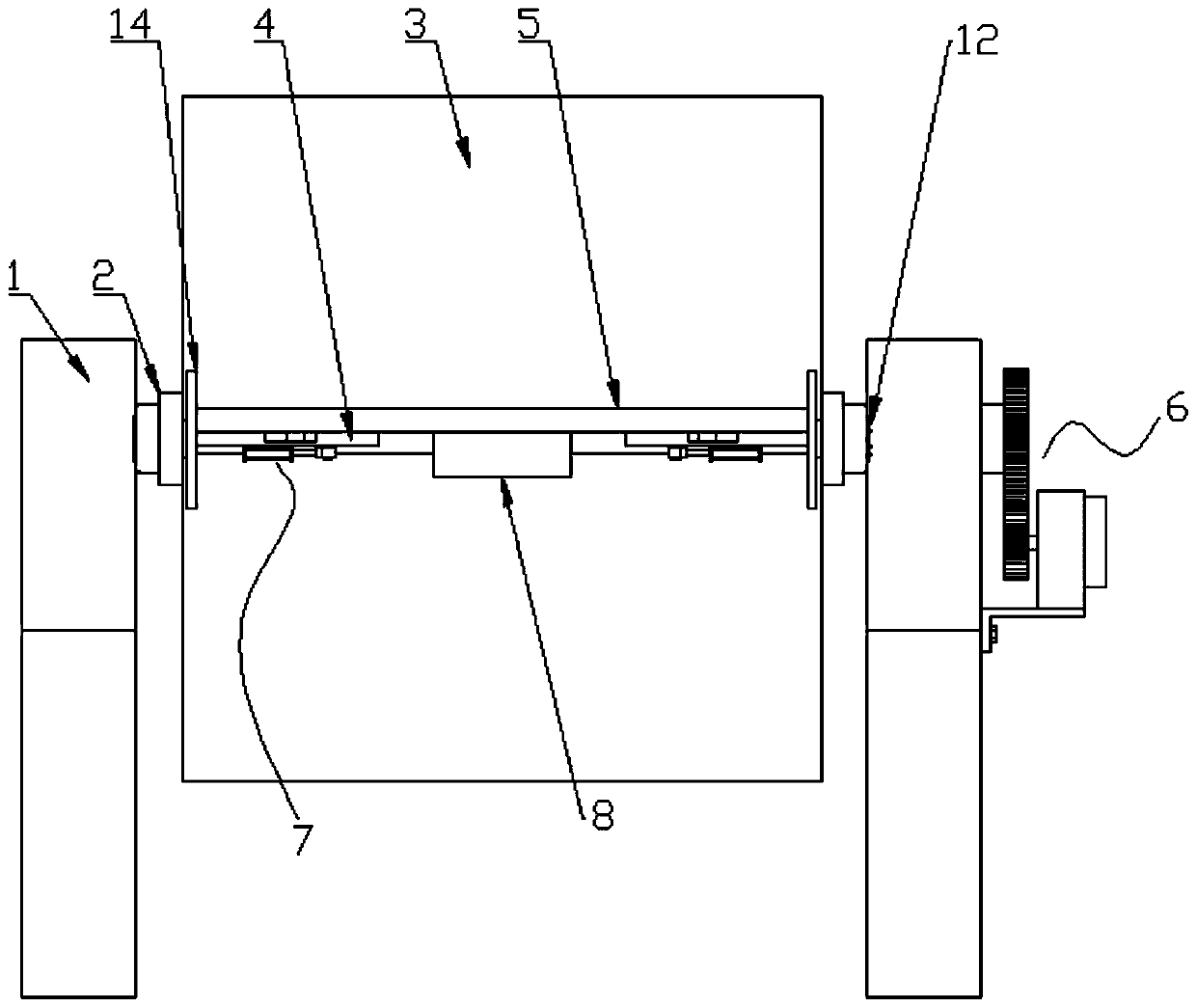

[0038] Such as Figure 7 As shown, a new type of automobile chassis quick-change robot welding station includes a base 1, a rotating bracket 2, a partition 3, a supporting platform 4, and a fixture 5. The base 1 has two symmetrical arrangements, and the rotating bracket One end of 2 is rotatably connected to the base 1 through a bearing, and one of the bases 1 is equipped with a drive assembly 6 and can drive the slewing bracket 2 to rotate 360 degrees. The two ends of the slewing bracket 2 are also rotatably connected by bearings. A circular plate 14 is also connected between the supporting platform 4 and the revolving bracket 2, which is perpendicular to the supporting platform 4, and is used to separate the supporting platform 4 from the revolving bracket 2, and also serves as a clamp 5. For positioning, a locking mechanism 7 is installed on the support platform 4, the clamp 5 is arranged on the support platform 4 and locked and positioned by the locking mechanism 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com