Integrated mechanical arm taking-out plate

A manipulator, one-piece technology, applied in the field of one-piece manipulator taking out plates, can solve the problems of poor stability of the manipulator, heavy take-out plate weight, large load, etc., and achieve the effects of convenient processing, weight reduction, and load reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

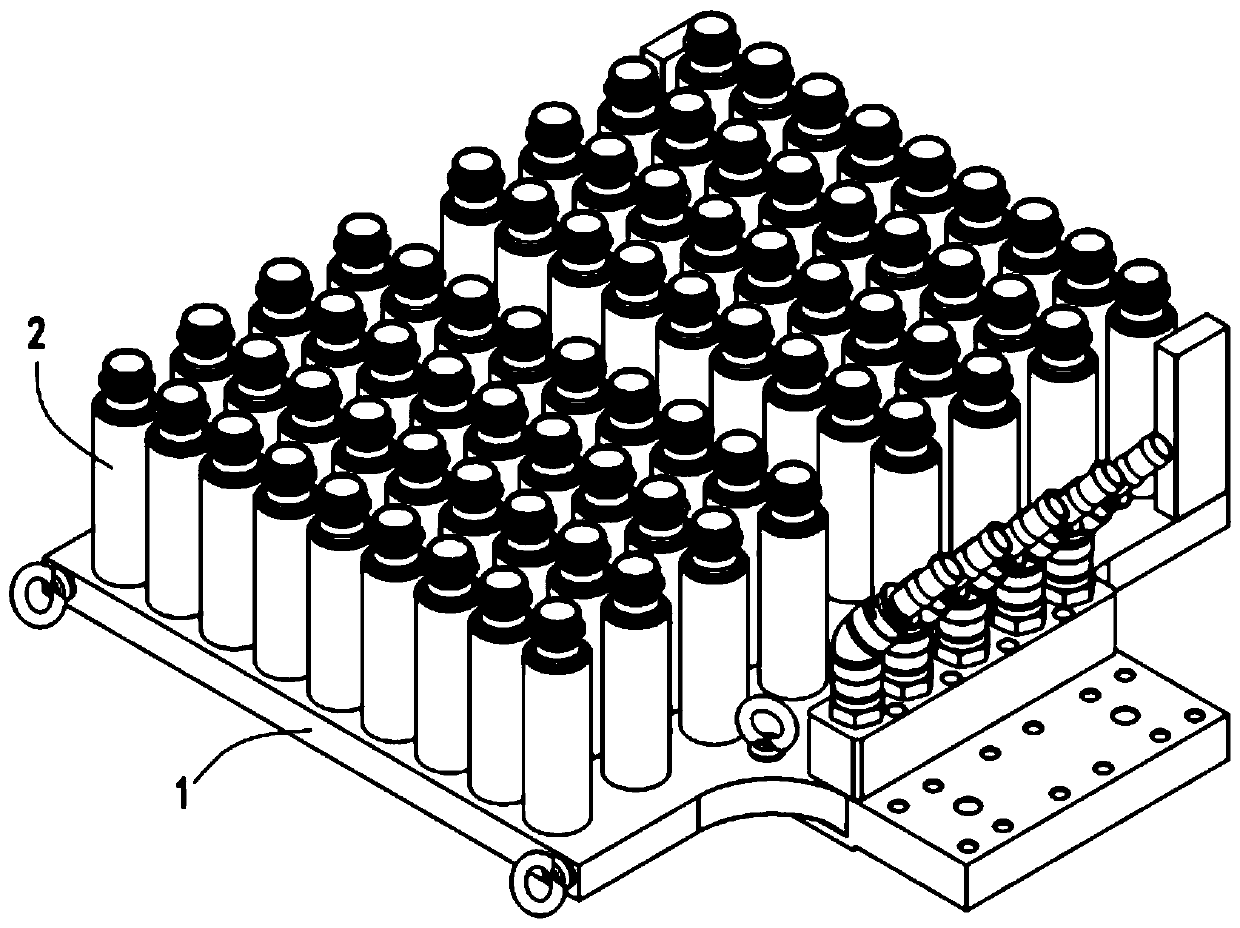

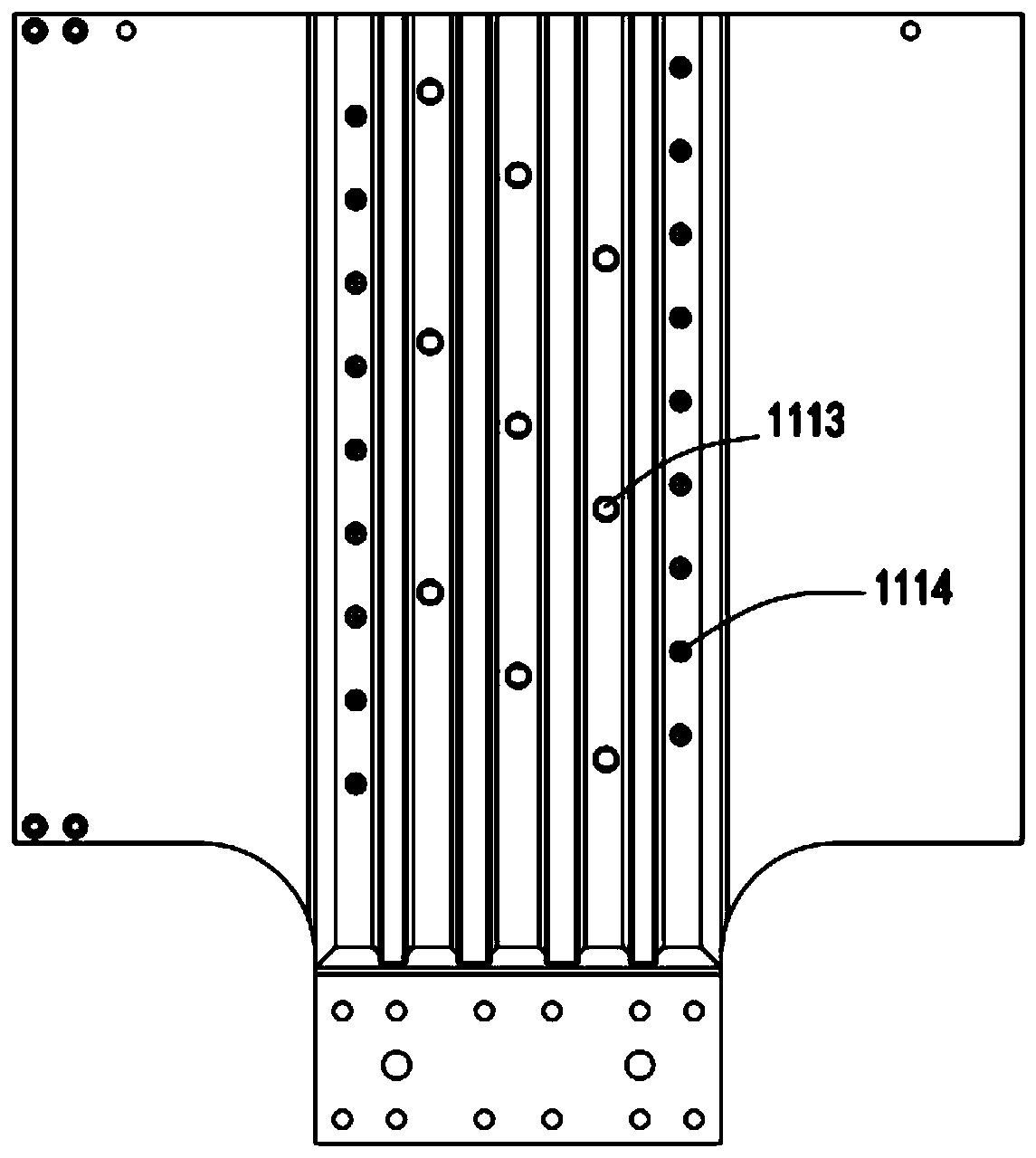

[0035] Such as Figure 1 to Figure 6 As shown, an integrated manipulator takes out the plate, including a bottom plate 1, and the bottom plate 1 includes a main board part 11 and a sub-board part 12. The branch channel 111 communicates with the main channel 121 opened at the junction of the main board part 11 and the sub-board part 12 .

[0036] It is worth mentioning that by processing an independent board to include the main board part 11 and the sub-board part 12, a branch channel 111 is opened on the main board part 11, and a branch channel 111 is opened at the junction of the main board part 11 and the sub-board part 12. The main flow channel 121, compared with the existing way of combining two plates, greatly reduces the weight of the embryo taking manipulator to take out the plate, especially when dealing with multi-cavity manipulators, it reduces the load of the manipulator cantilever and improves the manipulator. job stability

[0037] Further, the thickness of the ...

Embodiment 2

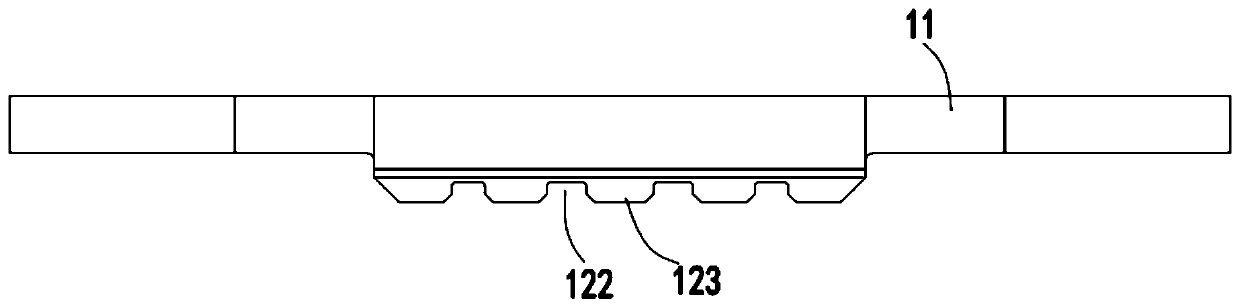

[0048] Such as figure 2 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: the surface of the sub-plate part 12 is provided with a groove 122 between two adjacent main channels 121, and a protrusion is formed between two adjacent grooves 122 part 123 , the main flow channel 121 is set at the middle position in the width direction of the raised part 123 .

[0049] It should be pointed out that by opening a groove 122 between two adjacent main channels 121 on the surface of the sub-plate part 12, it further reduces the weight of the taken-out plate without affecting the structural strength, and improves the operation efficiency of the manipulator. stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com