A carbon fiber composite material deep diving pressure chamber and its preparation method

A composite material and composite material layer technology, which is applied in the field of equipment materials, can solve the problems of inability to meet the requirements of deep water pressure chambers, unsatisfactory mass/displacement ratio, and inability to use composite material pressure chambers, so that the production technology can be easily mastered. , significant crack growth, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In this embodiment, after the overall three-dimensional weaving of the pressure chamber, the deep diving pressure chamber has a length of 1000 mm, an inner diameter of 200 mm, a weaving thickness of 25 mm, T800 carbon fiber as the yarn, a polyurethane waterproof layer thickness of 1.2 mm, and an epoxy resin content of 1.2 mm. 40%.

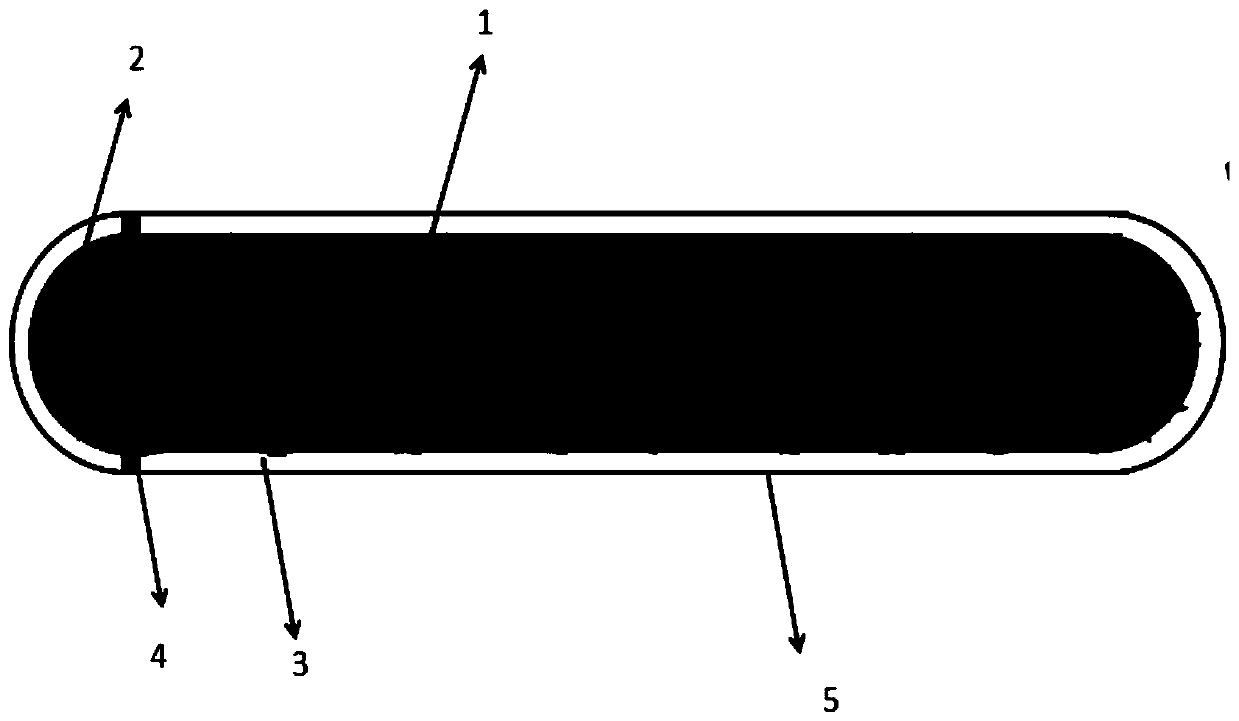

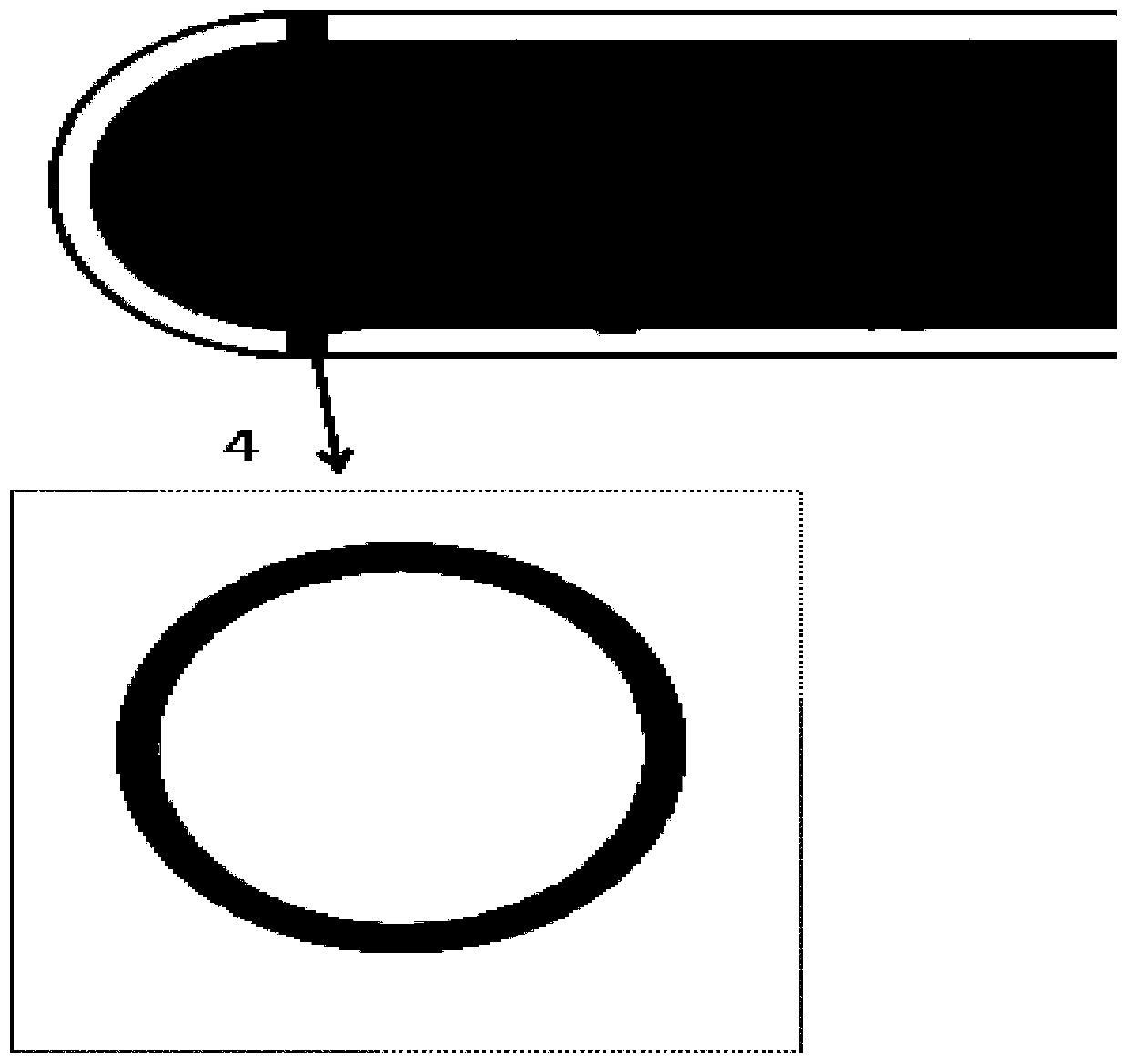

[0051] like figure 1 shown is a schematic structural diagram of the pressure chamber of the present invention, a three-dimensional braided composite material pressure chamber for an underwater glider, the deep diving pressure chamber includes a hemispherical shell end cover and a cylindrical shell with a hemispherical shell at one end, The hemispherical shell end cover and the cylindrical shell with a hemispherical shell at one end are connected by a rubber ring and a sealing ring; the hemispherical shell end cover and the cylindrical shell with a hemispherical shell at one end both include a carbon fiber composite material layer and a water...

Embodiment 2

[0061] The overall three-dimensional braiding of the pressure chamber in this embodiment has a length of 2200mm, an inner diameter of 400mm, and a braiding thickness of 40mm. The yarn is T800 carbon fiber, the thickness of the polyurethane waterproof protective layer is 1.2mm, and the epoxy resin is used. The content is 40%.

[0062] The specific preparation steps are:

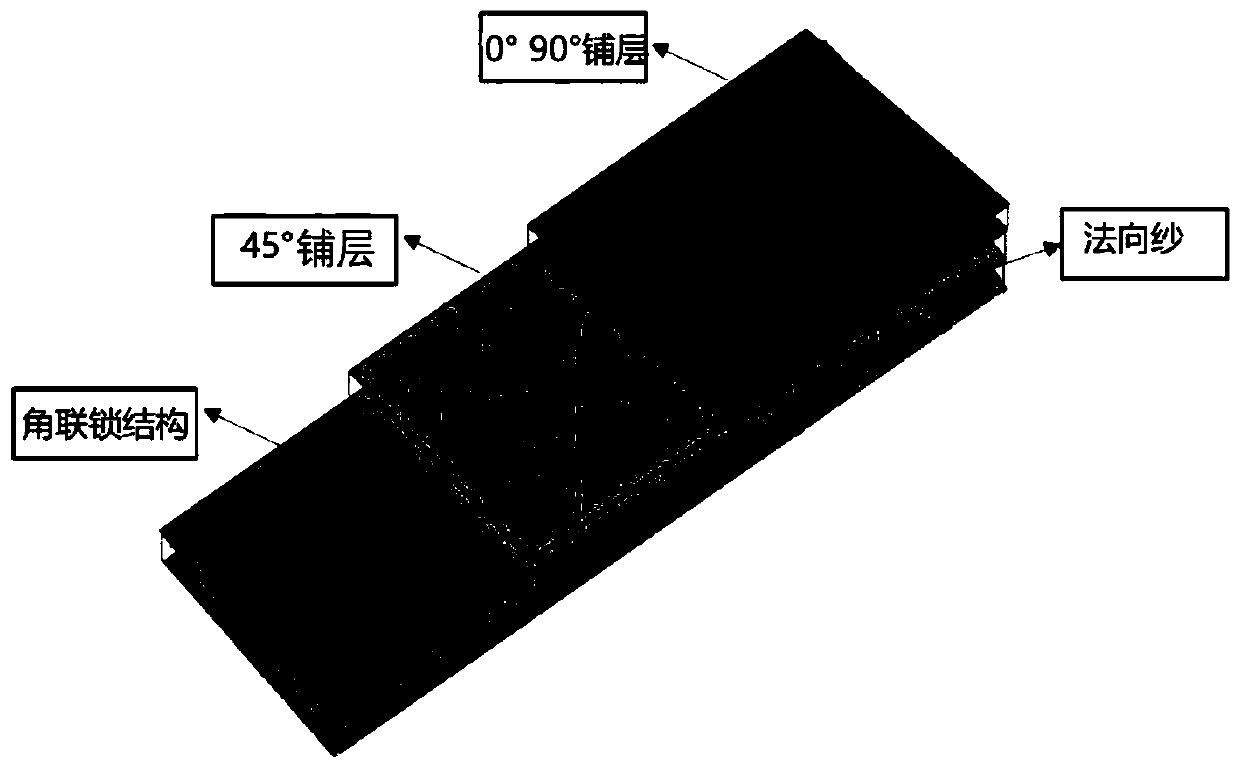

[0063] (1) According to the drawing requirements of the pressure chamber body, the cylindrical shell with a hemispherical shell at one end is integrally weaved by three-dimensional weaving technology. The deep-dive carbon fiber composite pressure chamber has an orthogonal three-dimensional interwoven surface layer yarn interwoven structure of a cylindrical shell with a hemispherical shell at one end. The pressure chamber thickness ratio is 35%, and the quasi-anisotropic three-dimensional interwoven transition layer in the pressure chamber surface of the deep-dive carbon fiber composite material includes four ...

Embodiment 3

[0069] The pressure chamber in this embodiment has a length of 1800mm, an inner diameter of 300mm, and a weaving thickness of 30mm. The yarn is made of T800 carbon fiber, the thickness of the polyurethane waterproof protective layer is 1.2mm, and the thickness of the epoxy resin is 1.2mm. The content is 40%.

[0070] The specific preparation steps are:

[0071] (1) According to the drawing requirements of the pressure chamber body, the cylindrical shell with a hemispherical shell at one end is integrally weaved by three-dimensional weaving technology. The deep-dive carbon fiber composite pressure chamber has an orthogonal three-dimensional interwoven surface layer yarn interwoven structure of a cylindrical shell with a hemispherical shell at one end. The pressure chamber thickness ratio is 35%, and the quasi-anisotropic three-dimensional interwoven transition layer in the pressure chamber surface of the deep-dive carbon fiber composite material includes four series of yarns o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com