Convenient-to-disassemble durable industrial conveying chain

A conveyor chain and dismantling technology, which is applied in the field of convenient dismantling durable industrial conveyor chains, can solve problems such as fatigue loosening of components, chain elongation, and poor matching effect of sprockets, so as to reduce maintenance and procurement costs, and reduce overheating. Fast wear condition, the effect of maintaining fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

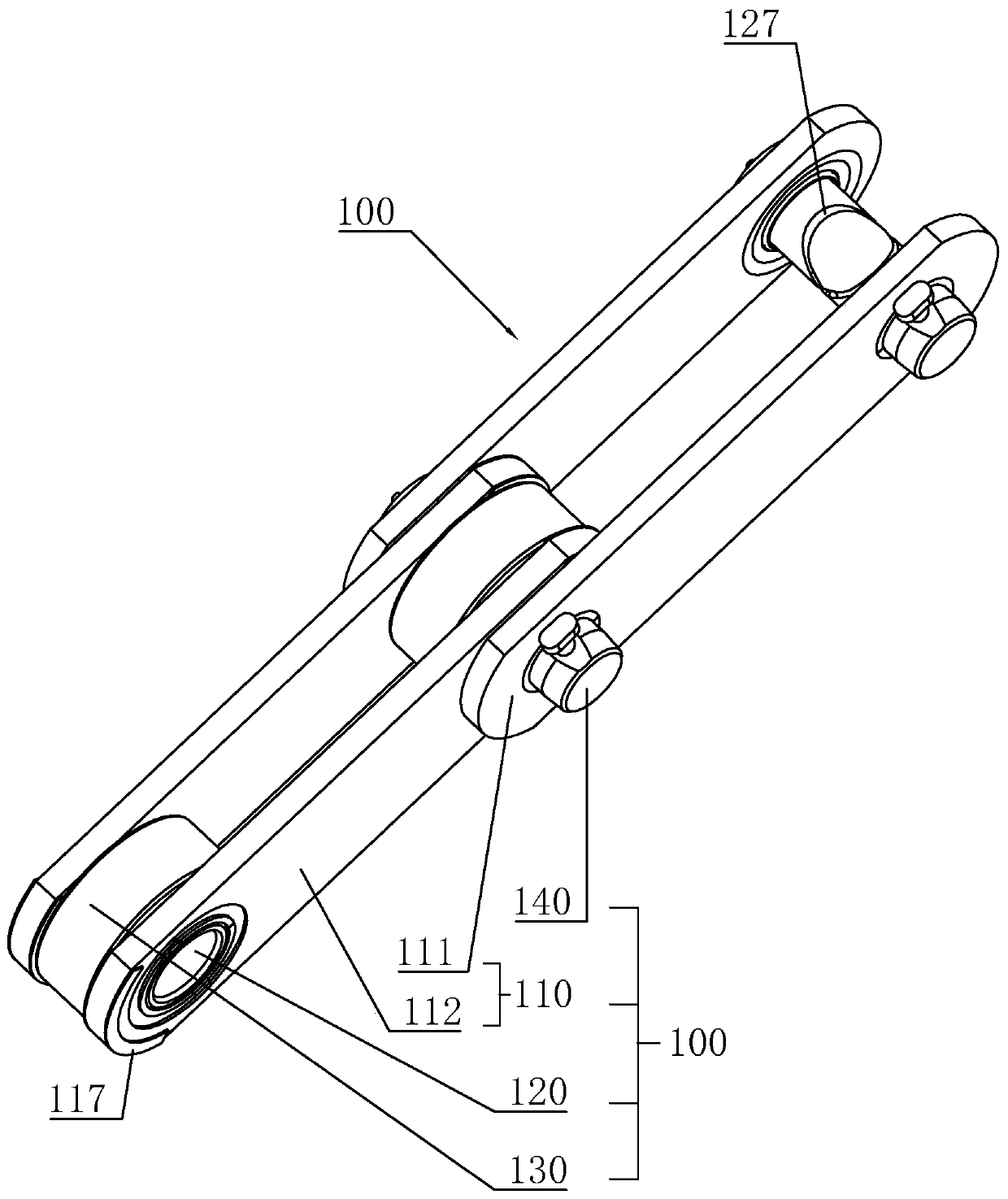

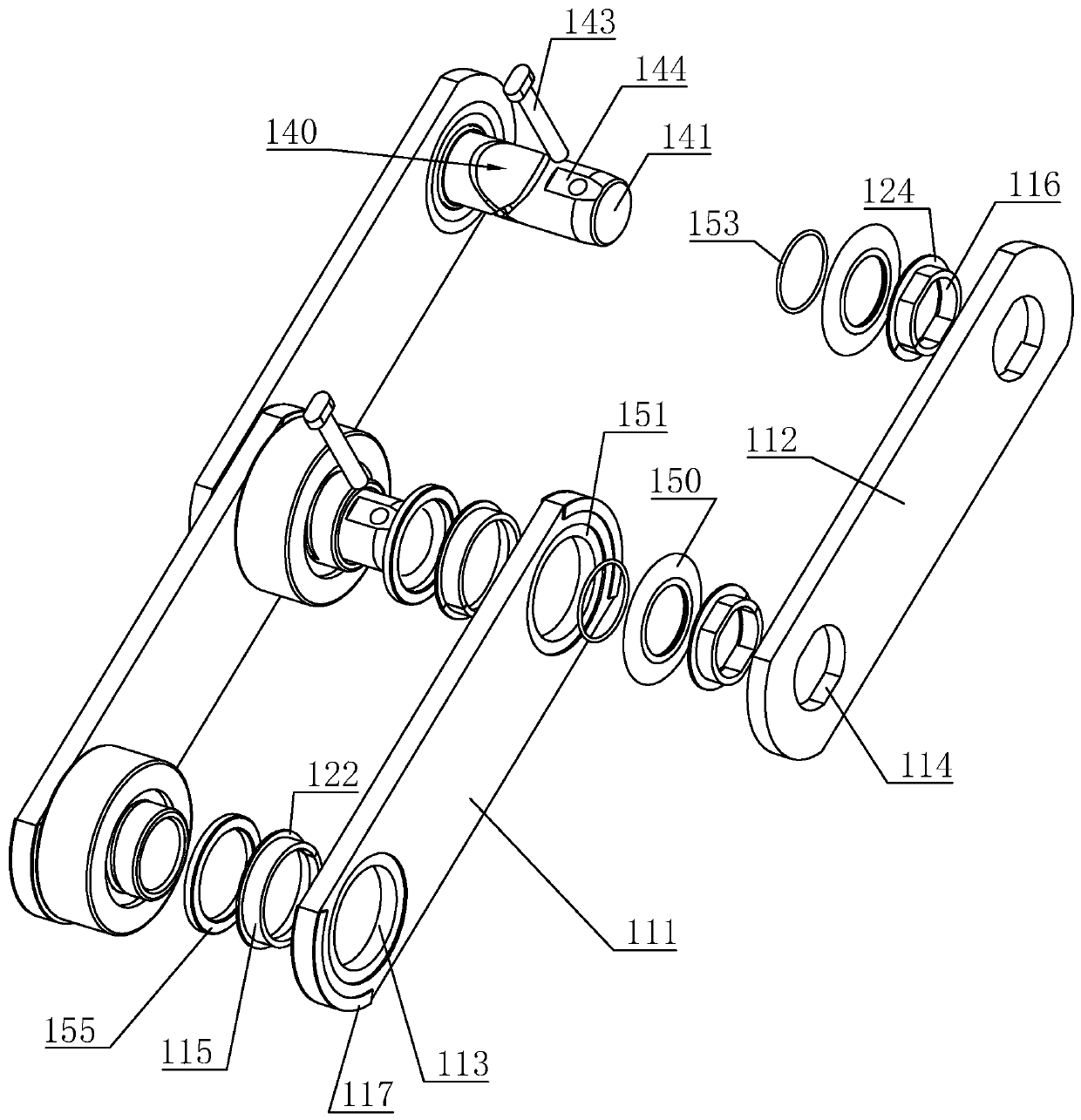

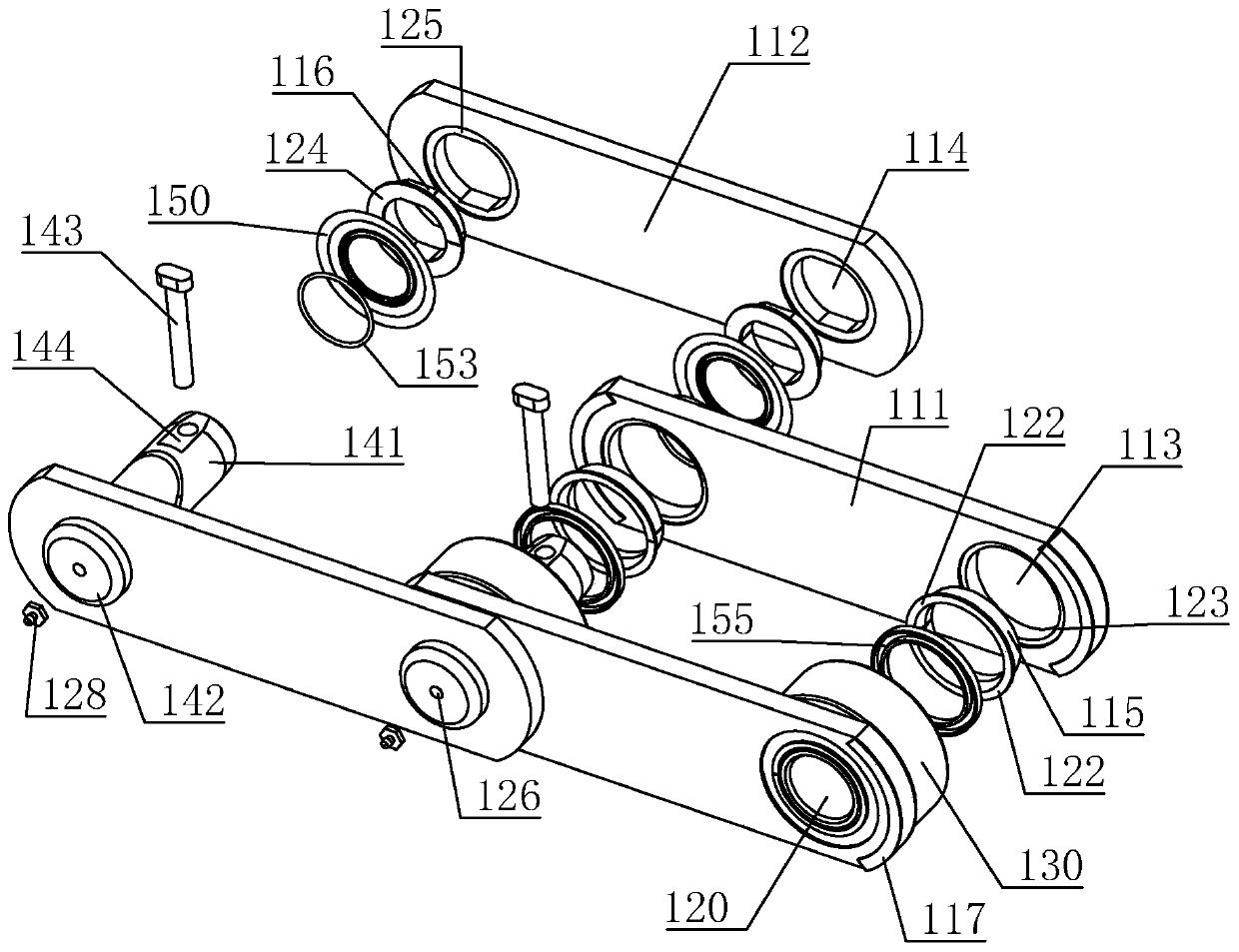

[0045] A convenient detachable durable industrial conveyor chain, comprising a plurality of sequentially connected chain links 100, the chain link 100 includes a chain plate group 110, a sleeve 120, a roller 130 and a pin shaft 140, and the chain plate group 110 includes two spaced sets The inner chain piece 111 and two outer chain pieces 112 arranged at intervals, the two inner chain pieces 111 are located inside the two outer chain pieces 112, the inner chain piece 111 is connected end to end with the outer chain piece 112, and the sleeve 120 is arranged on two Between the inner chain pieces 111 , the roller 130 is sleeved on the sleeve 120 , and the pin shaft 140 passes through the inner chain piece 111 and the outer chain piece 112 .

[0046] Both ends of the inner chain piece 111 are provided with a sleeve clamping hole 113, and the sleeve clamping hole 113 is embedded with an inner chain piece ferrule 115, the inner chain piece ferrule 115 has a gap, and the inner chain p...

Embodiment 2

[0057] A convenient detachable durable industrial conveyor chain, the difference from Embodiment 1 is that a plurality of inverted cone-shaped oil storage holes 160 are opened on the circumferential side wall of the sleeve 120 in the axial direction, and the oil storage holes 160 are arranged along the circumferential direction. There are multiple rows, and the edges of the oil storage holes 160 are provided with chamfered slopes, and the oil storage holes 160 in two adjacent rows are alternately arranged.

[0058] The beneficial effect of this embodiment is that: first add grease to the oil storage hole 160 during installation, while the roller 130 is constantly rotating, after its temperature continues to rise, the grease melts to form lubricating oil, and the lubricating oil can be released from the storage The oil hole 160 is carried out, which reduces the friction between the sleeve 120 and the roller 130, so that it can rotate better, prevents it from wearing out too quic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com