a cloth machine

The technology of a spreading machine and a frame is applied in the field of clothing production equipment, which can solve the problems of consuming more electric energy and high processing costs, and achieve the effects of facilitating subsequent processing, reducing processing costs, and smoothing the fabric.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

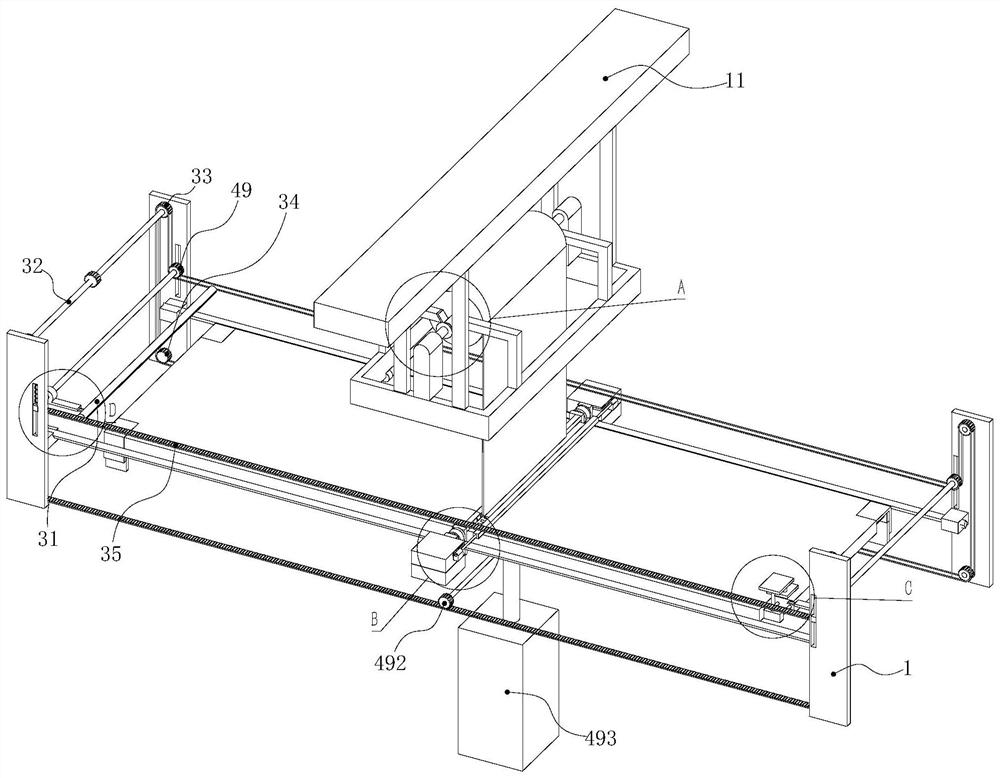

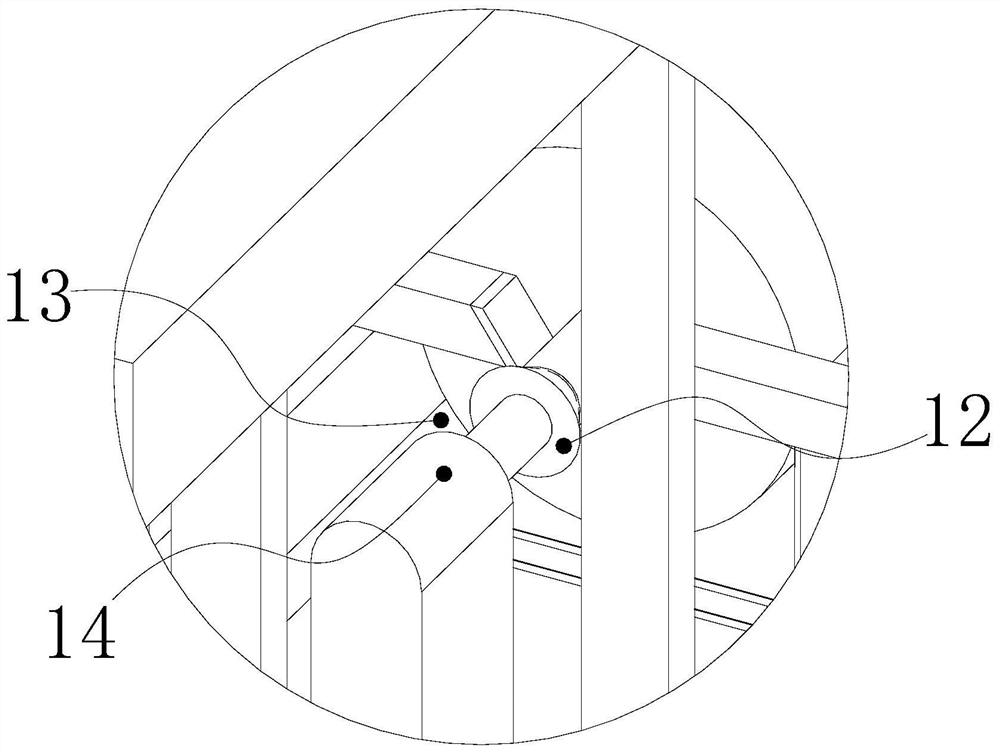

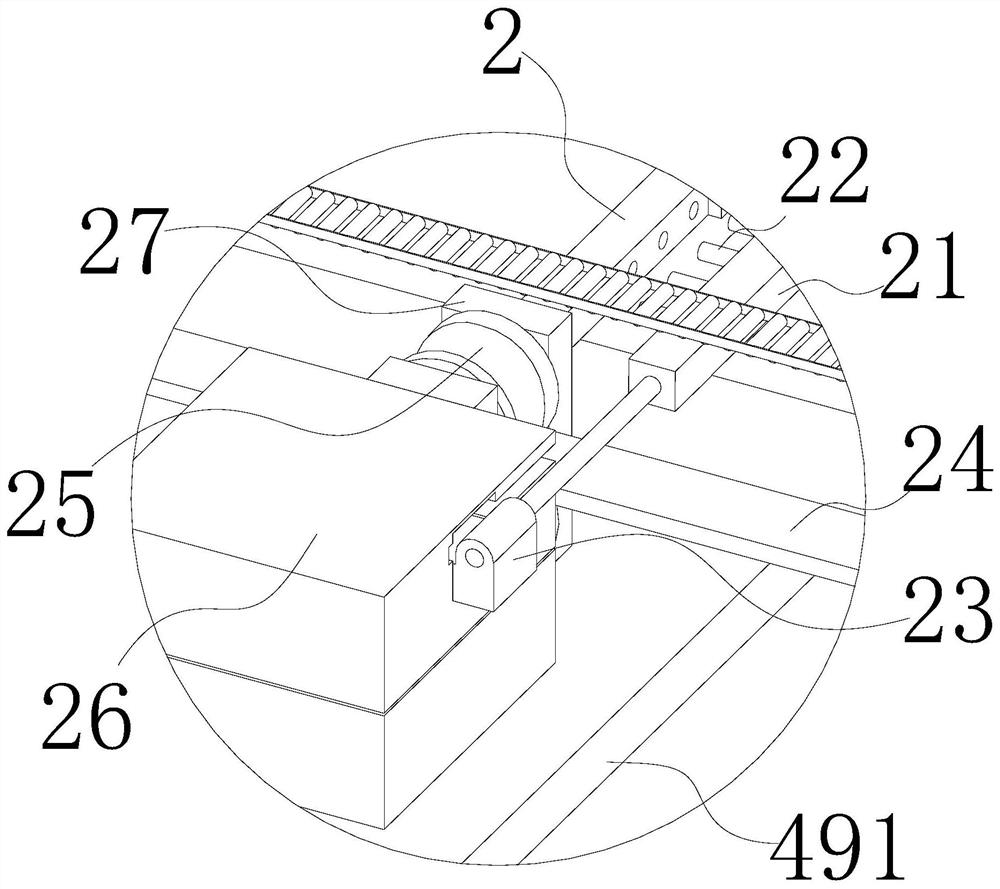

[0018] Such as Figure 1-5 As shown, a cloth spreading machine includes a frame 1, a fixing device, a blanking device, a cloth pulling device and a cutting device, and the fixing device includes a fixed frame 11, a push block 12, a guide roller 13 and a first driving member 14. The fixed frame 11 is provided with slots for the two ends of the cloth roller to be snapped into, so as to prevent the cloth roller from coming out during the rotation; the first driving member 14 is selected from a cylinder, and is symmetrically fixed on the fixed frame, and the push block 12 Rotationally connected to the output shaft of the first driver, and set corresponding to the card slot, then the position of the distribution roller can be adjusted by pushing the push block through the first driver, so that the middle part of the distribution roller is aligned with the middle part of the workbench, which is convenient for subsequent processing; Described guide roller 13 selects conventional roun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com