A paper palletizer

A palletizer and paper technology, applied in the field of printing paper palletizing equipment, can solve the problems of increasing the complexity of the equipment structure, increasing the area of the equipment, and being unfavorable to work efficiency, so as to shorten the time of a single operation and improve the work efficiency. Efficiency and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

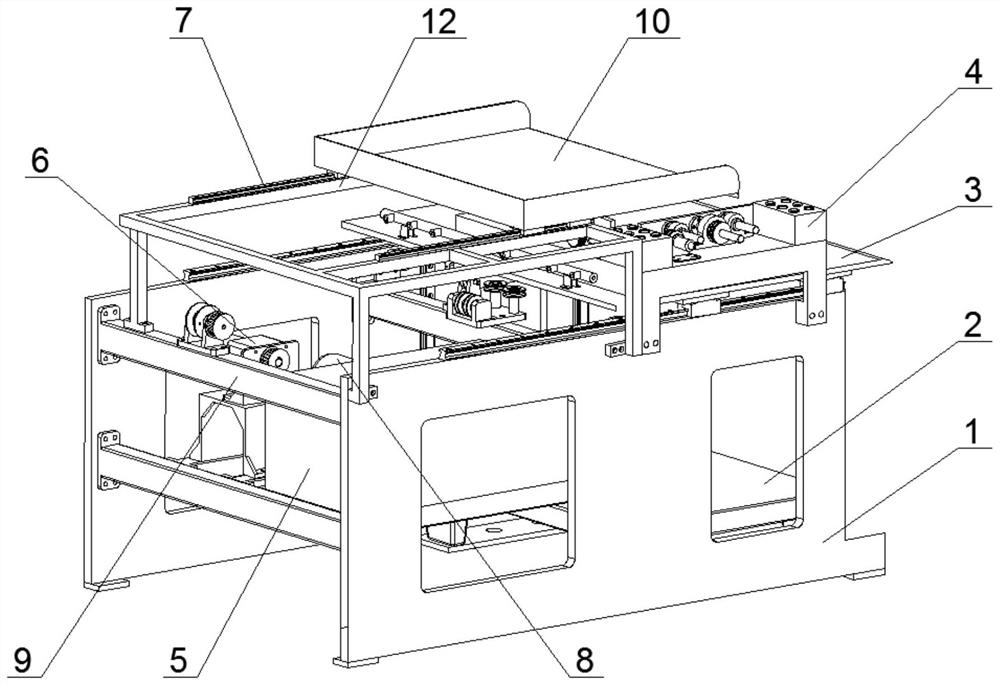

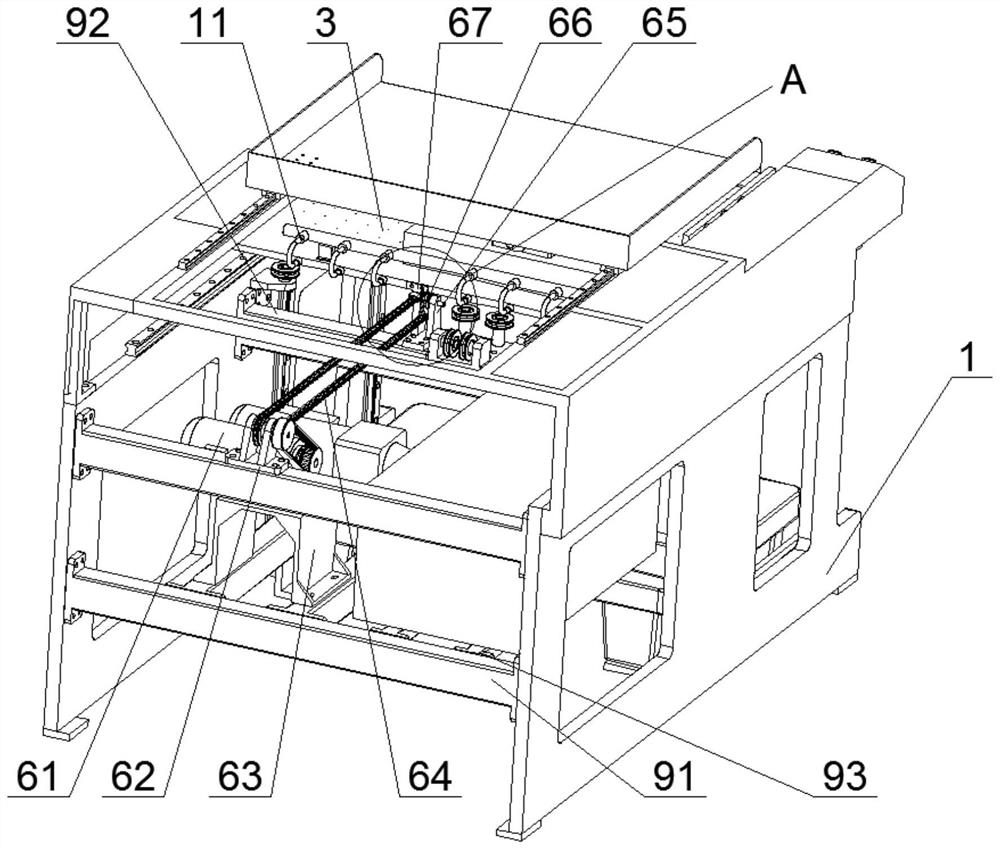

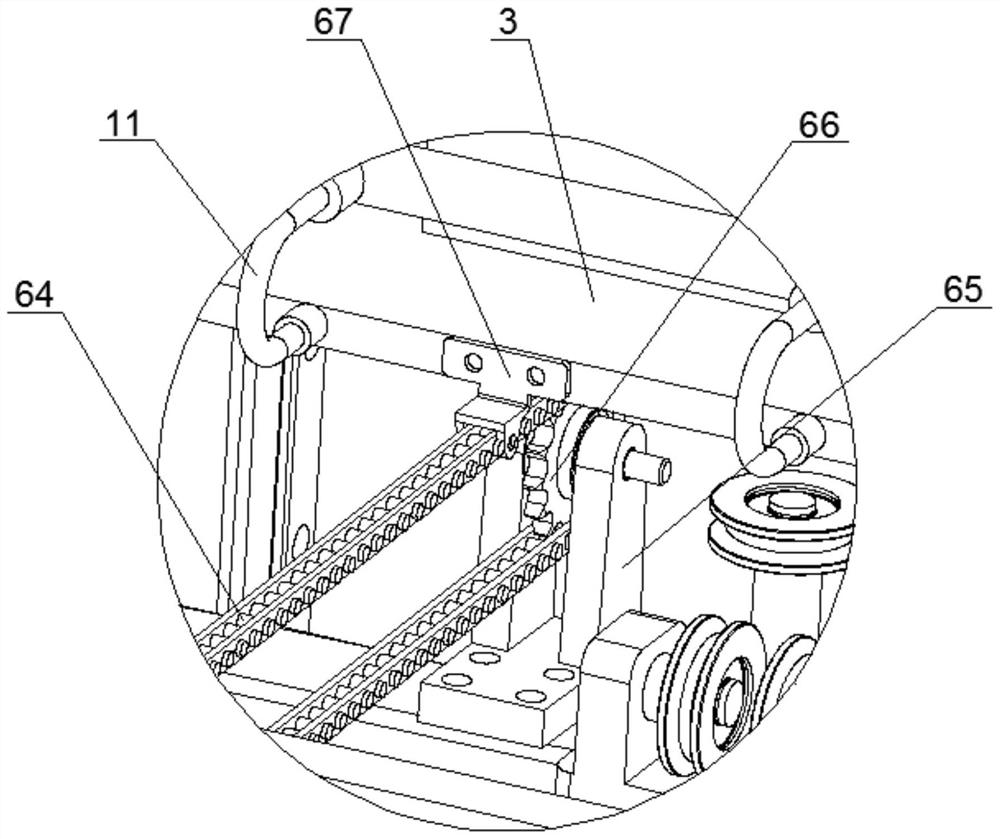

[0022] Such as Figure 1 to Figure 6 As shown, the paper palletizer provided in this embodiment includes a frame, an electric control cabinet 5 arranged on the frame, and a paper splicing platform 3 arranged on the upper part of the frame, in order to reduce the floor space of the equipment and the complexity of the mechanism To some extent, in this embodiment, the frame includes frame plates 1 on both sides and support beam groups 9 fixed between the frame plates 1 on both sides. Certainly, the composition forms of the support beam groups 9 are various. The ratio of the structural complexity of the support beam group 9 as a whole to its floor area is optimized. The support beam group 9 includes two layers of frame beams, and each layer of frame beams includes a front beam 91, a rear beam 92, and a front beam fixed on the front beam. A plurality of support beams 93 between the cross beam 91 and the rear cross beam 92 . The top of the frame plate 1 is fixed with a U-shaped sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com